Table of Contents

Knock Sound in Engine: A Case Study on Mercedes-Benz C300

In the world of automotive diagnostics, identifying and resolving engine issues is crucial for maintaining vehicle performance and longevity. One common issue that can cause concern is a “Knock Sound in Engine”.

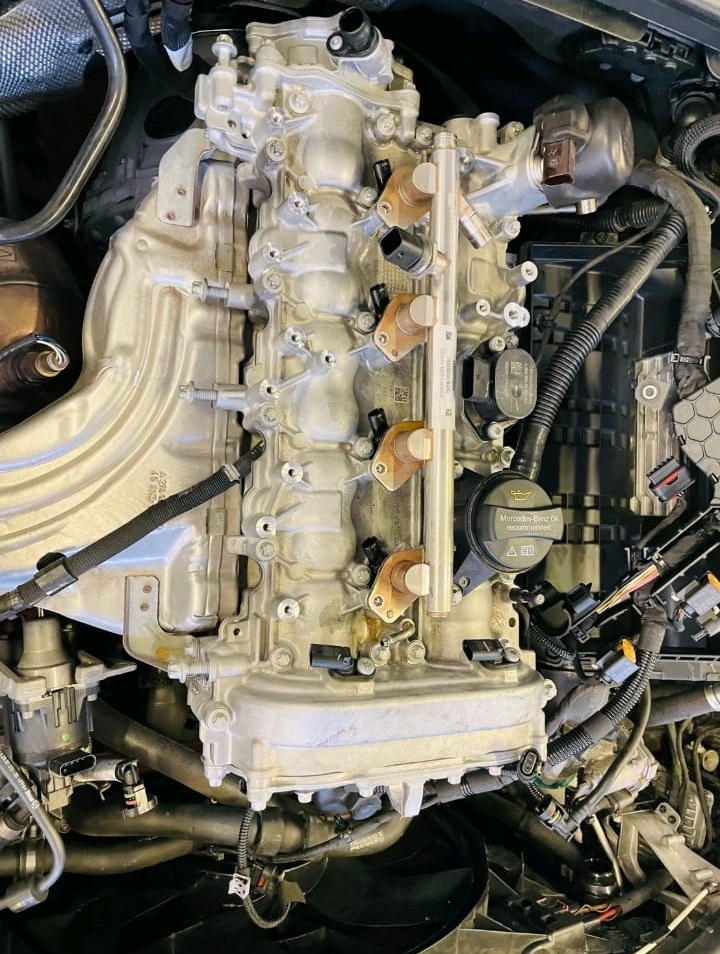

This article delves into a real-world case involving a Mercedes-Benz C300 W205 equipped with the M264 Engine, where a persistent knock sound was detected. We will explore the diagnostic process, uncover the root cause, and discuss the successful resolution of this issue.

Vehicle Overview: Mercedes-Benz C300 W205

The Mercedes-Benz C300 W205 is known for its blend of luxury, performance, and advanced engineering. Equipped with the M264 engine, a turbocharged four-cylinder unit, it delivers a balance of power and efficiency. However, like any complex machine, it is not immune to issues that can arise over time, such as the “Knock Sound in Engine.”

Complaint: Knock Sound in Engine

The vehicle in question arrived at the workshop with a clear customer complaint: a “Knock Sound in Engine.” This noise, often indicative of internal engine problems, demanded immediate attention to prevent further damage. The first step was to verify the customer’s concern and systematically diagnose the issue.

Diagnostic Process

Upon receiving the vehicle, I performed a thorough diagnostic process using Mercedes-Benz’s Xentry Star Diagnosis system. This advanced diagnostic tool is essential for pinpointing issues within the complex network of engine components in modern vehicles.

Verifying the Concern

The first step was to listen to the engine and verify the knock sound reported by the customer. The noise was consistent and clearly coming from within the engine, confirming the need for a deeper investigation.

Fault Codes Detected

The Xentry Star Diagnosis revealed multiple fault codes within the Engine Control Unit (ECU), specifically related to the CAMTRONIC system. The CAMTRONIC system is responsible for variable valve timing, optimizing engine performance and efficiency. Any malfunction in this system can lead to various engine issues, including unusual sounds.

Investigating the CAMTRONIC System

Given the fault codes related to the CAMTRONIC system, the next step was to inspect the CAMTRONIC components. The CAMTRONIC actuator, which adjusts the camshaft’s position, was functioning correctly. However, to be thorough, I decided to examine the camshaft itself.

