Table of Contents

Engine Misfire and Engine Light On: Case Study on Mercedes-Benz G Class W463 with the M177 Engine

For Mercedes-Benz owners, few issues are as concerning as an engine misfire combined with the check engine light. These problems can affect performance, fuel efficiency, and even long-term reliability. In high-performance engines like the M177 twin-turbo V8 found in the Mercedes-Benz G Class W463, misfires can quickly escalate if not addressed properly.

In this article, we’ll examine a real-world case study where a Mercedes G-Class W463 equipped with the M177 engine suffered from misfires and an illuminated check engine light. We’ll detail the symptoms, diagnostic steps, findings, and repair so technicians and owners alike can better understand how to approach this issue.

Vehicle Overview

- Model: Mercedes-Benz G Class W463

- Engine: M177 4.0L V8 Biturbo

- Customer Complaint: Engine misfire and illuminated check engine light

Symptoms Reported

The customer described the following symptoms:

- – Noticeable engine misfire during operation

- – Check engine light illuminated

- – Rough idling, with vibrations especially at low speeds

- – Reduced performance and responsiveness

These symptoms required immediate diagnosis, as prolonged misfires can lead to catalytic converter damage and higher repair costs.

Initial Diagnostic Findings

Using the Mercedes-Benz Xentry diagnostic system, a short test revealed:

- – Fault codes stored in the ME (Motor Electronics) control unit

- – Misfires detected in cylinders 1, 2, 3, and 4

- – Additional fault: “Mixture Too Rich” for cylinder bank one at idle

These results suggested a complex issue involving fuel delivery or emissions systems.

Step-by-Step Diagnostic Process

1. Checking Actual Values and Idle Self-Adjustment

Live data values were analyzed at idle to assess air-fuel mixture balance and cylinder contribution. Abnormalities were present on bank one, confirming that the issue was not random.

2. Fuel High-Pressure Circuit and Sensors

- – Verified that fuel rail pressure sensors and high-pressure circuits were operating correctly.

- – Results showed no irregularities, ruling out pressure-related failures.

3. Injector Performance and Smooth Running Analysis

- – Monitored injector performance data for each cylinder.

- – Checked smooth running values (balance of combustion across cylinders).

- – Findings: No injector imbalance, suggesting the injectors were not the root cause.

4. Reviewing Fault Counter and Fuel Pump Actual Values

- – Cross-checked misfire counters against fuel delivery values.

- – Fuel pumps were operating within manufacturer specifications.

5. Pressure Tests

Performed pressure tests to detect leaks or restrictions.

- – Results: No leaks or pressure inconsistencies found.

Software Updates

Both the ME (Motor Electronics) and FSCU (Fuel System Control Unit) were checked for software updates.

- – Result: No new updates available, confirming this was not a calibration issue but a hardware fault.

