Table of Contents

Mercedes Jerks When Changing Gears (W223, 9G-Tronic): Case Study, Diagnosis & Fix

A smooth-shifting 9G-Tronic is central to the S-Class experience. When a jerk during gear changes appears, it’s a sign that hydraulic control, fluid condition, or cooling integrity may be off. This case study covers a Mercedes-Benz S-Class W223 with repeatable jerks on upshifts.

The root causes were a failed transmission oil cooler (mixing coolant and ATF) and a compromised valve body. Below you’ll find the investigation steps, repair outline, and prevention tips plus quick-reference tables and an FAQ.

Vehicle & Complaint (Snapshot)

| Item | Detail |

|---|---|

| Model | Mercedes-Benz S-Class W223 |

| Transmission | 9G-Tronic (725.0) |

| Complaint | Jerks on gear changes, most noticeable on light throttle |

| Findings | Cooler failure → coolant–ATF cross-contamination; valve body (mechatronics) performance degraded |

| Fix | Replace transmission oil cooler and valve body, flush system, renew ATF/filter, perform adaptations |

Why Jerking Happens

The 9G-Tronic regulates gear changes by precisely controlling clutch pressures with clean, temperature-stable ATF.

If coolant enters the ATF due to a cooler breach, viscosity and lubricity change, friction elements slip/grab, and solenoids struggle to modulate pressure felt as jerks or shudders. Prolonged contamination can also varnish valve-body passages and damage clutch packs.

Symptom → Cause → First Checks

| Symptom | Likely Cause(s) | Quick Checks |

|---|---|---|

| Light-throttle jerks on upshift | ATF contamination (coolant ingress) | Inspect ATF color/odor; test for glycol; check cooler |

| Jerks + delayed engagement | Valve body wear/varnish; sticky solenoids | Pan inspection (debris), solenoid actuation test |

| Jerks after warmup | ATF thinning; cooler inefficiency | Verify ATF temp; cooler function; fan/cooling circuit |

| Random harsh downshifts | Out-of-date adaptations; low voltage events | Run standstill/running adaptations; battery test |

Diagnostic Workflow (What We Did)

- 1. Road test & data log

Replicated jerks on gentle upshifts. Monitored turbine/internal/output speeds and clutch pressure commands. - 2. ATF inspection

Pull sample: milky tint suggested coolant contamination. Confirmed with glycol test. - 3. Cooling circuit check

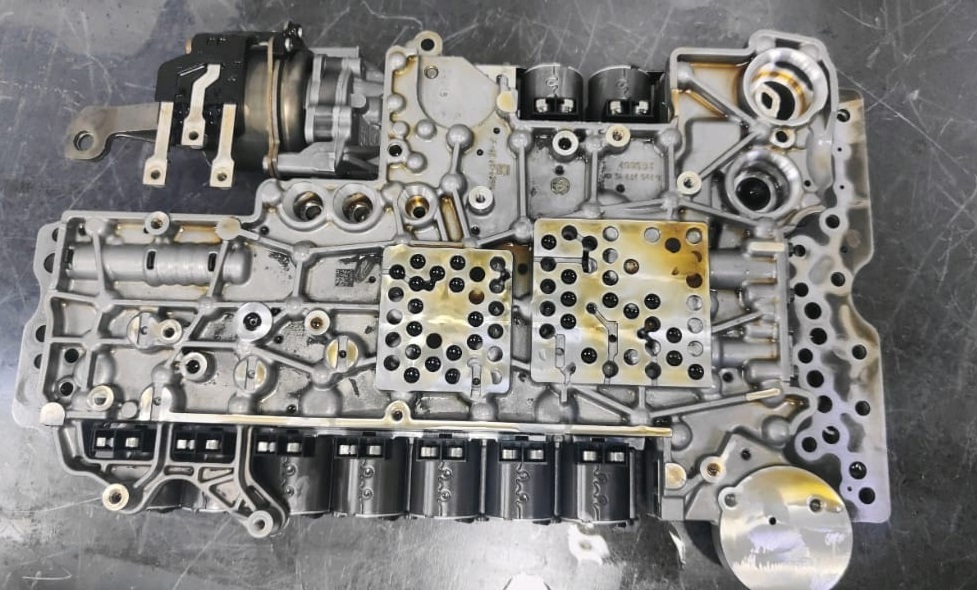

Pressure-tested transmission oil cooler; detected internal breach. - 4. Pan drop & valve body inspection

