Table of Contents

Mercedes 7G‑Tronic (722.9) 7‑Speed Automatic: Guide, Common Faults & Maintenance

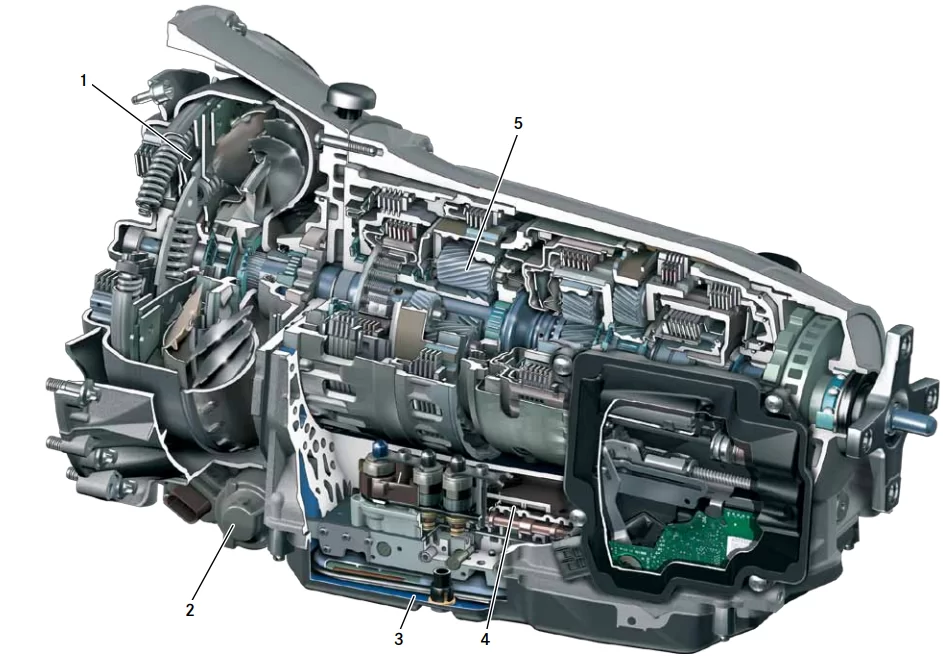

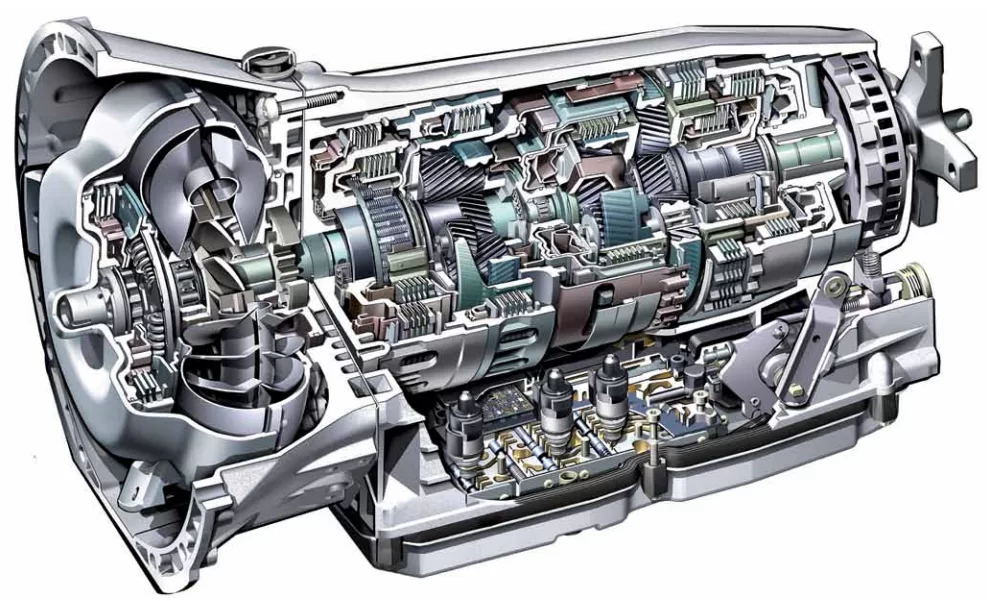

Introduced in 2003, the 7G‑Tronic is Mercedes’s first 7-speed automatic gearbox (model 722.9), widely used up to 2020. Known for smooth shifts, improved efficiency, and torque converter lock‑up across all gears, it powers a broad range of models from E‑Class to AMG variants.

Designed to deliver smoother shifts, quicker acceleration, and better fuel efficiency, the 7G TRONIC has played a crucial role in enhancing the overall performance of various Mercedes-Benz models.

