Table of Contents

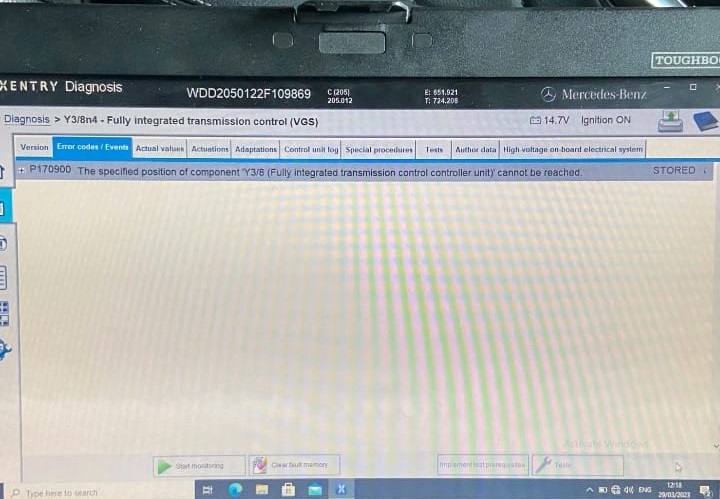

Case Study: Car Jerks When Shifting from Park to Drive (Mercedes-Benz C300 W205, 7G-Tronic)

A sharp jerk when shifting from Park (P) to Drive (D) is more than an annoyance it’s an early warning that the hydraulic controls or adaptations in your 7G-Tronic may be out of spec. Left unresolved, this can accelerate clutch wear and lead to costly repairs.

This article guide breaks down a real C300 W205 case with D→P engagement jerk, the P170900 fault, and the fix: valve body (VGS/mechatronics) service and solenoid restoration.

Quick Snapshot (Vehicle & Complaint)

| Item | Detail |

|---|---|

| Model | Mercedes-Benz C300 W205 |

| Transmission | 7G-Tronic (722.9) with VGS (Y3/8) |

| Complaint | Jerk when shifting P → D; occasional delay between gears |

| Key DTC | P170900 – Specified position of Y3/8n4 (Fully Integrated Transmission Control/VGS) cannot be reached |

| Root Cause (this case) | Contamination/wear in valve body; solenoids out of spec; adaptations drifted |

| Fix | Valve body removed, deep cleaned + worn solenoids replaced, ATF/filter renewed, adaptations completed |

What P170900 Means (Plain English)

The 7G-Tronic’s VGS (electro-hydraulic control) uses solenoids to achieve precise clutch and range positions. P170900 indicates that a commanded hydraulic position couldn’t be reached within limits. Common reasons:

- – Sticky or weak solenoids

- – Contaminated valve body channels

- – Incorrect ATF level/condition

- – Less often: wiring/connectors to the VGS

When the system can’t hit its target quickly, you feel a thump/jerk when selecting D.

Symptoms & Likely Causes

| Symptom | Likely Cause(s) | First Things to Check |

|---|---|---|

| Jerk when selecting P → D | Valve body contamination, sticky solenoids, adaptations off | ATF level/condition; DTCs; adaptation status |

| Delay engaging D/R | Low/old ATF; internal leakage; weak solenoids | Fluid level at temp; pan/filter condition |

| Intermittent harsh up/down shifts | Solenoid modulation off; mounts amplifying feel | Solenoid tests; engine/trans mount inspection |

| Jerk only when cold | Higher fluid viscosity + borderline solenoids | Warm to spec, recheck; consider service |

| New after battery work | Lost learned values | Perform standstill/running adaptations |

Diagnostic Workflow (What We Did)

1. XENTRY short test & freeze frames

Confirmed P170900 and reviewed ranges/adaptation counters.

2. Prerequisites

- – Battery/charging stable (12.5–14.5 V)

- – ATF in temperature window for level check

3. Connector & harness sanity

Inspected transmission plug for fluid wicking, pin tension, corrosion.

4. ATF/pan inspection

Dropped the pan: found sludge/debris; filter aged.

5. Valve body decision

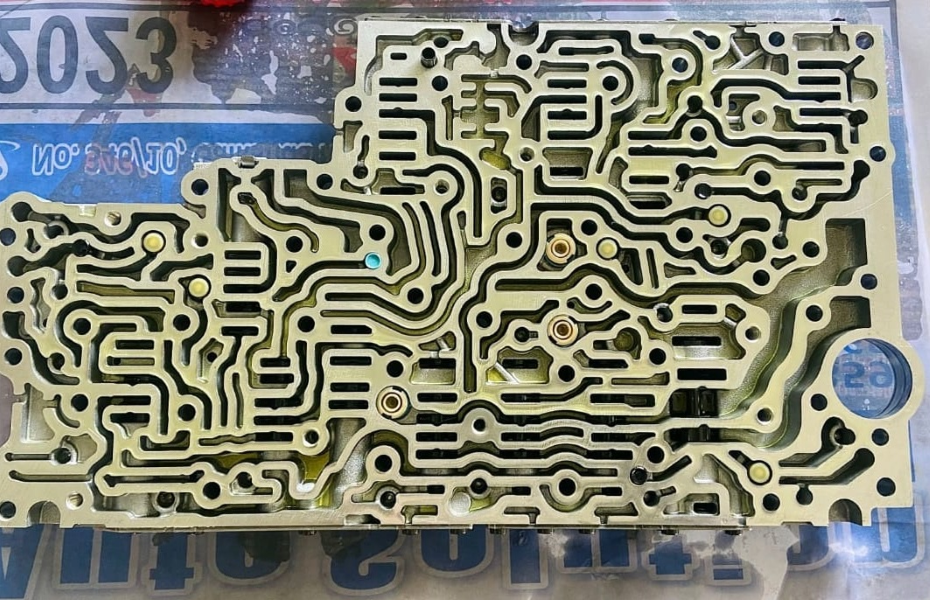

Given P170900 + physical contamination, proceeded to remove valve body (VGS) for service.

