Table of Contents

Transmission Delay Shifting: Mercedes Diagnosis & Fix Guide (with Case Study)

Transmission delay shifting hesitation when accelerating, late upshifts, or lag when engaging R/D is common across modern Mercedes models. While many drivers assume “bad gearbox,” the root cause can sit upstream in the engine/turbo control, vacuum network, or electro-hydraulic valve body.

This guide gives you a practical, step-by-step workflow plus a real W205 C300 (M274) case study where a simple vacuum line caused the delay (DTC P029921, Mercedes’ variant of low turbo boost).

Symptoms & Likely Causes (Quick Triage)

| Symptom | Typical Cause(s) | First Actions |

|---|---|---|

| Delayed/harsh shifts at high speed | Low turbo boost (e.g., P029921), intake leaks, vacuum line off | Smoke/vacuum test, inspect intake/vacuum routing |

| Jerky P <-> D / D <-> R engagement | Low/old ATF, worn mounts, sticky solenoids | Check ATF level/condition; scan; mount inspection |

| Cold 2→3 delay (“morning sickness”) | Viscosity + marginal valve body clearances | ATF spec check; adaptation after warmup |

| Harsh shifts during acceleration | Faulty solenoids or TCU/VGS (e.g., P2716), valve body debris | Solenoid/valve body cleaning, verify coil Ω |

| Slips into Neutral / no engagement | Wiring to valve body, selector/ESM comms fault | Harness/pin check; selector status in live data |

Diagnostic Workflow (Do This in Order)

1. Full System Scan (XENTRY/OE-level)

Look for P029921 (low boost), P2716 (pressure control solenoid/K3), P2767 (turbine speed sensor), and any TCU/VGS faults. Save freeze frames.

2. Visual & Vacuum/Intake Inspection

On M274/M270-family engines, disconnected or cracked vacuum hoses and intake pipe leaks are common. Verify wastegate line routing and transducer plumbing.

3. ATF Level & Condition

Use the correct MB spec. Low or dark/burnt fluid amplifies shift delay. Fix leaks, replace filter/pan gasket if needed.

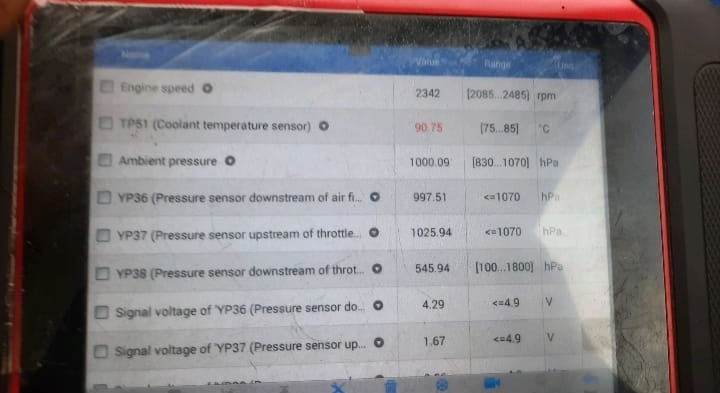

4. Live Data & Actuations

- – Boost pressure vs. target, wastegate duty, MAF.

- – Turbine/input speed, clutch/line pressure, selector status.

Run solenoid actuation tests; watch current profiles.

5. Valve Body & Solenoids (If Indicated)

If codes like P2716 persist, drop the pan, clean valve body/solenoids with fresh ATF, measure coil resistance (confirm spec in WIS).

6. Modules & Programming

Replace only what you prove defective (e.g., VGS/TCU). Perform SCN coding and complete standstill/running adaptations with correct ATF temperature and stable system voltage.

Codes Cheat Sheet

| Code | Meaning (Plain English) | Likely Area | Notes |

|---|---|---|---|

| P029921 | Low turbo boost (Mercedes variant) | Intake/vacuum, wastegate/transducer | Can indirectly delay shifting at speed |

| P2716 | Pressure control solenoid (K3) electrical test failed | Valve body/solenoid, VGS driver | Check coil Ω, wiring, debris |

| P2767 | Input/turbine speed sensor fault | Sensor/harness/TCU input | Causes shift timing errors |

Case Study: C300 (W205, M274): Delayed Shifting at High Speed

Complaint: Noticeable delay in upshifts during highway acceleration; no MIL, but drivability felt “lazy.”