Mercedes 7G TRONIC remains a cornerstone in the brand’s transmission lineup, known for its durability and refined driving characteristics. It allows for seamless gear changes and optimized power delivery, contributing to a more responsive and comfortable driving experience. Whether in luxury sedans, SUVs, or performance models, this transmission system has helped solidify Mercedes-Benz’s reputation for engineering excellence.

7G‑Tronic Specifications & Applications

| Feature | Details |

|---|---|

| Model | 722.9 (aka W7A700, NAG2) |

| Gears | 7 forward + 2 reverse |

| Introduced | 2003 (first in E500, S‑Class, C-Class, CL, SL) |

| Casing material | Magnesium alloy |

| Notable variants | AMG SpeedShift, MCT (manually shifted) |

Technical Specifications

Mercedes 7G Tronic Features

The Mercedes 7G Tronic transmission boasts a range of features that set it apart:

- – 7-speed automatic transmission: Offers a wide gear ratio spread, providing better acceleration and fuel efficiency.

- – Gear ratios and efficiency: Optimized for smooth transitions and minimal energy loss.

- – Compatibility with different engines: Suitable for a variety of Mercedes-Benz engines, from smaller inline-fours to powerful V8s.

7G Tronic vs 7G Tronic Plus

Key differences: The 7G Tronic Plus features enhanced torque converter lock-up, reduced friction, and improved software for smoother shifts.

Performance improvements: Better fuel economy and quicker response times.

Applications in various Mercedes models: Widely used across the Mercedes-Benz lineup, from the C-Class to the S-Class.

Performance and Efficiency

Driving Experience

The 7G Tronic transmission delivers a refined driving experience with:

- – Smoothness of gear shifts: Almost imperceptible changes between gears.

- – Response time: Quick adaptation to driving conditions, ensuring optimal performance.

- – Impact on acceleration and speed: Improved acceleration and consistent power delivery across all speeds.

Fuel Efficiency

- – Role in improving MPG: The 7G Tronic’s efficient gear ratios contribute to lower fuel consumption.

- – Eco-friendly features: Designed to minimize emissions and maximize fuel economy.

- – Real-world fuel economy comparisons: Owners report noticeable fuel savings compared to older transmission models.

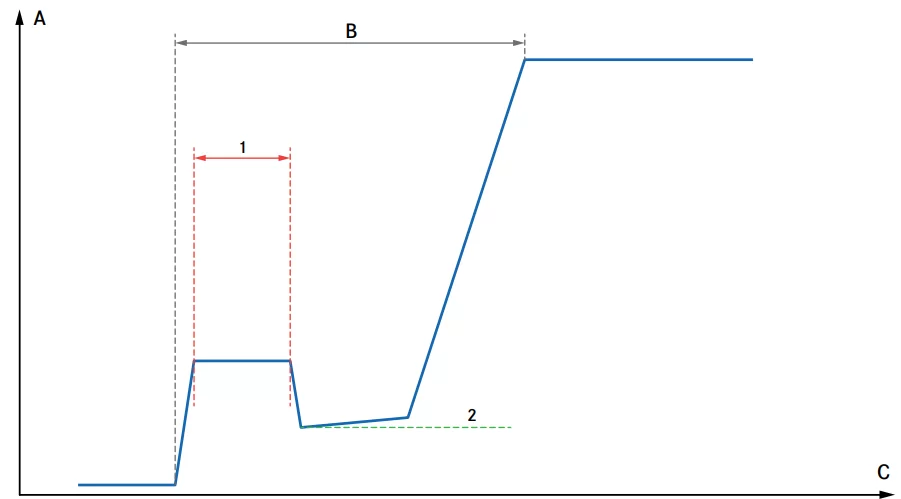

- 1. Filling Time

- 2. Application Pressure

A. Pressure

B. Gear Control

C. Time

Common Mercedes 7g tronic problems and Troubleshooting

Mercedes 7g tronic problems

Despite its advantages, the 7G Tronic transmission can encounter issues such as:

Why Is My Automatic Car Not Shifting Gears ?

