Table of Contents

Jerk When Shifting Gears Mercedes (D <-> R): Case Study

A Mercedes-Benz S-Class (W222) with 9G-Tronic (725.0) arrived with a growing jerk when shifting from Drive (D) to Reverse (R) and back. The issue started subtly, then became aggressive enough to risk mount wear and driveline shock.

A full XENTRY scan traced the problem to the Transmission Control Unit (TCU/mechatronics). After replacement, coding, and adaptations, the jerk disappeared and shift feel returned to factory-smooth.

Vehicle & Complaint

| Item | Detail |

|---|---|

| Model | Mercedes-Benz S-Class (W222 or similar) |

| Transmission | 9G-Tronic (725.0) |

| Complaint | Jerk/bump when selecting D <-> R, sometimes with a slight delay |

| Warning lights | Often none; may store transmission/TCU DTCs |

| Root cause (this case) | TCU/mechatronics internal fault causing erratic range engagement control |

| Fix | Replace TCU/mechatronics, program (SCN code), run adaptations, verify with road test |

Symptoms & Likely Causes

| Symptom | Likely Cause(s) | Quick Checks |

|---|---|---|

| Sharp jerk when shifting D → R or R → D | TCU/mechatronics control fault, outdated adaptations | XENTRY scan for TCU DTCs; check adaptation status |

| Delay, then a thump on engagement | Low/incorrect ATF, adaptation drift | Verify ATF spec/level at temp; run adaptations if eligible |

| Intermittent harshness warm or cold | Solenoid modulation error; TCU internal error | Review live data (range request vs actual; turbine/output speeds) |

| Added driveline shudder | Worn mounts/prop shaft lash (secondary) | Inspect engine/trans mounts and joints after fixing primary fault |

Diagnostic Workflow (Used in This Case)

1. Global XENTRY short test

- – DTCs indicated signal interruption/internal error in the transmission control module.

- – No hard faults elsewhere; power/grounds stable.

2. Live-data review

- – Range change requests vs. actual showed irregular engagement timing.

- – No signs of low ATF pressure or speed-sensor failure.

3. Rule-outs

- – ATF level/condition within spec.

- – No abnormal vibration from mounts or prop shaft to explain the jerk alone.

Conclusion: The pattern matched a TCU/mechatronics failure in the 9G-Tronic.

Repair Process: 9G-Tronic TCU/Mechatronics Replacement

1. Power down & protect

- – Connect a battery maintainer; memory-safe procedures.

- – Ignition off per WIS; observe HV/airbag precautions as applicable.

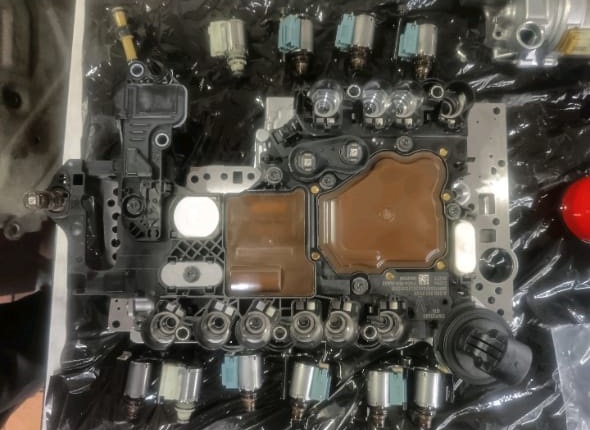

2. Access the mechatronics

- – Remove under-tray, drain ATF to spec procedure.

- – Remove transmission pan & filter; access the mechatronics/TCU assembly.

3. Replace the TCU/mechatronics

- – Carefully disconnect the internal connector; avoid pin damage.

- – Install new OEM unit, renew seals/gaskets, fit new filter.

4. Reassembly & ATF service

- – Clean mating surfaces; refit pan with new gasket.

- – Refill with MB-approved ATF and set level at temperature per WIS.

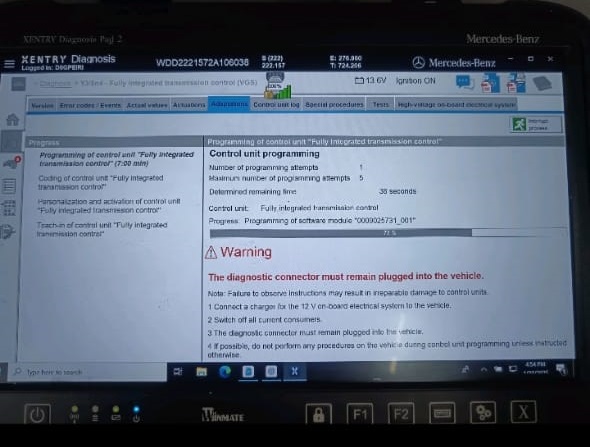

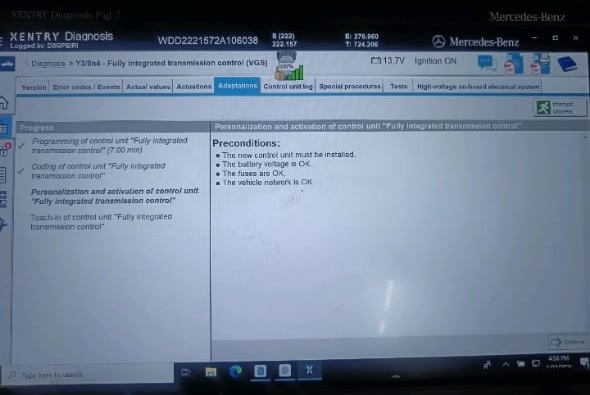

5. Programming & adaptations

- – Perform SCN coding (online/programming) to pair the TCU to the car.