Removing the Camshaft

Removing the camshaft is a delicate and time-consuming process, requiring precision to avoid further damage. Once the camshaft was removed, I carefully inspected it for any signs of wear or damage that could be causing the knock sound in the engine.

Diagnosis: Damaged Camshaft

Upon inspection, it was evident that the camshaft had sustained damage, which was the root cause of the “Knock Sound in Engine.” The wear on the camshaft was significant enough to interfere with the proper functioning of the engine’s valve timing, leading to the knocking noise.

Solution: Camshaft Replacement

With the diagnosis confirmed, the only viable solution was to replace the damaged camshaft. This replacement was carried out with utmost care, ensuring that all components were correctly aligned and that no further issues would arise.

Outcome: Problem Solved

After replacing the camshaft, the engine was reassembled, and the vehicle was started. The knock sound in the engine was no longer present, confirming that the issue had been successfully resolved. A final diagnostic check showed no fault codes, and the CAMTRONIC system was operating as intended.

Conclusion

The case of the Mercedes-Benz C300 W205 with the M264 engine highlights the importance of a thorough diagnostic process when addressing issues like a “Knock Sound in Engine.”

By utilizing advanced diagnostic tools and carefully inspecting key components, it is possible to accurately diagnose and resolve even complex engine problems. This case study serves as a valuable lesson in the importance of precision and attention to detail in automotive repair, ensuring that vehicles continue to perform at their best.

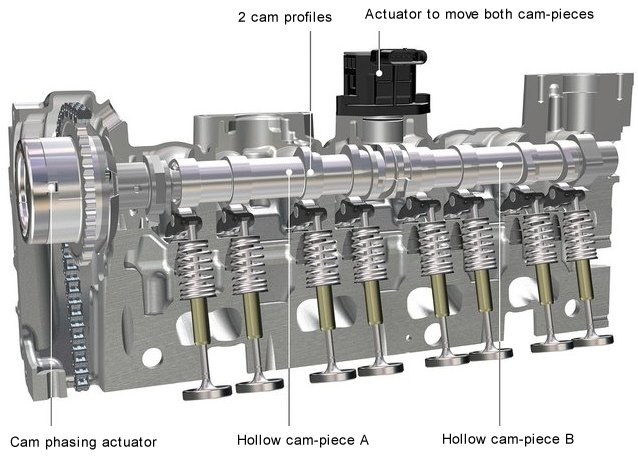

CAMTRONIC System

CAMTRONIC is an advanced variable valve lift system used in Mercedes-Benz engines. It enhances engine efficiency, performance, and emissions by allowing the engine to adjust the valve lift based on driving conditions.

How CAMTRONIC Works

The CAMTRONIC system allows for variable control of the intake valves’ lift height. This adjustment is made possible by a special actuator that changes the position of the camshaft lobes. The system can switch between two different cam profiles: one for low lift (better fuel efficiency at low speeds) and one for high lift (improved power output at higher speeds). This enables the engine to optimize performance and fuel economy depending on the driver’s needs.

Key Benefits of CAMTRONIC

- Improved Fuel Efficiency: By optimizing valve lift for different driving conditions, CAMTRONIC helps reduce fuel consumption, especially during city driving or at low engine loads.

- Enhanced Performance: The system ensures that the engine delivers maximum power when needed, particularly during acceleration or high-speed driving.

- Lower Emissions: By improving combustion efficiency, CAMTRONIC contributes to lower CO2 emissions, making the engine more environmentally friendly.

- Smooth Operation: The ability to switch seamlessly between different valve lift profiles ensures that the engine operates smoothly, without the need for abrupt changes in performance.

Common Issues with CAMTRONIC

While CAMTRONIC is a highly effective system, it can be prone to issues if components wear out or fail. Common problems include:

- Faulty Actuator: The CAMTRONIC actuator may fail, leading to improper valve lift adjustment.

- Camshaft Wear: Over time, the camshaft may experience wear and tear, causing issues with valve timing and potentially leading to engine noises such as knocking.

Conclusion

CAMTRONIC is a critical component in modern Mercedes-Benz engines, balancing performance, efficiency, and emissions. Understanding its function and potential issues is essential for diagnosing and repairing engine problems effectively.

Leave a Reply