Table of Contents

Mercedes Gear Shift Not Working (GLC): Case Study,

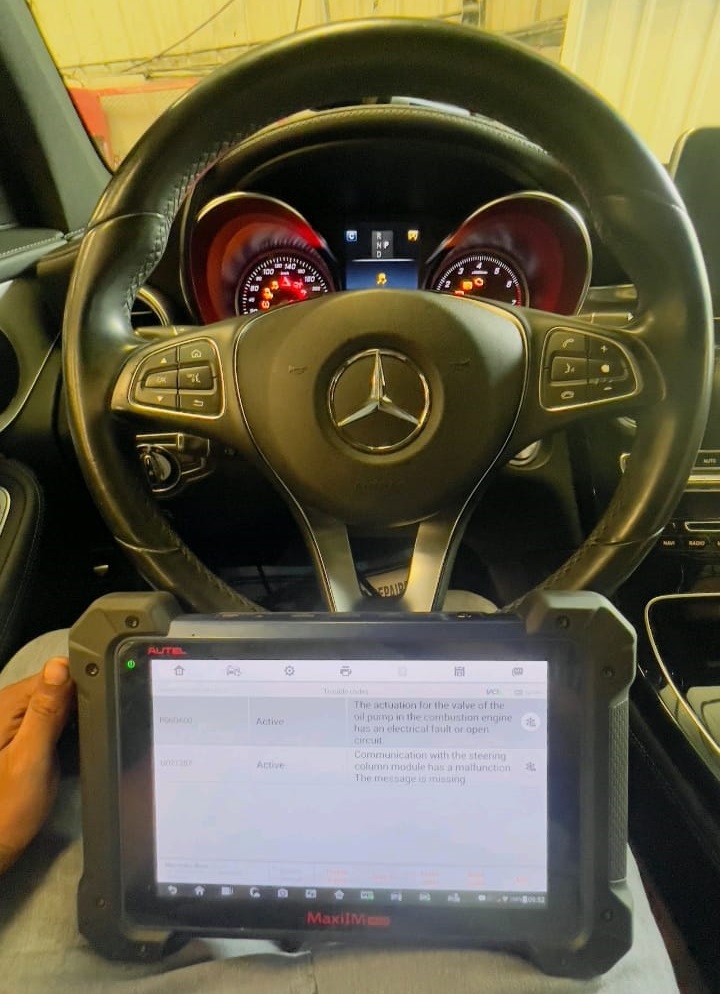

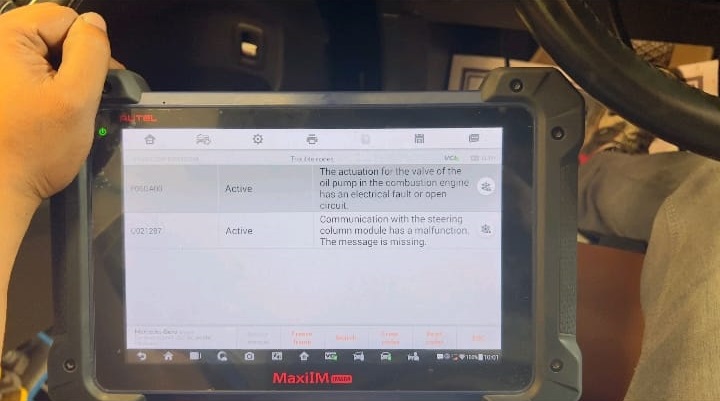

A Mercedes-Benz GLC arrived at the dealership with a scary combo of symptoms:

- – the gear shift wouldn’t work (vehicle wouldn’t move),

- – the horn was dead, and

- – steering-wheel switches didn’t respond.

A scan with an AUTEL tool showed lost communication with the steering column module and that the steering-wheel/sensor wasn’t initialized. Root cause: a failed steering column module (MRM) the same network hub that handles the DIRECT SELECT column shifter signals, horn, and wheel buttons. Replacing and programming the MRM restored all functions, including gear selection.