6. Solenoid & channel service

Cleaned channels with fresh ATF, replaced worn solenoids, verified actuation “click” feedback off-car.

7. Reassembly & fill

New filter, pan gasket, correct MB-spec ATF, level set at temperature.

8. Adaptations

Completed standstill and running adaptations per XENTRY prompts.

9. Validation road test

Multiple P→D/D→R cycles, stop-and-go, highway—no jerk, shifts crisp.

Case Study Details: What We Found & Fixed

Customer report: Jerk every time P→D; increasing in intensity over weeks, occasional overall “lazy” shifting.

Scan result: P170900 tied to the VGS (Y3/8n4).

Disassembly findings:

- – Valve body passages contaminated

- – Several solenoids showing response lag/wear

Repair: Full valve body clean, solenoid replacement, new filter/pan gasket, MB-spec ATF, adaptations.

Post-repair: Jerk eliminated; smooth engagements and gear changes; DTC memory clean.

Symptom → Cause → Fix (Reference Table)

| Symptom | Likely Cause | Recommended Fix |

|---|---|---|

| P→D jerk, worse when warm | Sticky solenoids; varnish in channels | Valve body clean; replace weak solenoids |

| P→D jerk + delay into R | Low/old ATF; clogged filter | ATF/filter service; set level at temp |

| Harsh shifts after battery disconnect | Lost learned values | Standstill + running adaptations |

| Persistent harshness after service | Incorrect ATF spec/level; mount wear | Verify fluid spec/level; inspect mounts |

| DTC P170900 returns | Internal VGS fault (less common) | Replace VGS/valve body assembly; re-adapt |

Explore More Mercedes Transmission Issues

For a deeper dive into gearbox problems slipping into Neutral, delayed/harsh shifts, “Not in P” warnings, and hybrid faults visit our hub: Mercedes Transmission Issues – Causes and Fixes. You’ll find grouped case studies, step-by-step diagnostics, symptom–cause–fix tables, and prevention tips to resolve shifting issues quickly and confidently.

DIY vs Professional (Be Realistic)

| Task | DIY-Friendly | Pro Recommended | Why |

|---|---|---|---|

| Read/clear codes, basic scan | OK | Good first step | |

| Check ATF level (temp-based) | OK | Needs exact temp & procedure | |

| Replace pan gasket/filter | OK | Risk of leaks/level errors | |

| Valve body removal/solenoid work | OK | Clean-room care & torque specs | |

| XENTRY adaptations | OK | OE tool + strict prerequisites |

Cost & Time (Indicative)

| Operation | Typical Time | Notes |

|---|---|---|

| Diagnosis & road logging | 1.0–1.5 h | Replicate P→D jerk; freeze frames |

| Valve body R&R + service | 3–5 h | Model packaging varies |

| ATF/filter & level set | 0.8–1.2 h | MB-spec fluid only |

| Adaptations + road test | 0.5–1.0 h | Requires stable voltage & ATF temp |

Total cost depends on labor rates, number of solenoids replaced, and ATF volume.

After the Fix: Verification Steps

- – Cycle P → R → N → D several times at operating temp no clunks/jerks.

- – Short urban loop + highway merge; confirm smooth tip-in and no flare.

- – Final XENTRY scan: no current or stored drivetrain DTCs.

- – Check for leaks after heat soak and the next morning (cold start).

Prevention & Maintenance

- – ATF & filter service at sensible intervals (many specialists: 60–80k km / 4–5 years), even if “lifetime.”

- – Avoid prolonged idling/heat-soak followed by aggressive launches.

- – Keep battery/charging healthy; low voltage corrupts adaptations.

- – If a jerk appears after any battery/software work, run adaptations promptly.

- – Address mount wear collapsed mounts amplify perceived harshness.

FAQs: Car Jerks When Shifting From Park to Drive

1) Why does my Mercedes jerk when shifting from Park to Drive?

Because the commanded hydraulic position isn’t achieved smoothly commonly from sticky solenoids, contaminated valve body channels, or lost adaptations. The TCU over- or under-shoots pressure, causing a thump.

2) Will a fluid change alone fix it?

If the cause is borderline ATF or a clogged filter, it can help. But P170900 tied to VGS position control often needs valve body cleaning and solenoid restoration plus adaptations.

3) What are “adaptations,” and why do they matter?

Adaptations are the TCU’s learned values for clutch fill times and overlap. After repairs or voltage loss, you must run standstill/running adaptations so the box re-learns smooth engagements.

4) Can I keep driving if the jerk is mild?

Short term, maybe but every harsh engagement stresses clutches and mounts. Fix it early to avoid bigger bills.

5) Do I need a new transmission?

Rarely. Most P→D jerks are resolved with valve body service, solenoids, correct ATF, and adaptations. Only severe mechanical wear requires deeper work.

6) I replaced the battery and now it jerks. Coincidence?

Probably not. Voltage loss can reset learned values. Run the prescribed adaptation routines.

7) Could engine or transmission mounts cause the jerk?

Mounts don’t cause the hydraulic fault, but worn mounts amplify the sensation. Inspect and replace if collapsed.

Conclusion

In this W205 C300, a persistent P→D jerk with P170900 pointed to valve body contamination and weak solenoid response. Cleaning the valve body, replacing worn solenoids, renewing ATF/filter, and completing adaptations restored factory-smooth engagements. Follow the scan → fluid → valve body → adaptations → verify sequence, and you’ll fix the problem once—properly.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: September 2025

Leave a Reply