Table of Contents

Mercedes Hybrid Transmission Malfunction (E300): Real Fix [Case Study]

When a Mercedes E300 Hybrid throws a “Transmission Malfunction – Visit Workshop” message or suddenly loses propulsion, it’s scary and potentially expensive if you guess at parts. Hybrids add extra complexity (e-machine, inverter, HV battery, regenerative braking), so a transmission complaint can be mechanical, hydraulic, electrical, or software-integration related.

Quick Facts (Case Snapshot)

| Item | Detail |

|---|---|

| Vehicle | Mercedes-Benz E300 Hybrid (E-Class) |

| Complaint | Transmission malfunction + vehicle stopped |

| XENTRY Live Data | Turbine speed 0, internal speed 0, output speed 0 |

| Root Cause (this case) | Damaged input shaft, wear in front intermediate housing, failed start-off clutch |

| Fix | Transmission disassembly → replace input shaft & start-off clutch → reassemble → validate with live data & road test |

| Who should repair | HV Level 3/4 qualified technician; follow WIS/ASRA and HV safety procedures |

High-voltage safety: Hybrids require proper shutdown/lockout and PPE. Don’t attempt drivetrain removal or inverter/disconnection without HV training.

How the E300 Hybrid Driveline Works (Why It Matters)

The E300 Hybrid blends a conventional automatic gearbox with an e-machine and regenerative braking. Shift quality and propulsion depend on accurate speed sensing (turbine, internal, output), clutch pressure control, and hybrid torque blending.

If the transmission can’t transmit torque (e.g., start-off clutch failure or input shaft damage), the control unit will see zero speeds and may shut propulsion down to protect components.

Symptoms of Hybrid Transmission Malfunction

- – Warning in cluster: “Transmission Malfunction” / drivetrain warning lamp

- – Loss of drive or sudden stop; car may only creep or not move at all

- – Erratic/harsh shifts, delayed engagement, or no gear

- – Jerks during start-off or regenerative transitions

- – Whine/grind noises (mechanical damage)

- – Intermittent limp mode after heat soak or heavy city traffic

Diagnostic Workflow

1. Global scan (XENTRY/OE-level)

Pull DTCs from TCU/EGS, Engine/Hybrid, ESP, Inverter/Hybrid Controller, HV Battery. Save freeze frames.

2. Live data triage

Observe turbine/internal/output speeds, gear request vs. actual, clutch pressures, e-machine torque.

- – If all speeds stay at 0 rpm while engine runs and D is engaged → suspect mechanical decoupling (start-off clutch, input shaft, stripped splines).

3. Basic prerequisites

ATF level/condition, battery voltage stability, no HV isolation errors. Contaminated ATF or low voltage can mislead diagnostics.

4. Electrical vs mechanical decision

- – Electrical: speed sensor DTCs, harness faults, corrupted coding → test sensors/wiring, software, module power/grounds.

- – Mechanical: no abnormal sensor DTCs yet speeds don’t rise with throttle → inspect clutch packs/shafts/gear train.

5. WIS/ASRA-guided teardown (if mechanical is suspected)

Drain ATF, remove transmission, strip valve body and front intermediate housing, inspect input shaft & start-off clutch.

6. Repair + controlled reassembly

Replace worn/faulty parts, renew seals/gaskets, set clearances per WIS. Use correct MB ATF spec and fill procedure.

7. Validation

Clear DTCs → recheck live speeds (turbine/internal/output now climb with throttle) → road test with logs.

Case Study: E300 Hybrid Stopped with All Speeds at 0 rpm

Complaint: Transmission malfunction lamp; vehicle suddenly stopped and could not move.

Initial XENTRY data:

- – Turbine speed: 0 1/min

- – Internal transmission speed: 0 1/min

- – Output speed: 0 1/min

Interpretation: With engine running and D selected, all three staying at 0 strongly suggests no torque transfer past the input a mechanical decoupling.