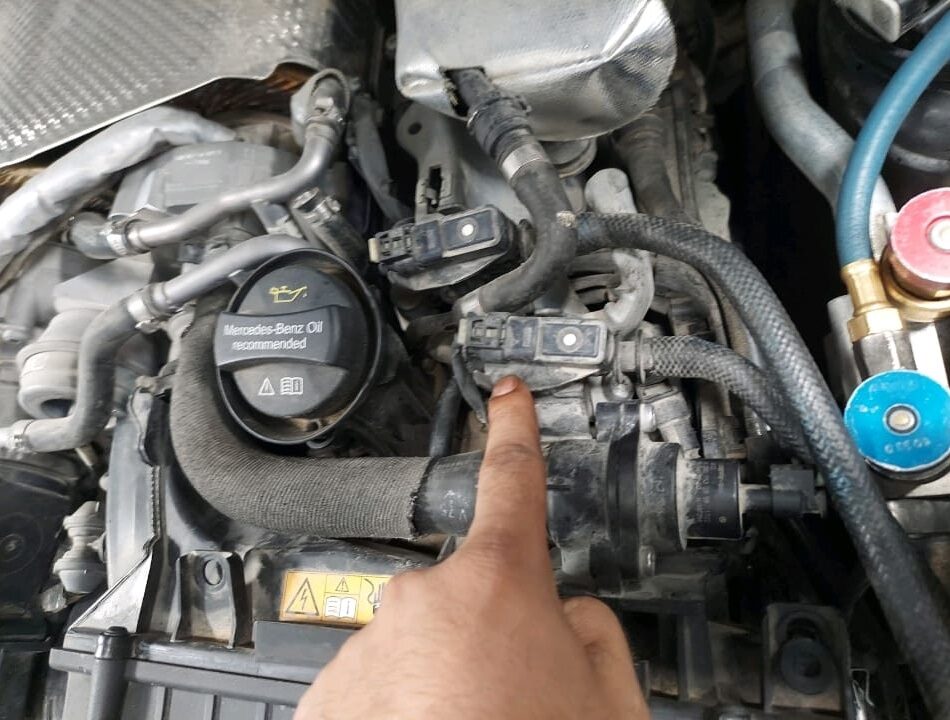

Investigating the Emission System

When standard checks did not isolate the fault, attention turned to the fuel vapor emission system.

- – Charcoal Canister & Lines: Inspected for cracks or blockages. No issues found.

- – Purge Valves: Controlled the release of fuel vapors from the canister into the intake.

Finding: The right bank purge valve was stuck open.

- – Effect: Allowed excessive fuel vapor into the intake system.

- – Result: Rich mixture condition → triggered misfires on bank one.

Resolution

- – The defective purge valve was replaced.

- – Post-repair diagnostics showed no fault codes.

- – Smooth running values returned to normal.

- – Engine light turned off.

- – Final test drive confirmed restored performance and no misfires.

Symptom – Cause – Fix Table

| Symptom | Possible Cause | Fix |

|---|---|---|

| Misfire in multiple cylinders | Faulty purge valve stuck open | Replace defective purge valve |

| Rough idle + rich mixture | Excess vapor entering intake | Inspect and replace purge valve/charcoal canister |

| Misfire with pressure irregularities | High-pressure fuel pump issue | Test and replace pump if values out of range |

| Misfire isolated to 1–2 cylinders | Ignition coil or injector fault | Swap/test coils or injectors |

| Check engine light + mixture codes | Air-fuel imbalance (intake leak or vapor issue) | Inspect emission system and intake lines |

Discover More Mercedes Misfire & Check Engine Light Solutions

For step-by-step guides on diagnosing engine misfires and idle issues, explore our Mercedes Engine Misfire Issues – Causes and Fixes.

To see all the possible reasons your warning light comes on, visit our Mercedes Check Engine Light – Complete Troubleshooting Hub.

Key Takeaways

1. Use Diagnostics Beyond Basic Scans

- – Misfire codes alone don’t reveal root causes analyze live data and fuel mixture values.

2. Check the Emission System

- – Overlooked purge valves and vapor systems can trigger multiple misfires.

3. Systematic Process is Critical

- – By ruling out injectors, pumps, and sensors, technicians avoided unnecessary parts replacement.

4. Final Test Drive is Essential

- – Always confirm repairs under real-world driving conditions.

Preventive Tips for G-Class Owners

- – Regularly inspect ignition components (spark plugs, coils) every 60,000 miles.

- – Service emission system valves during major maintenance intervals.

- – Use premium fuel only, reducing the risk of carbon buildup.

- – Respond promptly to CEL warnings delayed action can cause expensive catalytic converter damage.

- – Run periodic OBD-II scans to detect small misfire trends early.

FAQs on Engine Misfire in Mercedes G-Class

Q1: Why does my Mercedes G-Class show multiple cylinder misfires?

Often linked to fuel delivery or emissions faults such as purge valve failures, not just ignition issues.

Q2: Can a purge valve really cause misfires?

Yes. A purge valve stuck open floods the intake with vapor, creating a rich mixture that triggers misfires.

Q3: What are early signs of a purge valve failure?

Check engine light, rough idle, fuel smell, and misfire codes linked to one cylinder bank.

Q4: How much does it cost to replace a purge valve on a Mercedes G-Class?

Typically €200–€400 depending on labor and part sourcing.

Q5: Can I keep driving with an engine misfire?

Not recommended. Misfires damage catalytic converters and reduce engine life.

Conclusion

The Mercedes-Benz G Class W463 with the M177 engine developed a serious case of engine misfires and a check engine light. Through a step-by-step diagnostic approach, the root cause was identified as a faulty purge valve stuck open an often-overlooked part of the emission system.

Replacing the purge valve restored engine performance, eliminated misfires, and turned off the check engine light.

This case proves the importance of systematic diagnostics, thorough testing, and considering emission system components when resolving misfires. For G-Class owners, addressing issues promptly and keeping up with maintenance ensures the M177 engine continues delivering its legendary performance.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: September 2025

Leave a Reply