Car Starts But Won’t Move When In Drive

Delayed Shifting When Accelerating

Car Jerks When Shifting From Park to Drive : Find Solution Here

Engine Doesn’t Start and Gear Shift Light Not Working : 100% Solution

P2716 Transmission Shifting Problems: Solution Here

| Issue | Symptoms | Diagnosis & Fix |

|---|---|---|

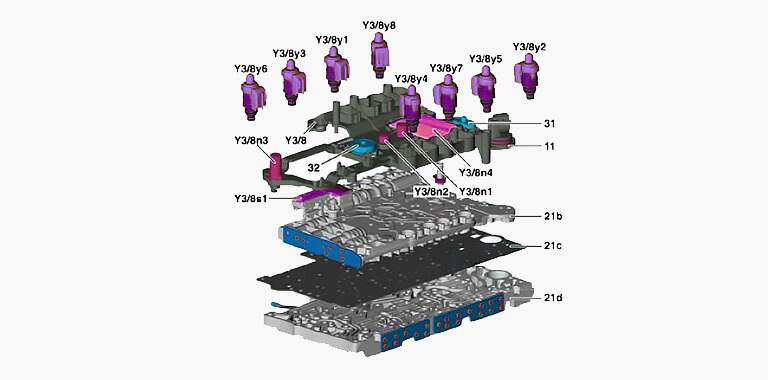

| Conductor plate / TCM failure | Limp mode; stuck in gear; erratic shifting | Replace/rebuild mechatronic ECU and valve body; requires coding |

| Solenoid/valve faults (TCC/KÜB) | Rough shifts, delayed gear changes | Replace faulty solenoids/wiring in valve body |

| Speed sensor errors (VGS) | Fault codes P0717/18 (turbine speed); P2767/68 | Inspect/replace sensors; repair wiring or replace ECU |

| Cold‑weather shifting jerkiness | Harsh 2→3 shifts until warm | Normal adaptation ensure fluid is within spec |

| Valve‑body wear / conductor plate delamination | Gear selection issues, limp mode | Remove valve body; rebuild conductor plate to prevent failure |

| Limp‑home mode due to TCM internal fault | Transmission locked in 2nd or 6th gear | Scan fault codes, rebuild or replace TCM module |

How do I know if my gearbox has gone?

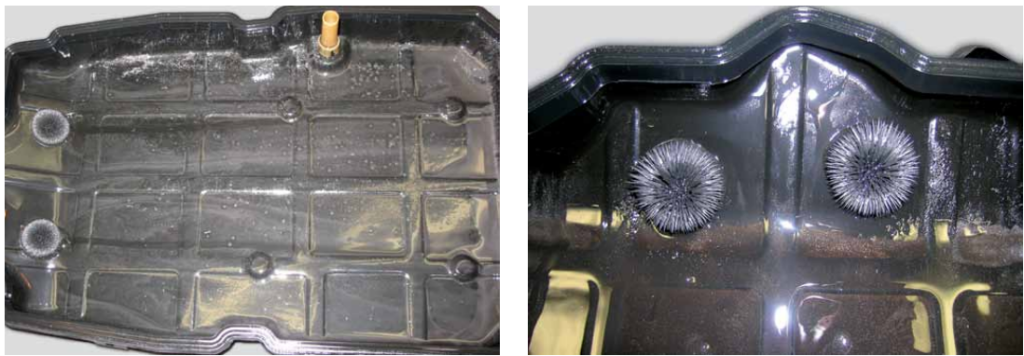

In a gearbox that has only operated for a few kilometers, tear-off chips may have already accumulated in the oil pan in the form of metallic particles (resembling flakes). These particles come from the metal parts inside the gearbox that move against each other, such as the disk carriers in which the disks lightly strike during operation.

These particles accumulate in the oil pan and do not pose a danger to the electro-hydraulic control system, as the oil filter is there to remove them.

In the event of a claim, it is important to differentiate between these flakes and elongated chips, as well as between a “normal” pattern of chips and an excessive accumulation of chips. Although the chips are also removed by the filter, they are caused by damage to a component and can therefore be related to the claim.

If elongated chips (3-10 mm in length) are found, their origin must be determined, and defective components replaced if necessary. If component replacement is not economical, a standard gearbox exchange may be required.

A standard gearbox exchange is currently recommended for the following damages:

- – The oil pump has bitten into the housing

- – Defective rear planetary gear train

- – Torque converter lockup clutch or other components in the converter worn (many chips in the gearbox oil pan without detectable defects in the gearbox)

In case of heavy contamination, it is also recommended to replace the cooler.

Flushing the cooler is not possible as the thermostat only opens at an oil temperature of about 80°C.

The following figures show examples of gearboxes with visible mechanical damage and gearboxes where damage cannot be concluded based on the figures. Damages occurring without chip formation are, of course, not excluded.

Maintenance & Prevention

To keep the 7G Tronic in top condition:

1. Recommended service intervals: Follow the manufacturer’s guidelines for transmission service.

2. Fluid changes and checks: Regularly replace transmission fluid and filter.

3. Common wear and tear parts: Monitor and replace components like seals and gaskets as needed.

Oil Filter and Oil Pan

For the automatic gearbox, there have been four different oil filters and oil pans available up until now. Currently, two oil filters and oil pans are in use.

Although the outdated components are still in circulation, they are replaced by their corresponding successors in the event of a claim. The old components can no longer be ordered. The current oil filters and oil pans are shown below with their references and identification criteria.

