Table of Contents

AIRMATIC Mercedes Not Working: Case Study of a Mercedes GL Repair

Mercedes-Benz vehicles are known worldwide for their luxury, comfort, and advanced technology. One key system responsible for the smooth driving experience in larger models such as the Mercedes GL X166 is the AIRMATIC air suspension.

This adaptive system automatically adjusts ride height and damping to provide stability and comfort under varying driving conditions.

However, when an AIRMATIC malfunction occurs, it can significantly affect handling, ride quality, and safety. In this case study, we examine a Mercedes GL X166 that arrived at the workshop with a faulty AIRMATIC suspension, focusing on the diagnostic process, repair steps, and final resolution.

Understanding the AIRMATIC System

What is AIRMATIC?

AIRMATIC is Mercedes-Benz’s advanced air suspension system, designed to replace conventional steel springs with air springs. Its main components include:

- – Air compressor : generates and maintains air pressure.

- – Air springs (airbags) : support vehicle weight and absorb shocks.

- – Shock absorbers with adaptive damping : adjust firmness in real time.

- – Valve unit : distributes air pressure to each wheel.

- – Sensors and control module : monitor ride height and adjust settings.

Common Issues

Like any sophisticated system, AIRMATIC can fail due to:

- – Air leaks (in springs, lines, or fittings).

- – Faulty compressors that can no longer build sufficient pressure.

- – Malfunctioning valve blocks that disrupt air distribution.

- – Sensor or wiring faults that send incorrect ride height data.

When these issues occur, drivers may see warning lights, experience sagging on one side, or feel rougher handling.

Case Study Background

- Vehicle: Mercedes-Benz GL X166

- Owner Complaint: The front left side of the SUV was sitting noticeably lower than the right side.

This visible sagging suggested that the AIRMATIC suspension was not functioning correctly.

Diagnostic Process

Step 1: Initial Inspection

The technician began with a visual inspection, checking for external leaks, damaged lines, or collapsed air springs. Although no obvious leaks were visible, the uneven ride height indicated an internal fault.

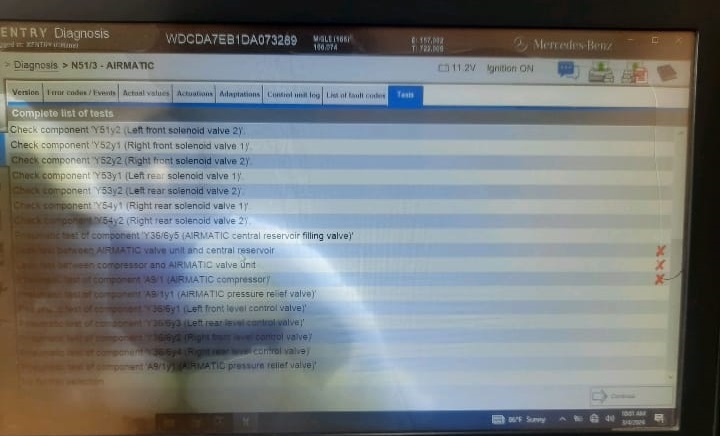

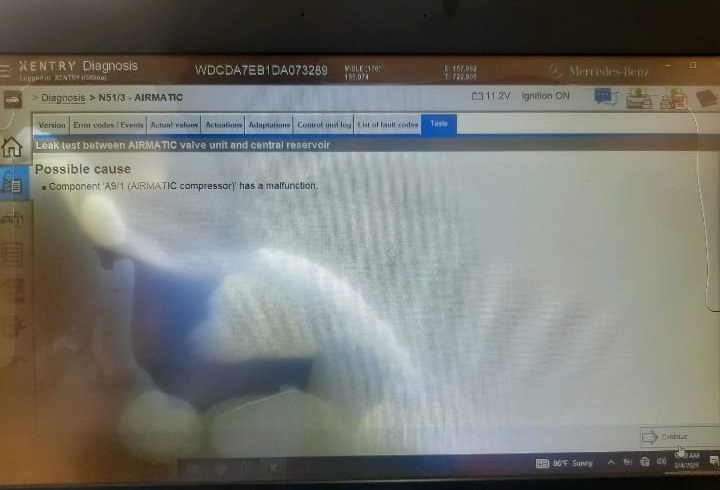

Step 2: Diagnostic Scan with Xentry

Using Mercedes-Benz Xentry Diagnosis, the suspension system was scanned. Fault codes were retrieved that pointed to circuit pressure issues.