Found fine debris/varnish; solenoid response inconsistent on bench checks → valve body affected. - 5. Fault memory & preconditions

Scanned with OE tool, verified no blocking DTCs for adaptations. Ensured stable system voltage.

Repair Plan & Execution

1. Replace transmission oil cooler

Stops coolant–ATF mixing and restores proper thermal control.

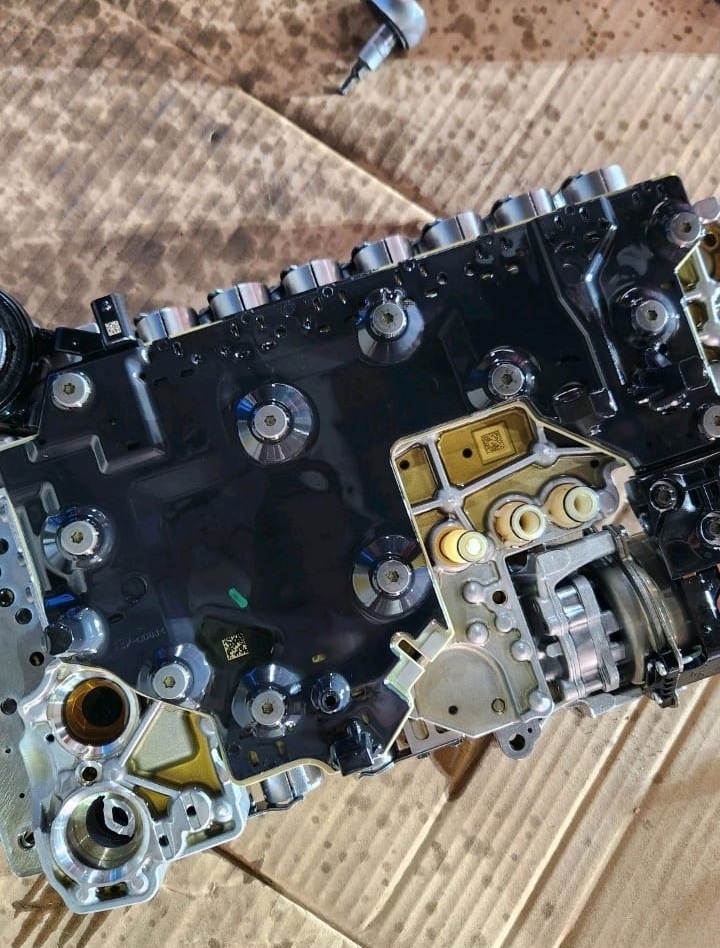

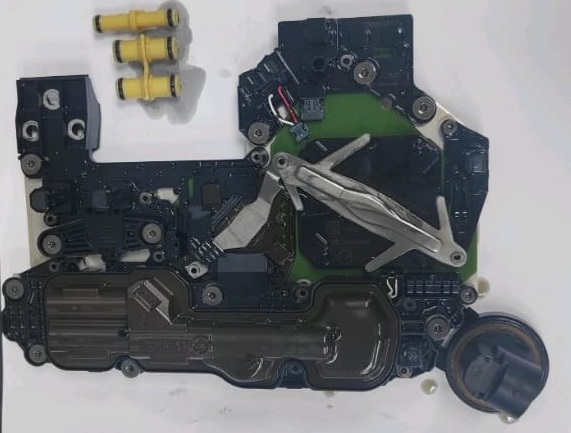

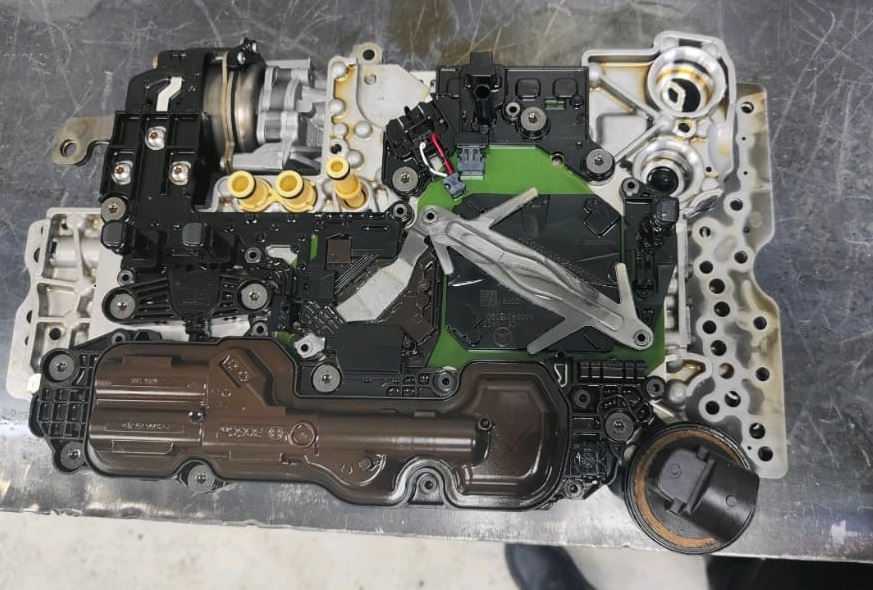

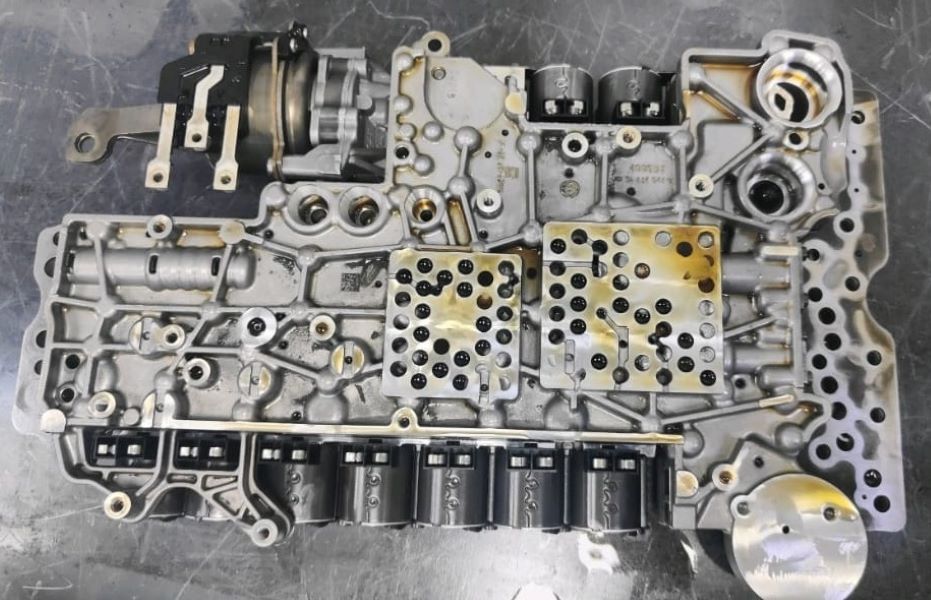

2. Replace valve body (mechatronics)

Resolves sticky modulation and internal hydraulic routing issues caused by contamination.