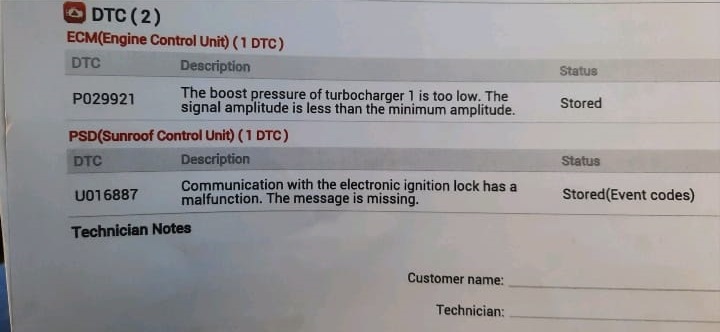

Initial Scan: P029921 present (low boost). No hard TCU/VGS errors.

Step-by-Step

1. Pre-Drive & Live Data

Boost actual lagged target. Mild shift delay aligned with periods of low boost.

2. Wastegate Check

Diaphragm/rod moved smoothly with vacuum hand pump mechanically OK.

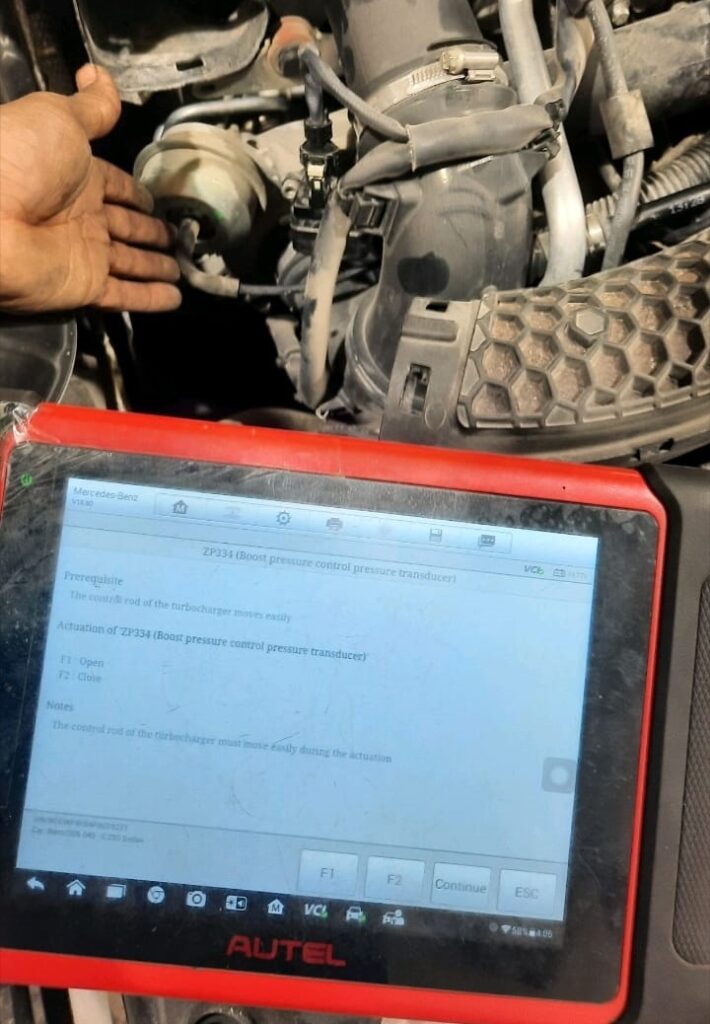

3. Transducer Active Test

Commanded changes didn’t move the rod suspected vacuum feed.

4. Vacuum Trace

Disconnected the intake-to-transducer vacuum pipe and tested suction: none. Traced line to intake manifold → pipe had slipped off.

5. Fix

Reconnected and secured the hose; reassembled. Cleared DTCs. Re-ran active test: wastegate rod moved normally.

