Table of Contents

Cannot Start Engine See Owner’s Manual: Mercedes-Benz C-Class W205 EQ Boost Case Study

If your Mercedes-Benz displays “Cannot Start Engine – See Owner’s Manual” on the dashboard, it can be alarming especially on newer EQ Boost or Mild Hybrid models.

This message often indicates a communication or voltage issue within the 48-volt hybrid system, which powers key components like the starter alternator.

In this detailed case study, we explore how technicians diagnosed and resolved this problem in a Mercedes-Benz C-Class W205 EQ Boost equipped with the M264 Engine.

Vehicle Overview

| Model | Mercedes-Benz C-Class W205 EQ Boost (Mild Hybrid) |

|---|---|

| Engine | M264 2.0L Turbocharged (EQ Boost system) |

| Complaint | “Cannot Start Engine See Owner’s Manual” message; engine won’t start |

| Previous Work | Starter alternator replaced by external workshop, issue persisted |

Customer Complaint

The customer reported that upon pressing the Start/Stop button, the engine failed to start, accompanied by the dashboard message: “Cannot Start Engine – See Owner’s Manual.”

Before arriving at the dealership, the vehicle had been taken to an independent workshop where the starter alternator (Integrated Starter Generator – ISG) was replaced.

Despite the replacement, the warning persisted, and the vehicle remained unresponsive.

Step 1: Initial Diagnostic Approach

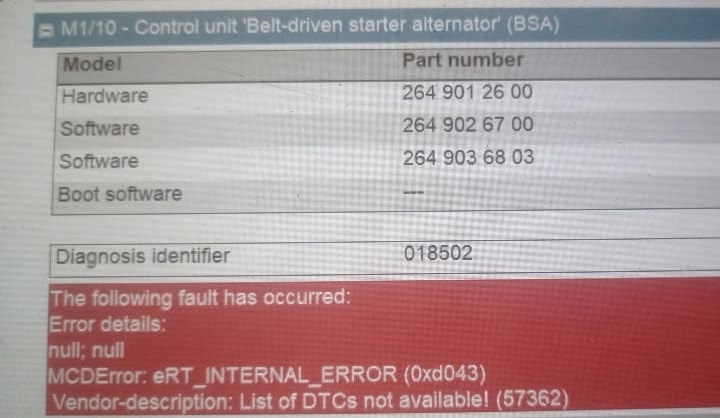

Upon arrival at the dealership, the vehicle was connected to the Mercedes-Benz XENTRY diagnostic system for a full scan.

Initial findings:

- – Starter alternator unresponsive

- – No communication with the 48-volt battery system

- – Several modules showing “offline” status within the drivetrain CAN network

Because the EQ Boost system relies on the 48V network for cranking and regenerative functions, a communication loss can completely disable the start sequence.

Step 2: Understanding the 48V EQ Boost System

Before proceeding with repairs, it’s vital to understand how the EQ Boost mild hybrid system operates:

| Component | Function |

|---|---|

| 48V Lithium-Ion Battery | Powers the Integrated Starter Generator (ISG) and electric compressor |

| Starter Alternator (ISG) | Acts as both starter and generator for the combustion engine |

| DC/DC Converter | Converts 48V to 12V to power traditional systems |

| CAN Communication Line | Links all hybrid system modules for data and command exchange |

A single point of failure such as high resistance in the CAN line can stop communication, resulting in the “Cannot Start Engine” message.

Step 3: Detailed Electrical Testing

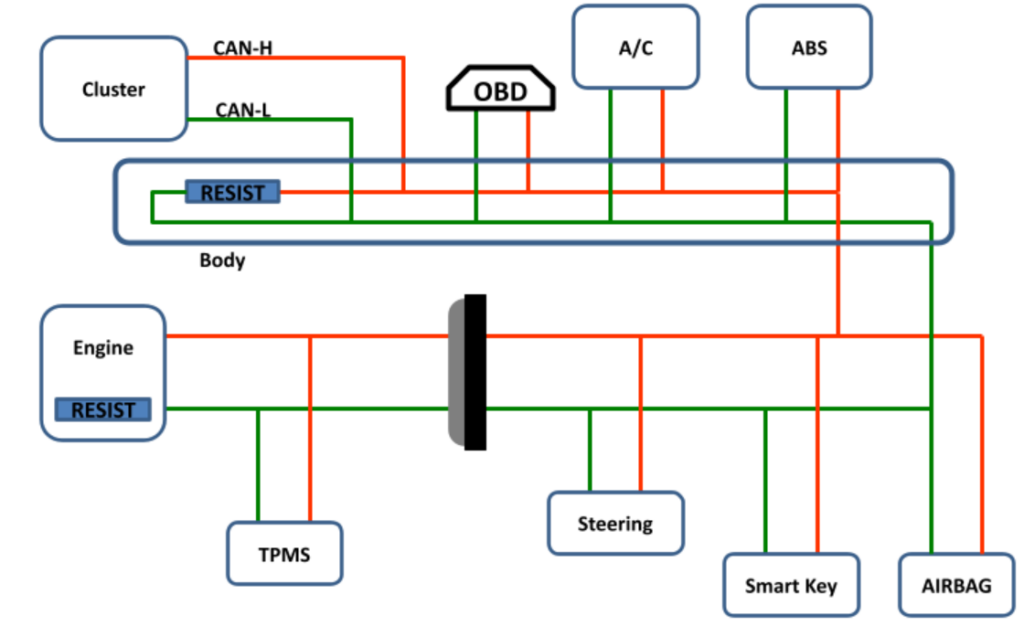

After reviewing wiring diagrams and signal paths, technicians focused on the CAN communication network between the 48V battery system and the starter alternator (ISG).