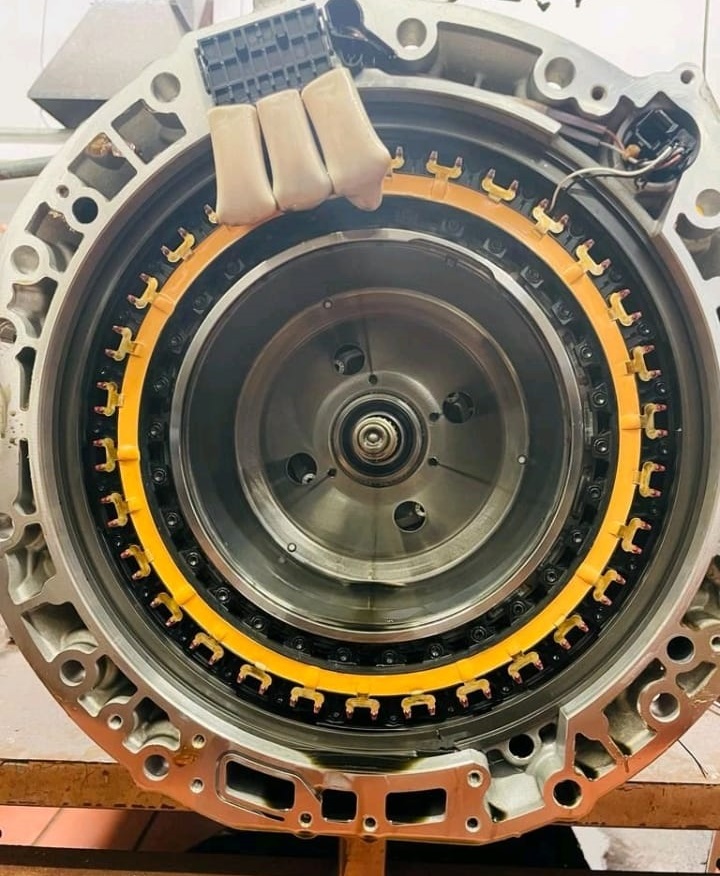

Teardown findings:

- – Input shaft damaged (spline wear/deformation)

- – Front intermediate housing worn

- – Start-off clutch out of spec (thermal/mechanical damage)

Repair steps:

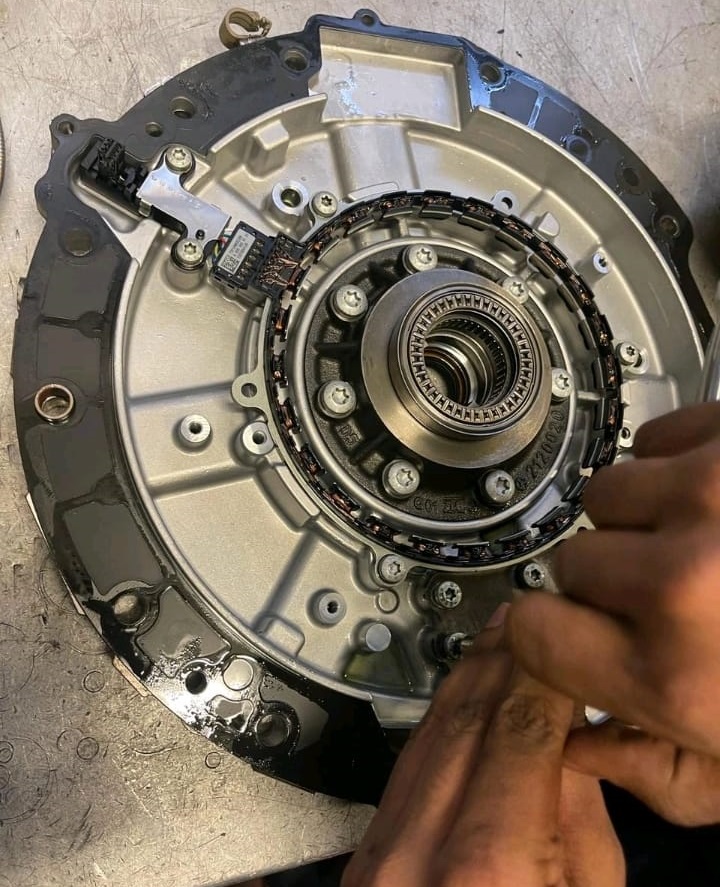

1. Remove transmission and front intermediate housing; disassemble start-off clutch.

2. Inspect all rotating members and bearings for debris trails/blueing.

3. Replace input shaft and start-off clutch; renew seals, filter, pan gasket.

4. Reassemble per WIS torque and alignment specs; refill with correct MB ATF and perform level set at temperature.

5. Clear codes; run guided tests/adaptations if requested by XENTRY.

Result: Post-repair live data normal turbine/internal/output speeds rise smoothly with throttle; vehicle drives normally; no return of DTCs.

Live-Data Decoder (Speeds & What They Mean)

| Data Channel | What It Represents | What “0 rpm” Suggests |

|---|---|---|

| Turbine speed | Input to the gearbox from the torque path (engine/e-machine blend) | No torque into box (sheared/stripped input, failed start-off clutch) |

| Internal speed | Intermediate train/clutch pack resultant | No internal transmission of torque |

| Output speed | Prop shaft/drive output | Vehicle not moving / no torque reaching output |