- – Run Standstill & Running Adaptations with XENTRY: correct ATF temperature, stable voltage, no blocking DTCs.

6. Validation

- – Cycle P-R-N-D repeatedly; confirm smooth, prompt engagement both cold and warm.

- – Road test (urban + gentle maneuvers) and final scan.

Result: D <-> R jerk eliminated; normal range engagement at all temperatures; zero returning DTCs.

Explore More Mercedes Transmission Issues

For a deeper dive into gearbox problems slipping into Neutral, delayed/harsh shifts, “Not in P” warnings, and hybrid faults visit our hub: Mercedes Transmission Issues – Causes and Fixes. You’ll find grouped case studies, step-by-step diagnostics, symptom–cause–fix tables, and prevention tips to resolve shifting issues quickly and confidently.

Technician’s Quick Tables

Symptom → Cause → Fix

| Symptom | Likely Cause | Recommended Fix |

|---|---|---|

| D<->R jerk with slight delay | TCU internal fault; control logic not actuating smoothly | Replace TCU/mechatronics, program, adapt |

| Mild clunk only when hot | ATF level marginal; adaptations drifted | Verify ATF level/spec, run adaptations |

| Persistent harshness after TCU | Missed adaptations; mount lash | Re-run adaptations; inspect mounts/prop shaft |

Tools & Preconditions

| Category | Requirement |

|---|---|

| Diagnostics | XENTRY/STAR for coding + adaptations, live data |

| Fluids | MB-approved ATF for 9G-Tronic; new filter & pan gasket |

| Electrical | Stable 12.5–14.5 V during programming/adaptations |

| Info | WIS/ASRA for torque specs, level temps, sequences |

| Safety | PPE; hot ATF + under-car procedures |

Time & Cost (Indicative)

| Operation | Typical Time | Notes |

|---|---|---|

| Diagnosis & live data | 1.0–1.5 h | Includes rule-outs |

| Mechatronics R&R | 3.0–4.5 h | Model packaging varies |

| ATF/filter service & level set | 0.8–1.2 h | Temp-based procedure |

| Coding & adaptations | 0.5–1.0 h | Requires STAR/XENTRY |

Parts & labor vary by region; expect $1,000–$2,500 total with OEM unit and programming.

Live-Data Targets

| Parameter | Healthy Behavior | Red Flags |

|---|---|---|

| Range request vs actual | Prompt match, no overshoot | Lag + sudden torque spike (jerk) |

| Turbine vs output speed | Predictable change at selection | Erratic spike/drop at D<->R |

| Solenoid/pressure command | Smooth ramps | Abrupt, inconsistent commands |

| DTC memory | No current DTCs | TCU internal/communication errors |

Prevention & Maintenance

- – Service ATF & filter at sensible intervals (many specialists: 60–80k km / 4–5 years), even if labeled “lifetime.”

- – Keep battery/charging healthy low voltage corrupts adaptations and module behavior.

- – After software updates, battery replacement, or module work, complete adaptations if shift feel changes.

- – Address minor engagement thumps early they rarely self-heal and can stress mounts and clutches.

More information in the next article : Mercedes 9G Tronic Oil Change Guide: Cost & Interval

FAQs: Jerk When Shifting Gears Mercedes

1) Can low transmission fluid cause a D<->R jerk?

Yes. Low/incorrect ATF can delay clutch fill and cause a thump. Verify ATF level and spec first. If level is correct and the jerk persists with TCU DTCs suspect mechatronics/TCU.

2) Is it safe to drive with a noticeable jerk when selecting D<->R?

Not recommended. Each harsh engagement stresses clutches, mounts, and driveline. Continued use can escalate wear and costs. Diagnose and repair promptly.

3) Does a TCU replacement require programming?

Absolutely. The new unit must be SCN coded to the VIN and configured to the exact transmission variant. Then run adaptations so clutch fills and overlaps relearn correctly.

4) Could engine/transmission mounts be the cause?

Worn mounts amplify the sensation but rarely create the hydraulic control fault. Fix the TCU/ATF/adaptations first; then evaluate mounts if any residual feel remains.

5) Will a simple fluid change fix it?

If the cause is marginal ATF or adaptation drift, maybe. But a TCU internal error won’t be cured by fluid alone you’ll need mechatronics replacement + coding + adaptations.

6) What causes TCU failure on 9G-Tronic?

Typical triggers include internal hardware faults, thermal stress, voltage spikes, and rare contamination incidents. Software corruption and failed updates can also present as control faults.

Conclusion

In this S-Class 9G-Tronic, a persistent D<->R jerk traced to a failing TCU/mechatronics. Replacing the unit, programming, and completing adaptations restored smooth range engagement, cold and warm. Use a disciplined workflow—scan → rule out ATF/voltage → validate with live data → replace/program mechatronics → adapt → road-verify—to solve the problem once, properly.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: September 2025

Leave a Reply