Table of Contents

Problem Starting Car: Mercedes-Benz CLA 45 ; Full Diagnostic Case Study

When a Mercedes-AMG CLA 45 (W118) refuses to start, the cause can range from a simple sensor fault to a major control unit failure. In this real-world case, we’ll explore how a “Problem Starting Car” complaint was diagnosed and resolved in a CLA 45 equipped with the M139 engine one of Mercedes-AMG’s most advanced power units.

Through this case study, you’ll see how systematic diagnostics and ECU analysis led to identifying a defective Engine Control Unit (ME) as the root cause.

Case Study Overview

Vehicle: Mercedes-Benz CLA 45 (W118)

Engine: M139 2.0 L Turbocharged AMG

Complaint:

- – Engine does not start.

- – Oil level indicator appears on the instrument cluster.

This issue rendered the vehicle completely inoperative and required an advanced diagnostic approach using Mercedes STAR/XENTRY tools.

Diagnostic Process: Step-by-Step Investigation

A problem starting car scenario in a modern AMG engine requires methodical electrical and pressure testing before replacing any parts.

Below is the complete diagnostic sequence performed by the workshop.

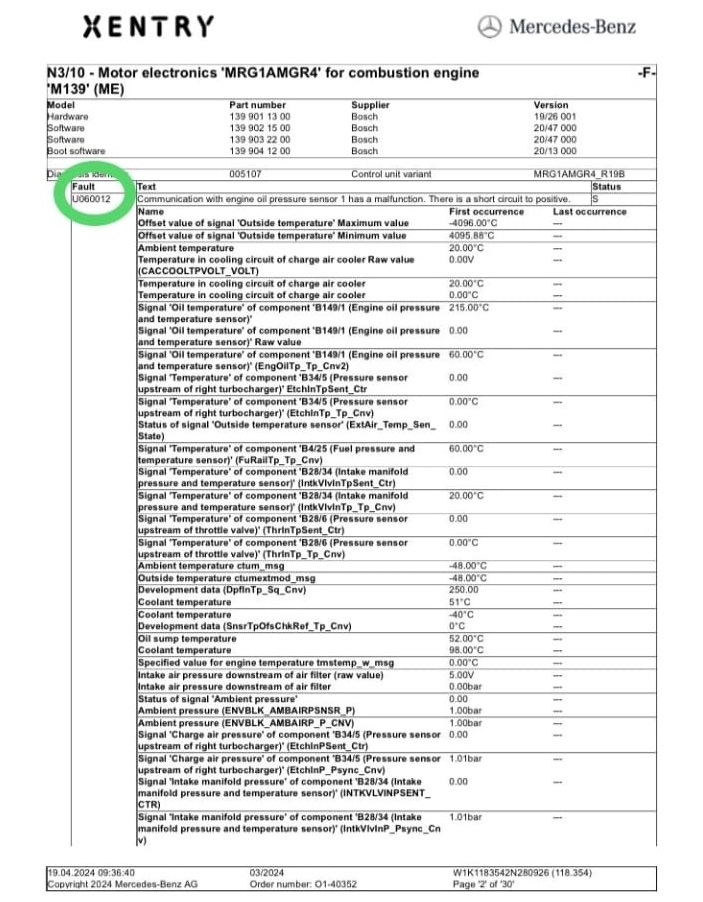

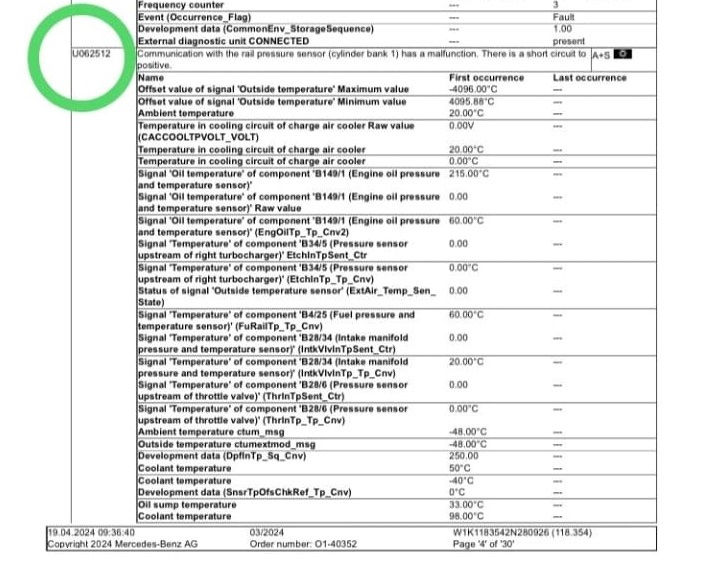

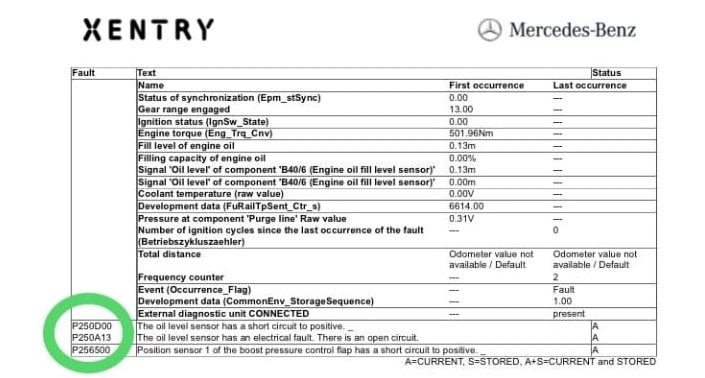

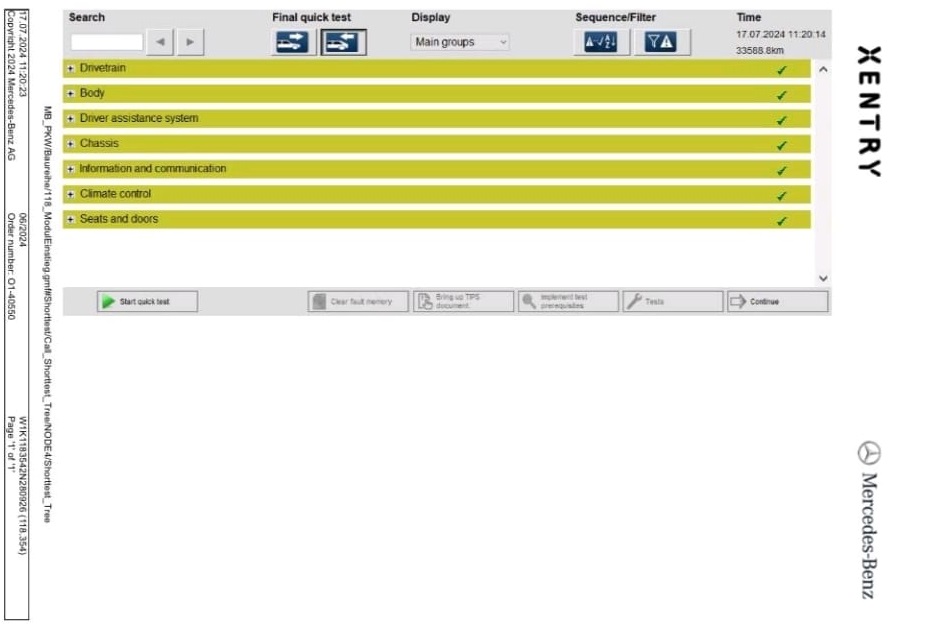

1. Short Test : Fault Code Retrieval

A complete short test was conducted via the Engine Control Unit (ME) to identify any stored or active fault codes.

Finding:

Fault codes indicated internal malfunction within the ECU (ME-SFI 2.0), suggesting potential communication or processing errors.

