Table of Contents

Car Will Turn But Not Start: Mercedes-Benz A-Class W177 ; Timing Fault Case Study

When a Mercedes-Benz A Class W177 turns over but won’t start, the culprits often hide in timing control, sensor signals, or fuel/ignition delivery. This real workshop case shows how an exhaust camshaft + camshaft adjuster fault on the M260 Engine created a no-start despite good cranking and how a structured diagnosis led to a clean fix.

Vehicle & Complaint

- Model: Mercedes-Benz A-Class W177

- Engine: M260

- Customer complaint: “Car will turn but not start.”

Diagnostic Path (Step-by-Step)

1. Short Test & DTCs

- – Faults logged for exhaust camshaft position → points to timing/VVT control or signal integrity.

2. Power & Ground to Sensor

- – Exhaust camshaft position sensor power supply: OK

- – Grounds: OK → sensor is powered correctly.

3. Signal Integrity

- – Sensor signal abnormal/unstable during crank.

- – Note: Bad timing can make a good sensor look bad.

4. Wiring & Resistance Checks

- – Harness continuity/resistance within spec → wiring not the root cause.

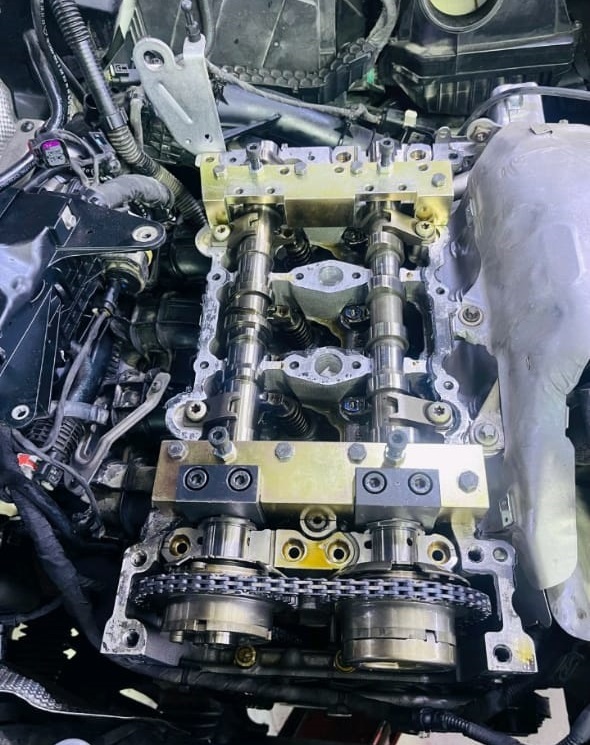

5. Mechanical Timing Verification

- – Opened for inspection.

- – Finding: Misalignment between exhaust camshaft and exhaust camshaft adjuster (phaser).

- – Result: ECU can’t reconcile crank/cam correlation → no start even with healthy cranking.

Root Cause

Mechanical misalignment/failure of the exhaust camshaft & exhaust adjuster (VVT phaser) on the M260 disrupting cam/crank sync and preventing start authorization/fuel timing.

Repair Procedure

Replaced:

- – Exhaust camshaft (OEM)

- – Exhaust camshaft adjuster/phaser (OEM)

