Table of Contents

Automatic Car Not Shifting Gears (Mercedes E-Class 7G-Tronic) — Case Study

When an automatic won’t shift or won’t move even as revs rise/fall, the fault can be hydraulic, electrical, or mechanical. This case study covers a Mercedes E-Class with 7G TRONIC (722.9) that intermittently failed to move and later presented no upshifts.

The root cause was a contaminated/“wet” clutch solenoid and a dirty hydraulic block (valve body) leading to unstable operation.

Vehicle & Complaint (Snapshot)

| Item | Detail |

|---|---|

| Model | Mercedes-Benz E-Class (7G-Tronic / 722.9) |

| Primary symptom | Revs change but car won’t move or refuses to upshift (“stuck in 1st/limp”) |

| Initial finding | Clutch solenoid “wet” and contaminated, hydraulic block sludged |

| Definitive fix | Remove valve body, clean all solenoids/passages, replace damaged solenoids, renew ATF/filter, level set at temp, verification drive |

How These Failures Cause “No Shift / No Drive”

The 7G-Tronic uses electro-hydraulic solenoids inside a valve body to route ATF pressure to clutch packs. If a solenoid is wet with contaminated fluid, its electromagnetic response and spool movement become erratic; the valve body’s fine passages can also varnish/plug, so commanded pressure never reaches the clutch.

The TCU then detects implausible speed/pressure signals and drops to failsafe (limp) or refuses engagement.

Typical sources of contamination/wet solenoid readings:

- – ATF degradation (overdue service, overheating)

- – Fluid wicking through the 13-pin connector sleeve, affecting electrical integrity

- – Moisture/coolant intrusion from a failing cooler (less common, but critical to rule out)

Symptom → Likely Cause → First Checks

| Symptom | Likely Cause(s) | First Checks |

|---|---|---|

| Revs change but car won’t move | Stuck clutch solenoid; clogged valve body; severe ATF breakdown | ATF level/condition, scan TCM for solenoid/pressure DTCs |

| Harsh/late shifts, flare | Sticky solenoids; low/dirty ATF; adaptations lost | Pan debris; connector sleeve leaks; run adaptations after repairs |

| Stuck in one gear (limp) | Electrical fault in mechatronics; sensor mismatch | Battery/voltage stability; DTCs; live data speeds/pressures |

| Delayed D/R engagement | Low ATF; restricted passages; internal leakage | Level at temperature; filter condition; pressure tests if applicable |

Repair Process (Step-by-Step)

1. Secure & prepare

- – Connect battery maintainer.

- – Lift vehicle safely; protect undertrays.

2. Drain ATF & remove pan/filter

- – Capture fluid sample for condition check.

- – Note debris on magnet (helps forecast wear).

3. Remove valve body (hydraulic block)

- – Follow Mercedes WIS/ASRA torque/sequence.

- – Disconnect 13-pin connector carefully to avoid pin damage.

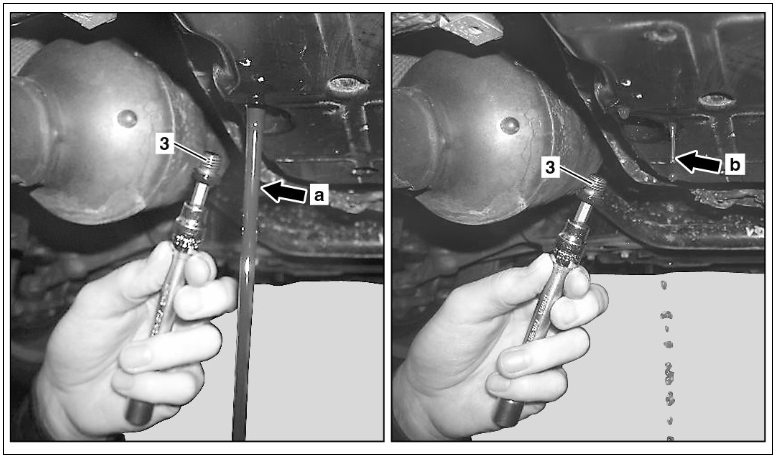

4. Solenoid service & testing

- – Extract clutch/shift solenoids; clean with fresh, correct-spec ATF.

- – Measure coil resistance against spec; any out-of-range gets replaced.

- – Verify mechanical “click” and smooth spool motion during bench actuation.

5. Hydraulic block cleaning

- – Flush all valve body passages with fresh ATF; ensure no sludge/varnish remains.

6. Reassembly

- – Refit serviced/replacement solenoids; torque per spec.

- – Install new filter and pan gasket; replace connector sleeve/O-rings if weeping.

- – Refill with MB-approved ATF; set level at temperature using the correct procedure.

7. Adaptations & verification

- – Clear DTCs; run standstill/running adaptations (preconditions: no DTCs, correct ATF temp, tire pressures in spec).

- – Road test: city + highway; monitor turbine/internal/output speeds, gear target vs actual, TCC slip.