6. Validation

Post-repair drive showed restored boost and normal shift timing at speed. No codes returned.

Takeaway: A simple vacuum disconnection starved the turbo of control, lowering boost and indirectly delaying shift scheduling. Not a transmission failure.

Explore More Mercedes Transmission Issues

For a deeper dive into gearbox problems slipping into Neutral, delayed/harsh shifts, “Not in P” warnings, and hybrid faults visit our hub: Mercedes Transmission Issues – Causes and Fixes. You’ll find grouped case studies, step-by-step diagnostics, symptom–cause–fix tables, and prevention tips to resolve shifting issues quickly and confidently.

DIY vs Professional: Who Should Do What?

| Task | DIY | Pro Recommended | Notes |

|---|---|---|---|

| Read/clear basic OBD codes | OK | Use ELM/Bluetooth tools for quick checks | |

| OE-level scan, actuations, adaptations | OK | XENTRY/DTS or equivalent required | |

| Inspect intake/vacuum hoses, clamps | OK | OK | Look for loose, cracked, oil-soaked rubber |

| ATF level/condition check | OK | Follow MB procedure/temperature chart | |

| ATF/filter service, pan gasket | OK | Correct fluid spec and fill procedure matter | |

| Drop valve body & clean solenoids | OK | Risk of damage without experience | |

| Replace solenoid/valve body/VGS | OK | Requires programming + adaptations |

After the Fix: Don’t Skip These

- – Clear codes and perform drive cycle to confirm no recurrence.

- – Ensure ATF temp and battery voltage are within spec before any adaptation.

- – Check for secondary leaks and re-torque clamps after the first road test.

- – If shifts still feel delayed, re-evaluate boost targets, MAF, and exhaust leaks pre-turbine.

Symptom → Cause → Fix

| Symptom | Cause | Fix |

|---|---|---|

| Delay at highway speeds | Low boost (vacuum line off, intercooler leak) | Restore vacuum routing, fix leaks, clear codes |

| Jerky P<->D / D<->R | Low/old ATF, mounts, sticky solenoid | ATF/filter service; inspect mounts; solenoid cleaning |

| Cold 2→3 delay | Fluid viscosity + marginal clearances | Warm-up, confirm fluid spec; adaptations if needed |

| Harsh upshifts, DTC P2716 | K3 solenoid/VGS driver or debris | Coil Ω check; clean valve body; replace faulty part |

| Random Neutral events | Selector/ESM signal drop, harness issue | Check pins/grounds; selector status; repair wiring |

Prevention & Maintenance

- – Vacuum & intake check at service intervals cheap and effective.

- – Use only MB-approved ATF and service at sensible mileage/time, not “lifetime.”

- – Maintain battery/charging health; low voltage ruins adaptations and test logic.

- – After any intake or turbo work, re-verify clamps/hoses post-road-test.

- – If you replace modules, document SCN coding and store pre-repair data.

FAQs

1) Can low turbo boost really delay shifting?

Yes. Mercedes shift logic uses engine torque models. If boost is low, requested torque isn’t achieved, so the TCU delays or reshapes shifts felt as lag at speed.

2) My scan shows P029921 but shifts feel okay, should I care?

You should. It indicates boost control isn’t right. Even if shifts feel acceptable now, drivability and fuel economy suffer, and the issue may worsen.

3) Will a fluid change fix delay shifting?

If the cause is ATF-related (low/old fluid), yes it helps. But fluid won’t fix vacuum leaks, transducer faults, or turbo control issues.

4) When do I suspect the valve body or VGS?

If boost is healthy and you still have pressure/solenoid codes (e.g., P2716) or harsh shifts with correct fluid/temps, investigate valve body debris or VGS driver faults.

5) Do I need adaptations after repairs?

Often yes. Standstill and running adaptations (with correct ATF temp and stable voltage) restore learned pressures/engagement timing.

6) Is it safe to keep driving with delayed shifts?

Not advisable. Prolonged delay/flare can overheat clutches and escalate costs. Diagnose early.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: September 2025

Leave a Reply