3. System flush & service

Drain, remove pan, new filter/gasket, flush lines/heat exchanger paths as per procedure, refill with MB-approved ATF, set level at temperature.

4. Adaptations & learning drive

Perform standstill and running adaptations. Complete a structured validation route (city + highway).

Result: Jerks eliminated; shift quality restored; no post-repair DTCs. Follow-up check after heat-soak remained clean.

Explore More Mercedes Transmission Issues

For a deeper dive into gearbox problems slipping into Neutral, delayed/harsh shifts, “Not in P” warnings, and hybrid faults visit our hub: Mercedes Transmission Issues – Causes and Fixes. You’ll find grouped case studies, step-by-step diagnostics, symptom–cause–fix tables, and prevention tips to resolve shifting issues quickly and confidently.

Technician’s Checklist (9G-Tronic)

| Step | Target | Notes |

|---|---|---|

| ATF quality test | No glycol, correct color/odor | Milky/pink = contamination |

| Cooler integrity | No internal leak | Pressure test; check hose joints |

| Valve body health | Consistent solenoid actuation | Replace if responses lag |

| Electrical stability | 12.5–14.5 V during procedures | Use maintainer during adaptations |

| Adaptations | Standstill + running complete | ATF temp within spec, no pending DTCs |

Costs & Time

| Operation | Time | Notes |

|---|---|---|

| Diagnosis & logging | 1.0–1.5 h | Road test + scanning |

| Cooler replacement | 1.5–3.0 h | Model packaging varies |

| Valve body (mechatronics) R&R | 3.0–5.0 h | Clean-room discipline |

| Flush, ATF/filter, level set | 1.0–1.5 h | Temp-based level |

| Adaptations + validation drive | 0.5–1.0 h | Follow prompts exactly |

Actual cost depends on parts pricing and regional labor rates.

Prevention & Maintenance

- – Inspect ATF during service; any pink/milky appearance = stop driving and diagnose the cooler.

- – Replace ATF & filter on sensible intervals (many specialists suggest 60–80k km / 4–5 years).

- – Keep cooling system healthy; overheating or coolant leaks raise risk to the transmission.

- – Maintain battery/charging; low voltage corrupts adaptations and solenoid control.

- – After any battery disconnect/software update, re-run adaptations if shift feel changes.

FAQs: Mercedes Jerks When Changing Gears

1) My W223 jerks only when warm why?

Warm ATF is thinner. If the cooler is weak or ATF is contaminated, the valve body struggles to control pressure precisely, so warm jerks are common. Check cooler health and ATF quality first.

2) Can a fluid change alone fix jerking?

If the cause is mild degradation, sometimes. But coolant-contaminated ATF or a damaged valve body won’t be cured by fluid alone address the cooler and mechatronics.

3) Do I need adaptations after repairs?

Yes. The 9G-Tronic requires standstill/running adaptations so clutch fill and overlap timings are relearned. Skipping this step often leaves residual harshness.

4) Is it safe to keep driving if it only jerks occasionally?

Not advisable. Jerking signals improper clutch control and can accelerate wear. If contamination is present, continued driving risks major internal damage.

5) How can I tell if coolant mixed with ATF?

ATF appears milky/pink and may smell sweet. A glycol test confirms. If positive, do not drive fix the cooler and flush the system.

6) Could engine/trans mounts be the cause?

Worn mounts amplify perceived harshness but rarely cause hydraulic jerks on their own. Inspect mounts after addressing fluid and valve-body causes.

Conclusion

In this W223 S-Class, jerks on gear changes were traced to a failed transmission oil cooler and a compromised valve body. Replacing both, flushing the system, renewing ATF/filter, and completing adaptations restored factory-smooth shifts. If you notice similar symptoms, check ATF quality and cooler integrity first, then evaluate valve body health fix early to protect your 9G-Tronic.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: September 2025

Leave a Reply