Result: Vehicle regained normal drive and upshifts. No return of codes; engagement smooth, no flare or bang.

Parts & Operations

| Item | Action | Why |

|---|---|---|

| Solenoids (faulty units) | Replace | Out-of-spec resistance/actuation |

| All solenoids & valve body | Clean | Remove varnish/sludge restricting flow |

| ATF filter & pan gasket | Renew | Restore filtration and sealing |

| ATF (correct MB spec) | Replace | New fluid for stable pressure/temperature |

| 13-pin connector sleeve | Inspect/replace | Prevent fluid wicking/corrosion |

| Adaptations | Perform | Relearn clutch fill/overlap timing |

Explore More Mercedes Transmission Issues

For a deeper dive into gearbox problems slipping into Neutral, delayed/harsh shifts, “Not in P” warnings, and hybrid faults visit our hub: Mercedes Transmission Issues – Causes and Fixes. You’ll find grouped case studies, step-by-step diagnostics, symptom–cause–fix tables, and prevention tips to resolve shifting issues quickly and confidently.

Time & Cost (Indicative)

| Operation | Typical Time | Notes |

|---|---|---|

| Diagnosis & live-data logging | 1.0–1.5 h | Includes voltage checks |

| Pan/Filter/ATF service | 0.8–1.2 h | Temp-based level set |

| Valve body R&R + solenoid service | 3.0–5.0 h | Access varies by model |

| Adaptations + validation drive | 0.5–1.0 h | Preconditions critical |

Parts and labor vary by region; replacing multiple solenoids increases cost.

Live-Data Targets (What “Healthy” Looks Like)

| Parameter | Healthy Behavior | Red Flags |

|---|---|---|

| Turbine vs engine speed | Track proportionally at launch | Turbine stays 0 or erratic in gear |

| Gear target vs actual | Small, consistent delay | Frequent mismatch/forced downshifts |

| PRV/solenoid current profiles | Stable, repeatable | Dropouts/spikes with same load |

| TCC slip (cruise) | Low/steady | High, wandering slip values |

Troubleshooting Table: “Automatic Not Shifting”

| Symptom | Likely Cause | First Action |

|---|---|---|

| No movement in D/R | Stuck clutch solenoid; clogged valve body; very low ATF | Check level; pan down; solenoid/valve body service |

| Stuck in 2nd/3rd (limp) | Electrical fault in mechatronics; sensor mismatch | Scan TCM; verify connector sleeve; voltage stability |

| Delayed D/R engagement | Low/dirty ATF; clogged filter | ATF & filter service; level at temp |

| Harsh 1–2 or 2–3 | Sticky solenoid; adaptations lost | Solenoid clean/replace; run adaptations |

| Intermittent only when hot | ATF breakdown/overheat | ATF condition; cooler/thermostat check |

Prevention & Maintenance

- – Service ATF & filter at sensible intervals (many specialists: 60–80k km / 4–5 years), even if “lifetime.”

- – Inspect the 13-pin connector sleeve for leaks at every service.

- – Keep battery/charging healthy low voltage corrupts solenoid control and adaptations.

- – Address minor harshness or delays early; they are warnings, not quirks.

- – If a cooler is suspected, test for glycol (milky ATF) and repair immediately.

Learn about the transmission oil control in the following article How to check automatic transmission oil

FAQs: Automatic Car Not Shifting Gears

1) Is a “wet solenoid” normal?

Solenoids live in ATF, but “wet” here refers to contaminated fluid or wicked fluid at the connector affecting electrical integrity. Either condition demands service (clean/replace, sleeve inspection).

2) Will a fluid change alone fix no-shift?

Sometimes ATF/filter service restores marginal operation, but stuck or damaged solenoids and a sludged valve body require removal, cleaning, and often solenoid replacement.

3) Can I keep driving if the car won’t upshift?

Not recommended. Limp or no-drive conditions overheat ATF and can damage clutches. Diagnose and repair promptly.

4) Do I need adaptations after repair?

Yes. After any valve body/solenoid work or battery loss, perform standstill and running adaptations to relearn clutch fills/overlaps.

5) What else can cause similar symptoms?

A failing torque converter, internal clutch/band wear, or speed/pressure sensor faults can mimic solenoid problems. Use live data and the pan/valve body inspection to distinguish.

6) How can I tell if coolant entered the transmission?

ATF appears milky/pink and may smell sweet. If suspected, stop driving, replace the failed cooler, and flush thoroughly.

7) Is this a full transmission rebuild situation?

Usually not. Most “no shift / won’t move” complaints from solenoid/valve-body causes resolve with cleaning, selective solenoid replacement, fresh ATF/filter, and adaptations.

Conclusion

In this E-Class 7G-Tronic, the automatic wouldn’t shift/drive because of a contaminated clutch solenoid and dirty valve body. A disciplined scan → pan → valve body & solenoid service → ATF/filter → adaptations → verify sequence restored factory-smooth shifting—without a gearbox rebuild. Address symptoms early and follow the procedure above to fix it once, correctly.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: September 2025

Leave a Reply