Step 3: Pressure Check

Live data from the system showed imbalanced pressure values, consistent with the uneven ride height complaint.

Step 4: Compressor Test

The AIRMATIC compressor was tested for output. Results showed low compression, confirming that the compressor was no longer functioning properly.

Step 5: Valve Unit Test

The valve unit was also tested. It showed signs of malfunction, contributing to the pressure imbalance and the system’s inability to maintain ride height.

Repair Process

Step 1: Identifying Parts to Replace

Based on the diagnostics, three components were identified as faulty:

- 1. AIRMATIC compressor : failing to generate pressure.

- 2. Relay : often replaced alongside the compressor to prevent repeat failures.

- 3. Valve unit : malfunctioning and disrupting pressure control.

Step 2: Replacement Procedure

- – Removed the old compressor and installed a new OEM unit.

- – Replaced the compressor relay to ensure reliable operation.

- – Installed a new valve unit and verified proper connections.

- – Ensured all fittings were secure and leak-free.

Step 3: Calibration & Reset

- – Cleared all stored fault codes using Xentry.

- – Recalibrated suspension ride height values.

- – Reactivated the AIRMATIC system for testing.

Post-Repair Testing

System Retest

After repairs, pressure values returned to the correct range. The vehicle’s ride height was level, with no sagging detected.

Final Test Drive

A road test confirmed that:

- – The vehicle handled normally.

- – Ride quality was smooth and adaptive.

- – No warning messages reappeared.

Symptom -> Cause -> Fix Table

| Symptom | Likely Cause | Repair Solution |

|---|---|---|

| Front left suspension too low | Faulty compressor or leaking air spring | Replace compressor or air spring, recalibrate system |

| AIRMATIC warning light on dashboard | Circuit pressure fault, valve unit issue | Diagnose with Xentry, replace defective valve block |

| Compressor running constantly | Leak in lines or malfunctioning valve | Repair leaks, replace faulty valve or relay |

| Vehicle leaning to one side | Air line or strut leak | Inspect connections, replace damaged strut or line |

| Suspension not responding to mode changes | Control module or sensor fault | Scan for fault codes, replace or reprogram ECU |

Explore More Mercedes Suspension Issues

For a deeper dive into suspension problems such as uneven ride height, AIRMATIC malfunctions, “Stop Vehicle Too Low” warnings, and vibration faults, visit our hub: Mercedes-Benz Suspension Issues – Symptoms, Causes & Fixes. There you’ll find grouped case studies, step-by-step diagnostics, symptom, cause, fix tables, and preventive tips to keep your Mercedes riding smoothly.

Common Symptoms of AIRMATIC Not Working in Mercedes

- – Vehicle sagging on one side or corner.

- – Dashboard warning: “AIRMATIC malfunction.”

- – Compressor running excessively or making loud noises.

- – Rough, unstable, or bouncy ride.

- – Suspension not rising or lowering when adjusting modes.

FAQs: Airmatic Mercedes Not Working

Q: Can I drive my Mercedes if the AIRMATIC suspension is not working?

A: It’s possible but not recommended. Uneven ride height reduces handling stability, increases braking distance, and can cause tire wear.

Q: How much does it cost to repair AIRMATIC suspension?

A: Costs vary. A compressor replacement typically costs $1,000–$1,500, while valve blocks and struts can add to the expense.

Q: Should I replace the relay with the compressor?

A: Yes. Relays often fail when compressors wear out. Replacing both prevents repeated breakdowns.

Q: How long does a Mercedes AIRMATIC compressor last?

A: On average, 6–10 years or 80,000–100,000 miles, depending on usage and maintenance.

Q: Can leaks cause compressor failure?

A: Yes. Undetected leaks force the compressor to run continuously, leading to overheating and premature failure.

Conclusion

This case study of a Mercedes GL X166 with a faulty AIRMATIC suspension shows how proper diagnostics and targeted repairs restore the luxury ride quality Mercedes is known for.

The fault was traced to a failing compressor, defective relay, and malfunctioning valve unit. By replacing these components, recalibrating the system, and performing a thorough test drive, the suspension was fully restored.

For Mercedes owners, the lesson is clear: never ignore suspension warnings or visible sagging. With early diagnosis and professional repairs, you can avoid costly failures and keep your Mercedes driving smoothly for years to come.

Author

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last Updated: September 2025

Leave a Reply