Vehicle & Complaint

| Item | Detail |

|---|---|

| Model | Mercedes-Benz GLC (DIRECT SELECT column shifter) |

| Complaint | Gear shift not working / vehicle won’t move, horn inoperative, steering-wheel controls dead |

| Initial scan | Communication fault with Steering Column Module (MRM); steering-wheel sensor not initialized |

| Root cause | MRM failure (steering column module / clock spring assembly) causing network message loss |

| Fix | Replace MRM, program & initialize module; confirm CAN communication; verify gear engagement, horn, and buttons |

Why one module broke so much at once

On modern Mercedes models, the MRM sits behind the wheel and:

- – routes the gear selector (DIRECT SELECT) commands to the transmission control unit (EGS/TCU),

- – handles horn logic,

- – reads and broadcasts steering-wheel switch inputs, and

- – provides steering angle and other signals to the car’s CAN network.

If the MRM loses power/ground, wiring, or just fails internally, the car won’t see a valid range request, and you’ll get no gear engagement, plus “mystery” failures like a dead horn and buttons.

Symptoms → Likely Causes → Quick Checks

| Symptom cluster | Likely cause(s) | Quick checks |

|---|---|---|

| Gear shift on column won’t respond; car won’t move | MRM offline, blown fuse, CAN wiring fault, failed clock spring | Scan for MRM communication; check MRM fuses/power/ground; inspect spiral cable |

| Horn inoperative + steering-wheel buttons dead | MRM failure or clock spring break | Continuity across clock spring; live data for button/horn inputs |

| “Sensor not initialized” messages | MRM replaced / lost coding / low voltage event | Run initialization & coding; battery/charging test |

| Intermittent behavior when turning wheel | Damaged spiral cable (clock spring) | Wiggle test while monitoring live inputs; replace assembly if open-circuiting |

Low voltage can mimic module failures. Always baseline battery/charging before condemning parts.

Diagnostic Workflow (Used in this case)

1. Global scan (AUTEL/OE-level)

- – Communication DTCs for MRM; actual values showed steering-wheel sensor not initialized.

- – Transmission module did not receive valid range requests.

2. Power & ground sanity

- – Verified MRM fuses, feed, and grounds (per WIS). No drops under load.

3. Network integrity

- – CAN lines at MRM within expected resistance (bus healthy). No corrosion at connectors.

4. Clock spring/spiral cable check

- – No open circuits on rotation, but MRM remained non-responsive → internal MRM fault.

Conclusion: Replace MRM and initialize/codify.

Repair Process: Steering Column Module (MRM) Replacement

Safety first: Airbag/steering work requires proper procedures and PPE. If unsure, leave this to a qualified technician.

1. Power down & prepare

- – Save settings, connect a battery maintainer.

- – Disable SRS per WIS, then disconnect battery (observe airbag wait time).

2. Airbag & wheel removal

- – Release driver airbag (proper tools).

- – Mark wheel position, remove steering wheel without disturbing clockspring centering.

3. Remove clockspring/MRM assembly

- – Disconnect MRM connectors.

- – Inspect pins for corrosion; check harness strain relief.

4. Install new MRM

- – Center clockspring per instructions (do not rotate off center).

- – Refit wheel to the alignment marks; torque to spec.

5. Reassemble & power up

- – Reinstall airbag, reconnect battery.

6. Programming & initialization

- – Program/coding of new MRM to vehicle (variant coding).

- – Initialize steering-wheel sensor / steering angle sensor as applicable.

- – Clear DTCs across MRM, EGS/TCU, ESP, and instrument cluster.

7. Functional checks

- – Verify gear selection (P-R-N-D), horn, steering-wheel buttons, and steering angle values.

- – Road test; confirm no returning faults.

Result: Gear shift worked normally, the vehicle moved as expected, horn and wheel controls returned, and no communication errors remained.