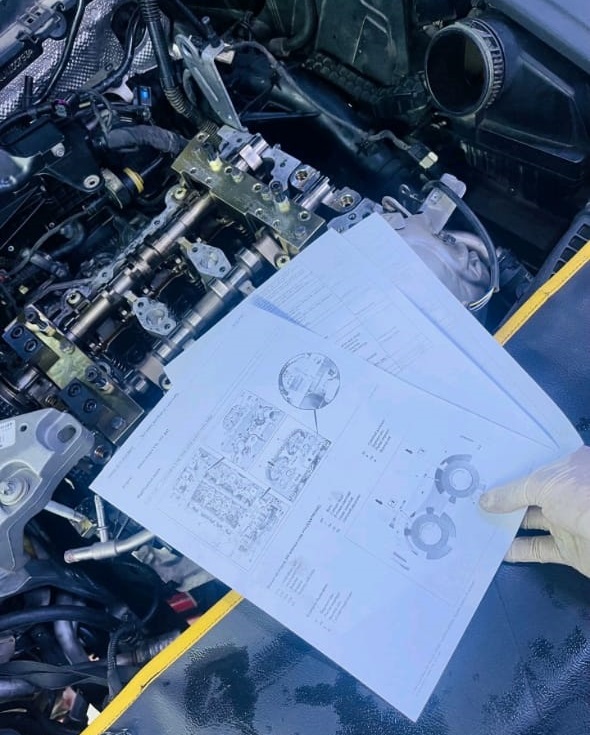

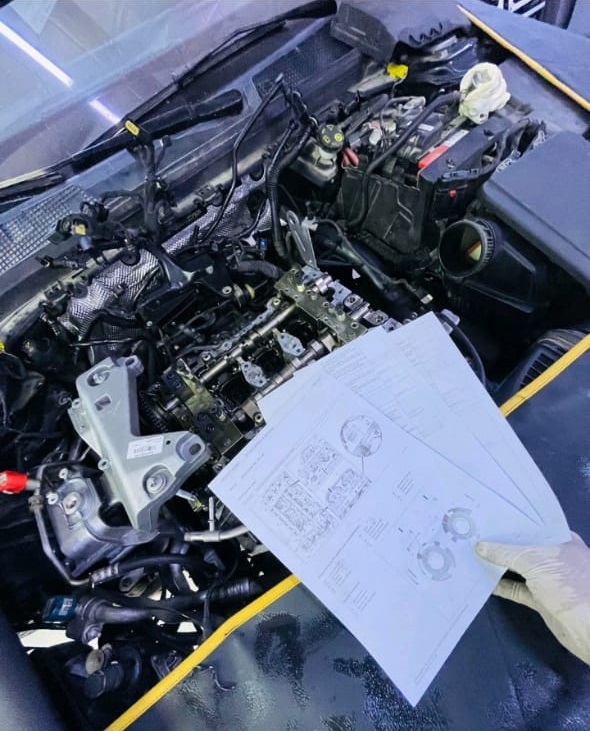

Reassembly & Setup:

- – Set timing using WIS alignment references.

- – Verified chain tension and timing marks.

- – Cleared DTCs and performed cam/idle adaptations.

Post-repair tests:

- – Crank → Immediate start

- – No DTCs returned

- – Stable cam actual vs. specified positions on live data

Quick Reference Tables

Symptoms → Likely Causes

| Symptom | Likely Cause |

|---|---|

| Cranks, won’t start | Cam/crank correlation off (timing/phaser) |

| DTCs for cam position | Sensor signal skewed by mechanical misalignment |

| Intermittent sync during crank | Sticking/failed cam phaser or worn sprocket |

What We Tested

| Test | Result | Meaning |

|---|---|---|

| Sensor power/ground | OK | Sensor powered; look at signal/mechanics |

| Signal waveform | Unstable | Correlation problem likely |

| Harness continuity | OK | Not a wiring fault |

| Mechanical timing | Off | Root cause confirmed |

Camshaft Adjusters (Phasers) : Fast Primer

- – Role: Advance/retard cam timing (VVT) for power, economy, emissions.

- – How: Hydraulic (oil-pressure) phaser controlled by ECU via solenoid; feedback via cam sensor.

- – Failure modes: Wear, internal sticking, oil sludge, solenoid faults → timing misalignment, no start, misfires.

Prevention:

- – Use MB-approved oil, change on time, keep oil passages clean; inspect/replace phaser if adaptation values drift.

Camshaft Position Sensor ; Location & Notes (General)

- – Typically on the cylinder head near the cam; varies by engine (front/side/rear).

- – A failed sensor can cause hard/no-start, but mechanical mis-timing can mimic sensor failure.

Takeaways

- – Don’t stop at a sensor DTC validate mechanical timing when the engine cranks but won’t start.

- – Power/ground OK + bad signal = suspect timing/phaser, not just the sensor.

- – Always finish with adaptations and a correlation check in live data.

Prevention & Maintenance

| Action | Why it Helps |

|---|---|

| Follow MB oil spec & intervals | Keeps VVT hydraulics clean and responsive |

| Inspect timing marks if correlation DTCs repeat | Catches early phaser/chain issues |

| Replace filters with OEM | Ensures correct oil flow/pressure to phasers |

| Record live data baselines | Early detection of drift in cam actual vs. specified |

Related Diagnostic Resource

If you’re facing similar starting problems, explore our full troubleshooting hub:

Mercedes No Start Issues: Causes, Fixes & Case Studies : a complete guide covering electrical, fuel, and ECU-related no-start scenarios across multiple Mercedes models.

FAQ

Q1: Why does the car crank but not start if the sensor has power?

Because the mechanical timing can be off so the ECU sees invalid cam/crank correlation and withholds start.

Q2: Can a bad camshaft adjuster alone cause a no-start?

Yes. A stuck or misindexed phaser can push timing far enough out to prevent combustion during crank.

Q3: Should I replace the cam sensor first?

Not before confirming timing alignment. Replace the sensor only if power/ground/signals remain faulty with verified timing.

Author Bio

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last update: October 2025

Leave a Reply