Tests performed:

- 1. CAN line resistance check → Abnormally high (above 120Ω).

- 2. Continuity test → Revealed a break between the 48V battery and the ISG.

- 3. Voltage drop test → Confirmed the presence of resistance along one leg of the CAN twisted pair.

Diagnosis:

High resistance in the CAN communication line was preventing data exchange between the starter alternator and 48V control system.

Without this signal path, the vehicle could not execute the start command triggering the “Cannot Start Engine – See Owner’s Manual” message.

Step 4: Repair and Rectification

Repair Process

- 1. Inspected the harness route between the rear 48V battery unit and the front-mounted ISG.

- 2. Found corroded pins and partial oxidation at one connector junction likely due to moisture exposure.

- 3. Repaired the affected CAN line, replacing the damaged wire section and cleaning the connector terminals.

- 4. Verified continuity and resistance after repair both within normal range (~60Ω).

Control Unit Initialization

With communication restored, a control unit initial start-up was performed using XENTRY guided functions.

This process:

- – Re-synchronized all drivetrain modules,

- – Cleared historical fault codes, and

- – Re-calibrated voltage parameters for the 48V DC/DC converter and ISG.

Step 5: Successful Start and Verification

After the initialization sequence, the Start/Stop button was pressed again.

The starter alternator engaged, the engine started smoothly, and the “Cannot Start Engine – See Owner’s Manual” message disappeared instantly.

Post-Repair Checks

| Test Parameter | Result |

|---|---|

| 48V battery voltage | Stable at 47.9–48.1 V |

| CAN resistance | 59–61 Ω (within spec) |

| Starter alternator status | Active and responsive |

| Engine start/stop function | Working normally |

| Fault codes | None remaining |

A final test drive confirmed proper regeneration, idle stop/start operation, and hybrid assist all indicating full EQ Boost functionality restored.

Root Cause Summary

| Symptom | Root Cause | Repair |

|---|---|---|

| “Cannot Start Engine – See Owner’s Manual” | High resistance/open circuit in CAN communication line between 48V battery and starter alternator | Repaired damaged wire, cleaned connector, and reinitialized control unit |

This case demonstrates how CAN communication faults can mimic severe hybrid or alternator failures even after part replacement.

Technical Insight: Why CAN Resistance Matters

The Controller Area Network (CAN) is the digital backbone that connects all vehicle modules.

In a 48V hybrid Mercedes:

- – Proper CAN resistance should measure ~60Ω across the network.

- – Any deviation caused by corrosion, broken wires, or poor contact can halt communication, preventing ignition authorization.

That’s why diagnosing communication line integrity is as crucial as replacing physical components.

Preventive Tips for EQ Boost Systems

| Action | Recommendation |

|---|---|

| Regular electrical inspections | Check CAN line connectors for moisture or oxidation during scheduled service. |

| Avoid jump-starting incorrectly | Improper procedures can damage the 48V network or ISG control units. |

| Monitor 48V health | Use XENTRY to verify battery state of charge and DC/DC converter operation. |

| Keep software up to date | Firmware updates often improve EQ Boost network stability and diagnostics. |

Lessons for Technicians

- 1. Don’t replace parts blindly. The external workshop replaced the ISG unnecessarily costly but ineffective.

- 2. Measure network health. CAN diagnostics should always be part of no-start troubleshooting.

- 3. Hybrid systems require OEM tools. Only authorized Mercedes software (XENTRY) can reinitialize 48V control units properly.

Final Outcome

After repairing the high-resistance CAN line and performing control unit initialization:

- – The Mercedes W205 EQ Boost started instantly,

- – All hybrid functions resumed, and

- – The warning message did not reappear after multiple start cycles and road tests.

The customer left fully satisfied, with their EQ Boost system restored to factory performance.

Related Diagnostic Resource

If you’re facing similar starting problems, explore our full troubleshooting hub:

Mercedes No Start Issues: Causes, Fixes & Case Studies : a complete guide covering electrical, fuel, and ECU-related no-start scenarios across multiple Mercedes models.

FAQ

Q1: Why does “Cannot Start Engine – See Owner’s Manual” appear?

This warning indicates a fault in the start authorization or 48V EQ Boost communication network often due to CAN line resistance, battery faults, or control unit issues.

Q2: Can a weak 48V battery cause this issue?

Yes. Low voltage in the 48V circuit can interrupt the start sequence and disable the integrated starter generator.

Q3: Does replacing the starter alternator always fix it?

Not necessarily. As this case shows, the real fault may lie in the CAN wiring or connector corrosion rather than the alternator itself.

Author Bio

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last update: October 2025

Leave a Reply