Explore More Mercedes Transmission Issues

For a deeper dive into gearbox problems slipping into Neutral, delayed/harsh shifts, “Not in P” warnings, and hybrid faults visit our hub: Mercedes Transmission Issues – Causes and Fixes. You’ll find grouped case studies, step-by-step diagnostics, symptom–cause–fix tables, and prevention tips to resolve shifting issues quickly and confidently.

Technician’s Tables

Tools & Preconditions

| Category | Requirement |

|---|---|

| Diagnostics | AUTEL or XENTRY/STAR for coding & initialization |

| Power | Stable 12.5–14.5 V during coding; battery maintainer |

| Info | WIS/ASRA procedures, torque specs, fuse maps |

| Safety | SRS handling, clockspring centering, PPE |

Time & Cost (Indicative)

| Operation | Typical time | Notes |

|---|---|---|

| Full diagnostics & network checks | 0.8–1.2 h | Includes voltage & fuse checks |

| Airbag & wheel removal | 0.4–0.7 h | Model-specific |

| MRM (steering column module) R&R | 0.8–1.5 h | Includes clockspring handling |

| Coding/initialization & final test | 0.4–0.8 h | Requires OE-level tool |

Costs vary by region; expect parts + labor commonly in the mid-three to low-four figures, depending on module price.

Symptom–Cause–Fix

| Symptom | Cause | Fix |

|---|---|---|

| Gear shift on steering column not working | MRM failure or no communication | Replace/codify MRM, initialize sensors |

| Horn + wheel buttons dead | MRM or clock spring open | Replace MRM/clock spring as needed |

| “Sensor not initialized” after battery work | Configuration lost | Run initialization/coding procedure |

| Still no shift after MRM | ATF/EGS issue, selector lever fault, blown fuse elsewhere | Scan EGS; check selector lever wiring; verify fuses and grounds |

Preventive Tips

- – Keep the battery & charging system healthy (low voltage = module chaos).

- – Avoid turning the steering wheel with the clockspring removed; always center before install.

- – After steering column or alignment work, calibrate steering angle to prevent assistance/ESP faults.

- – Don’t ignore multi-system symptoms (horn + buttons + shift): it’s usually one shared module diagnose holistically.

FAQs: Mercedes Gear Shift Not Working

1) Why did the gear shift, horn, and wheel buttons fail together?

They’re all routed through the MRM. When the module is offline or corrupted, the car can’t “see” gear requests, horn commands, or button inputs so it treats the gear command as invalid and won’t move.

2) Do I always need programming after replacing the MRM?

Yes. The new module must be coded/initialized to your VIN and options, and the steering angle/wheel sensors must be initialized so other systems (ESP, assistance features) trust the signals.

3) Can low battery cause a “gear shift not working” complaint?

Indirectly, yes. Low voltage can knock modules offline, corrupt initialization, and cause comm errors. Always baseline voltage and grounds before replacing electronics.

4) Could this be a simple fuse?

Sometimes. A blown MRM feed/ignition fuse will create the same symptom cluster. Check relevant fuses per WIS before condemning the module.

5) Can I drive the car if the gear shift on the steering column is unresponsive?

If the car won’t engage a drive range, don’t force it. You risk further faults or being stranded. Diagnose and repair first.

6) Do paddle shifters have anything to do with this?

Paddles also route via the MRM. If paddles, horn, and buttons are dead, suspect the column module/clock spring or power/ground to it.

7) Is the clock spring always replaced with the MRM?

Not always, but many MRM assemblies are supplied with the integrated spiral cable. If your spiral cable shows open-circuit when turning, replace it to prevent comebacks.

Conclusion

In this Mercedes GLC, the “gear shift not working” complaint wasn’t a transmission failure at all it was a network hub failure in the steering column module (MRM). Replacing and programming the MRM, initializing the steering-wheel/angle sensor, and verifying communication restored gear selection, horn, and buttons. If you see this exact trio of symptoms, start with the MRM: power/ground → scan → clock spring → module → code/initialize → verify.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: September 2025

Leave a Reply