Symptom → Likely Cause → First Fix

| Symptom | Likely Cause(s) | First Actions |

|---|---|---|

| No movement; speeds all 0 rpm in D | Start-off clutch failure, input shaft/spline damage | Mechanical inspection; teardown as per WIS |

| Harsh engagement; grinding | Worn clutch pack, bearing damage | ATF inspection for metal; valve body & hardware check |

| Intermittent limp after heat | ATF breakdown, adaptation drift | ATF service; run adaptations; check cooler flow |

| Hybrid hesitation/jerk on start | HV battery low, inverter temp/derate | Scan hybrid controller; check temps/SoC; run tests |

| DTCs for speed sensors | Sensor/wiring fault, TCU issue | Pin-out tests; scope signals; repair wiring/sensor |

Explore More Mercedes Transmission Issues

For a deeper dive into gearbox problems slipping into Neutral, delayed/harsh shifts, “Not in P” warnings, and hybrid faults visit our hub: Mercedes Transmission Issues – Causes and Fixes. You’ll find grouped case studies, step-by-step diagnostics, symptom–cause–fix tables, and prevention tips to resolve shifting issues quickly and confidently.

DIY vs Professional

| Task | DIY-Friendly | Pro Recommended | Notes |

|---|---|---|---|

| Read OBD codes, basic clear | OK | Generic readers help, but OE data is better | |

| ATF level/condition visual check | OK | Only if you know the correct temp-based procedure | |

| Software checks, adaptations (XENTRY) | OK | Requires OE tool and strict prerequisites | |

| HV safety shutdown / inverter checks | OK | HV certification needed | |

| Transmission removal & teardown | OK | Specialist job with fixtures & WIS specs | |

| Input shaft / start-off clutch replacement | OK | Precision assembly; cleanliness critical |

Preventive Maintenance & Owner Tips

- – ATF & filter at sensible intervals (many workshops target 60–80k km / 4–5 years even if “lifetime”).

- – Keep cooling system healthy; overheated ATF shortens clutch life.

- – Avoid repeated launches on low HV SoC; torque blending can stress the start-off clutch.

- – After any module/software update, complete adaptations per XENTRY so clutch fills/overlaps relearn correctly.

- – Fix minor jerks or delays early they’re warnings, not quirks.

Table: Repair Timeline & Cost Drivers

| Operation | Typical Time | What Affects Cost |

|---|---|---|

| Full diagnosis + road logs | 1.0–2.0 h | Access to OE data, replication time |

| Transmission R&R + teardown | 6–10 h | Model packaging, corrosion, seized fasteners |

| Input shaft + start-off clutch | 2–4 h (within teardown) | Parts availability, machining needs |

| Reassembly, fill, level set | 1–2 h | ATF temp control, leaks, seals |

| Adaptations + validation drive | 0.5–1.0 h | Ambient temp, traffic, learning cycles |

Actual labor varies by market; use as a planning guide.

Potential Software & Integration Factors

- – TCU/EGS and Hybrid Controller must agree on torque requests. Mismatched software after module replacement or incomplete coding can mimic hardware faults.

- – If hardware is sound but symptoms persist, check for software updates, coding consistency, and calibration status (e.g., clutch/adaptation routines).

FAQs: Mercedes Hybrid Transmission Malfunction

1) My E300 Hybrid stopped and shows “Transmission Malfunction.” Can I restart and drive?

If the car lost drive, don’t force it. You may cause additional damage. Get a diagnosis and tow if needed especially if speeds read 0 rpm under throttle.

2) Do all-zero speed readings always mean a broken shaft?

No, but it’s highly suspicious for mechanical decoupling (start-off clutch or splines). Rule out sensor/wiring first if you have relevant DTCs, then consider mechanical teardown.

3) Will a software update fix a hybrid transmission malfunction?

Software helps when the issue is logic/adaptation. It won’t fix a broken input shaft or burned clutch. Verify with live data and physical inspection.

4) What is the “start-off clutch”?

It’s the clutch that engages initial drive and manages torque hand-off between the engine/e-machine and gearbox. If it fails, the car may not move or may jerk harshly.

5) Can low hybrid battery state of charge cause transmission faults?

Low SoC can reduce available e-torque, causing odd drivability, but it won’t make all transmission speeds stay at 0 rpm under throttle. Treat SoC issues separately.

6) How often should I service the transmission on a hybrid?

Many specialists recommend ATF service every 60–80k km (or 4–5 years). Heat, towing, and city traffic justify shorter intervals.

7) Is it safe to DIY an E300 Hybrid transmission repair?

No, due to HV risks and precision assembly. DIY is fine for basic scanning and visual checks; leave mechanical teardown and HV work to certified techs.

Conclusion

Hybrid transmission faults demand data-driven diagnosis. In this E300 Hybrid, all speeds stuck at 0 rpm pointed to hard mechanical failure confirmed as a damaged input shaft and start-off clutch. Replacing the failed parts, restoring proper assembly, and validating with live data returned the car to full health. Use the workflow here—scan → live data → prerequisites → electrical vs mechanical → WIS-guided repair → validate to fix the problem once, the right way.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: September 2025

Leave a Reply