How do you know if your transmission fluid is low on a Mercedes?

Measuring and Adjusting the Oil Level for 7G TRONIC

The oil level should always be checked when there are signs of possible underfilling. These include:

- – Visible leaks

- – After work on the gearbox cooling system

- – In case of complaints appearing primarily in very cold conditions

- – In case of complaints appearing on steep inclines/descents and/or during fast cornering

A general oil level check is not necessary for complaints regarding gear shifting quality.

The method for filling the gearbox oil depends on the vehicle version. A distinction is made between vehicles with or without an additional gearbox oil cooler:

- – Without additional gearbox oil cooler

- – With additional gearbox oil cooler

When the oil drain screw is unscrewed at 45°C on gearboxes with an oblique gearbox oil pan, at least a small amount of oil (the oil that was in the tube) will flow out.

If no additional oil comes out after this small amount, it only means that the oil level is below the upper edge of the tube. If the oil level is only a few millimeters below the edge, the oil level is still within tolerance.

Therefore, it is not possible to assess the oil level by unscrewing the drain screw. If a low oil level is suspected, 0.5-1 liters of gearbox oil should be added and the excess oil drained again until only a small amount flows out. Only after collecting and measuring this excess oil can a judgment be made about the missing amount.

The gearbox oil level is then adjusted to the middle of the tolerance range. If the oil level was previously at the “in order” (“i.O.”) mark on the drawing, it is possible that only 0.1-0.2 liters of gearbox oil were added.

In this case, the gearbox was not underfilled before, even though no oil flowed out. If more than 0.3 liters of oil are needed to reach the state shown in figure b, the oil level was outside the tolerance.

For more details in the next link ; How To Check Automatic Transmission Oil

DIY vs Professional Work

| Component | DIY Possible | Professional Recommended |

|---|---|---|

| Fluid & filter change | Yes | — |

| Conductor plate rebuild | Skilled with parts may attempt | Specialist tools and coding needed |

| Replace solenoids/wires | Possible with guides | Proper assembly and test needed |

| TCM replacement + coding | Not recommended | Dealer programming required |

| Valve body service | Not recommended | Manufacturer tooling required |

Upgrades and Modifications

Aftermarket Options

Enhance your 7G Tronic with:

- – Performance upgrades: Upgraded torque converters and performance clutches.

- – Software tuning: Custom transmission control unit (TCU) programming for improved performance.

- – Enhanced cooling systems: Additional cooling for high-performance applications.

Compatibility and Considerations

- – Ensuring compatibility with existing systems: Verify that upgrades are compatible with your vehicle’s existing systems.

- – Potential impact on warranty: Aftermarket modifications may void your warranty.

- – Pros and cons of modifications: Balance the benefits of improved performance against potential drawbacks.

User Reviews and Testimonials

Owner Experiences

Many Mercedes-Benz owners have shared their experiences with the 7G Tronic:

- – Positive feedback: Praised for its smooth operation and reliability.

- – Common complaints: Some report issues with hard shifts and transmission slipping.

- – Long-term reliability: Generally considered durable with proper maintenance.

Expert Opinions

- – Automotive reviews: Experts commend the 7G Tronic for its performance and efficiency.

- – Comparisons with other transmissions: Often compared favorably against competitors’ transmissions.

- – Market reputation: Maintains a strong reputation in the luxury automotive market.

Conclusion

Summary of Key Points

- – Benefits of the Mercedes 7G Tronic: Smooth shifts, improved fuel efficiency, and enhanced driving experience.

- – Common issues and how to address them: Regular maintenance and timely troubleshooting can prevent major problems.

- – Overall reliability and user satisfaction: Highly regarded by both owners and experts.

Final Thoughts

The Mercedes 7G Tronic remains a popular choice for its blend of performance, efficiency, and reliability. As Mercedes-Benz continues to innovate, the 7G Tronic sets a high standard for automatic transmissions.

Frequently Asked Questions

What is a conductor plate failure?

It’s a worn or delaminated valve-body circuit layer causing erratic shifting, limp-mode, and gear selection issues; typically requires rebuild.

When does limp mode activate?

If the ECU detects hydraulic or electrical transmission faults, it locks into 2nd or 6th gear until repaired.

Can I rebuild the TCM myself?

No, requires professional tools, correct valve-body assembly, and coding on VIN. DIY splicing risks errors.

How important is transmission fluid maintenance?

Vital old or contaminated fluid accelerates wear on solenoids, valve body, and mechatronics.

— Salim, Mercedes Expert

Independent specialist in Mercedes-Benz diagnostics, CAN Bus analysis, troubleshooting case studies, and EV systems.

Leave a Reply