Table of Contents

Mercedes Key Not Working Ignition; Real Case Study & Expert Diagnosis (S350 W222)

When your Mercedes key doesn’t work in the ignition no dashboard lights, no multimedia response, and complete electrical silence it’s more than an inconvenience.

This type of failure usually points to a communication or power issue within the vehicle’s electronic control network (CAN Bus).

This case study explores a Mercedes-Benz S350 (W222) that presented exactly this condition and the diagnostic process that led to identifying a CAN Bus communication fault caused by water ingress.

For a deeper look into how SAM, ECU, and CAN Bus faults cause ignition, lighting, and module failures across Mercedes models, visit our master guide:

Mercedes Electrical Problems: Fix SAM, ECU & CAN Bus Faults

Vehicle Information

– Model: Mercedes-Benz S-Class W222 (S350)

– System: Keyless-Go ignition (FBS4 security platform)

– Engine: OM642

– Complaint: Key not recognized, ignition dead, no dashboard display, and no multimedia power.

Initial Observation

The customer reported that the vehicle suddenly failed to start after being parked overnight.

When pressing the Start/Stop button, nothing illuminated on the cluster or COMAND screen not even accessory mode.

A visual check confirmed that the main battery voltage appeared normal (≈12.5 V), and both key fobs transmitted normally under RF testing.

This immediately suggested a network-level fault rather than a key coding or immobilizer failure.

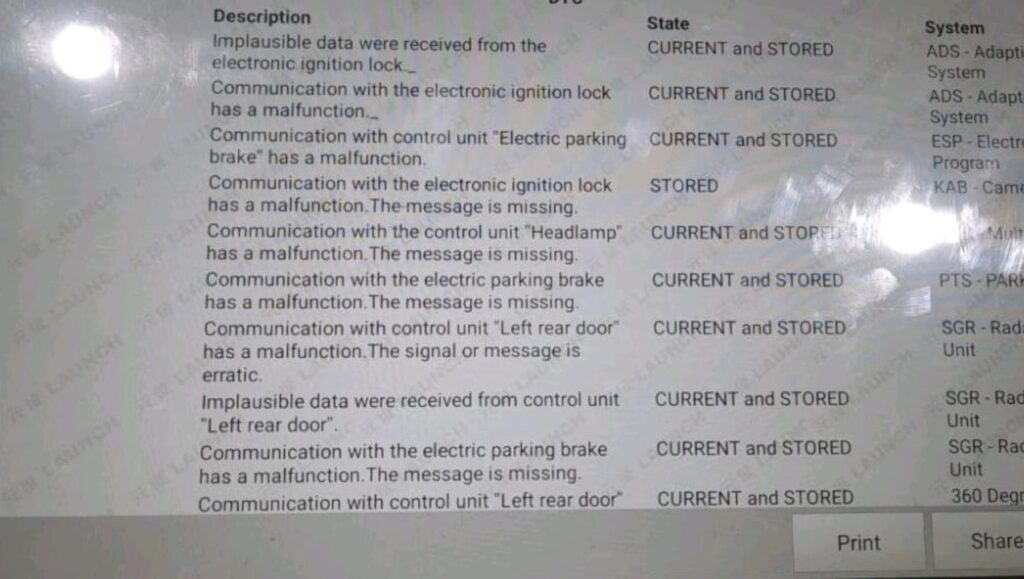

Diagnostic Overview; CAN Communication Failure

The technician connected diagnostic tool and attempted to communicate with the Electronic Ignition Switch (EIS/EZS) and related modules.

Result:

- – Multiple modules were not reachable via CAN.

- – EIS, Instrument Cluster (IC), and Front SAM failed to respond.

- – Diagnostic tool displayed “No Communication” with the interior CAN Bus.

At this point, the failure was localized to a CAN Bus short or open circuit preventing communication between the ignition system and other control units.

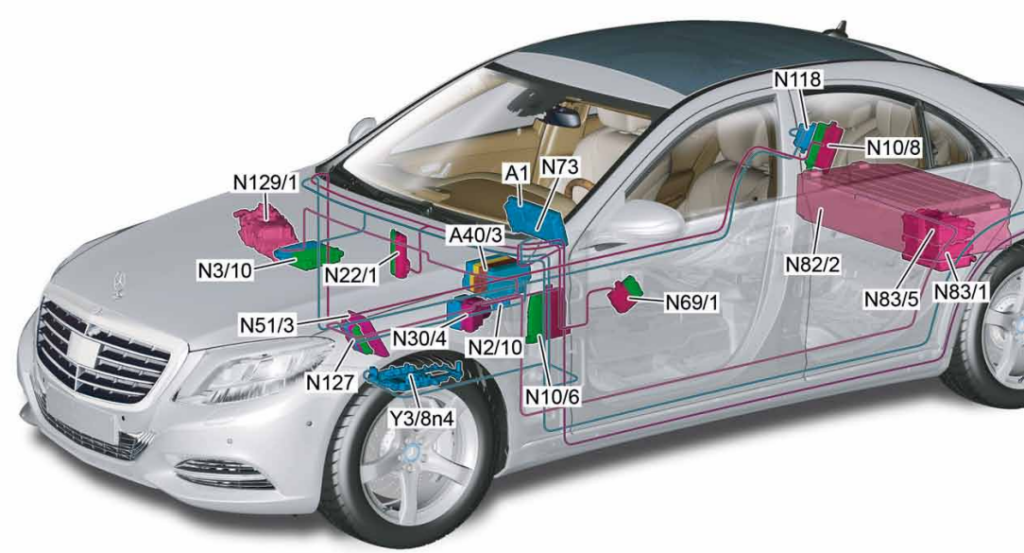

Network Structure Review

The W222 uses a multi-branch CAN/LIN architecture, where the following modules must communicate for ignition activation:

| Subsystem | Network | Function |

|---|---|---|

| EIS/EZS | Interior CAN | Key authorization, ignition logic |

| Front SAM | CAN Gateway | Power distribution and wake-up control |

| Instrument Cluster | Interior CAN | System status display |

| Powertrain ECU (ME/CRD) | Drive CAN | Start authorization handshake |

A failure in any section of the CAN backbone or its connectors can isolate these units, leading to a “dead” ignition system.

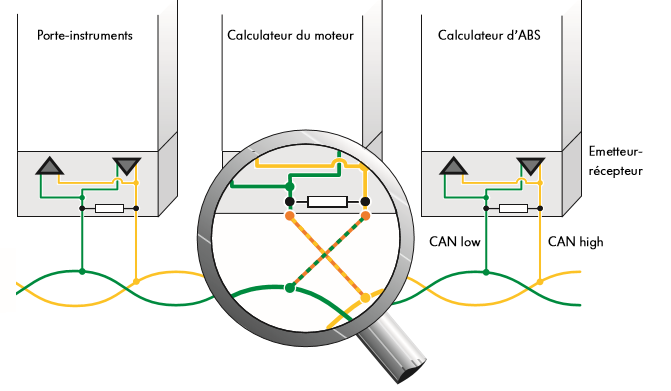

Detailed Testing

The technician began by checking CAN Bus integrity at several points:

| Test | Method | Expected Value | Result |

|---|---|---|---|

| CAN High/Low resistance | Multimeter, ignition OFF | ≈ 60 Ω | Open circuit detected |

| Voltage check (ignition ON) | CAN High ≈ 2.5–3.5 V, CAN Low ≈ 1.5–2.5 V | Unstable readings | |

| Ground continuity | < 0.1 Ω | OK | |

| Power feed at Front SAM | 12 V constant | OK |

These findings pointed toward a physical disruption or short circuit on the Interior CAN Bus wiring harness.

Root Cause Discovery; Water Ingress in Harness

Upon visual inspection, the technician removed the front passenger footwell trim to access the main CAN junction distributor (the star connector under the carpet).

Findings:

- – Moisture traces and green oxidation on the CAN distributor pins.

- – Water droplets on nearby harness insulation.

- – Corrosion bridging CAN High and CAN Low, effectively shorting communication.

The moisture source was later traced to a clogged windshield drain, which had allowed water to leak into the wiring channel below the carpet.

Corrective Actions

| Step | Description |

|---|---|

| Drying & Cleaning | The entire affected area was dried using warm air circulation. |

| Harness Repair | Corroded terminals in the CAN distributor were replaced and sealed. |

| Connector Protection | Electrical contact cleaner + dielectric grease applied. |

| Drainage Restoration | Clogged windshield drain and cowl area cleaned to prevent recurrence. |

| Network Validation | Rechecked CAN resistance (60.2 Ω confirmed stable). |

| Control Unit Reinitialization | XENTRY network scan repeated communication restored to all modules. |

Validation Results

| Component | Before | After |

|---|---|---|

| Ignition Response | No power | Full accessory and ON stages restored |

| Dashboard | Dark | Fully operational |

| COMAND screen | Off | Booting normally |

| CAN Bus reading | Open circuit | 60 Ω nominal |

| Stored DTCs | Multiple “No Communication” | Cleared successfully |

After reassembling the interior trim, the technician cycled ignition multiple times and performed a start authorization test.

The engine started normally, and all communication paths remained stable after a 15-minute soak test.

Root Cause Summary

| Category | Description |

|---|---|

| Primary Cause | Water intrusion in CAN Bus harness (front passenger footwell). |

| Secondary Impact | Short circuit in star connector causing loss of ignition communication. |

| System Affected | Interior CAN (EIS/EZS, SAM, Cluster). |

| Resolution | Harness repair, connector cleaning, drainage maintenance. |

Technician Takeaways

- – A dead ignition with no dashboard lights is often a CAN Bus communication failure, not necessarily a key or EIS fault.

- – Always inspect CAN junctions under carpets for moisture common after heavy rain or washing.

- – Measure resistance at the OBD or CAN splice before suspecting modules.

- – Maintaining clean drainage channels (sunroof, windshield) can prevent future electrical failures.

Related Diagnostic Resource

If your Mercedes exhibits power loss, ignition silence, or “No Communication” DTCs across multiple modules, see our advanced guide:

Mercedes Electrical Problems: Fix SAM, ECU & CAN Bus Faults

A complete reference for diagnosing module communication issues, power-feed losses, and ground faults in Mercedes electrical networks.

Conclusion

This Mercedes-Benz S350 W222 “Key Not Working Ignition” case illustrates how minor water ingress can cause major electrical paralysis through CAN Bus disruption.

By methodically testing network integrity, identifying harness contamination, and repairing the corroded junction, the technician restored full system communication without replacing expensive modules.

This approach not only saved the customer time and cost but also highlights the importance of electrical network diagnostics in modern Mercedes vehicles.

Author Bio

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last update: November 2025

Leave a Reply