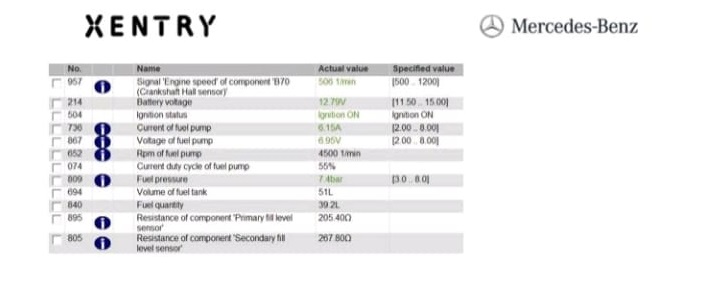

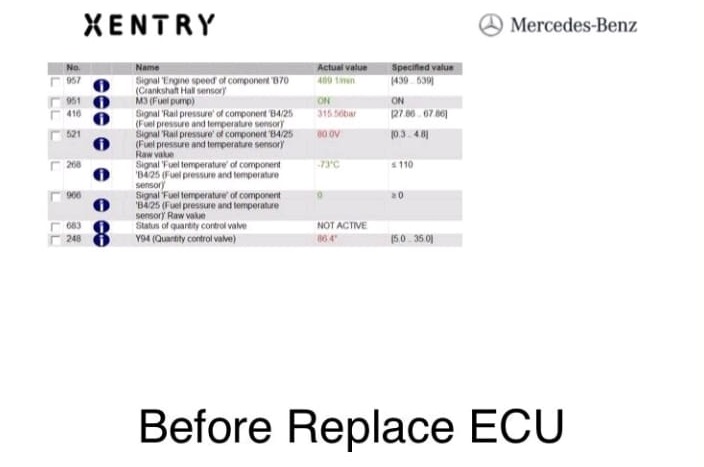

2. Fuel Pump Actual Value Check

The low-pressure and high-pressure fuel pumps were tested to confirm delivery capability.

| Parameter | Expected Range | Observed Value | Result |

|---|---|---|---|

| Low-pressure pump | 4.0 – 6.0 bar | OK | OK |

| High-pressure pump | 40 – 120 bar during cranking | Fluctuating / unstable | Irregular pressure |

The high-pressure control values were inconsistent, indicating an electronic control or signal issue rather than mechanical pump failure.

3. Voltage Check : Rail Pressure Sensor (B4/25)

The rail pressure sensor, located on the fuel rail, was tested for correct voltage output.

| Test Point | Expected Voltage | Measured Voltage | Observation |

|---|---|---|---|

| Signal Line | 0.5 – 4.5 V | Irregular / nonlinear | Abnormal readings |

This suggested that the sensor data reaching the ECU was corrupted or not being interpreted correctly.

4. Continuity Test : ECU to Rail Pressure Sensor

To rule out wiring issues, continuity between the ECU and sensor connector (B4/25) was verified.

Result:

- – Partial continuity loss detected.

- – Electrical resistance higher than specification.

- – Signal interference confirmed on one of the sensor lines.

This proved the issue was not mechanical, but electronic originating from the ECU’s internal circuits.

Workshop Findings

After correlating all results, the workshop established the following key points:

| Diagnostic Area | Finding | Conclusion |

|---|---|---|

| ECU fault code | Internal malfunction | ECU processing failure |

| High-pressure control | Unstable readings | Faulty ECU signal output |

| Sensor voltage | Incorrect voltage response | ECU reference line affected |

| Continuity check | Interrupted link ECU ↔ B4/25 | Internal ECU circuit damage |

The Engine Control Unit (ME) was confirmed defective.

Repair & Rectification

Step 1: Replace Engine Control Unit (ME)

A new, genuine Mercedes-Benz Engine Control Unit was installed.

The replacement included:

- – Coding and programming via XENTRY Diagnostic.

- – Initialization of high-pressure fuel control adaptation.

- – Verification of sensor communication integrity.

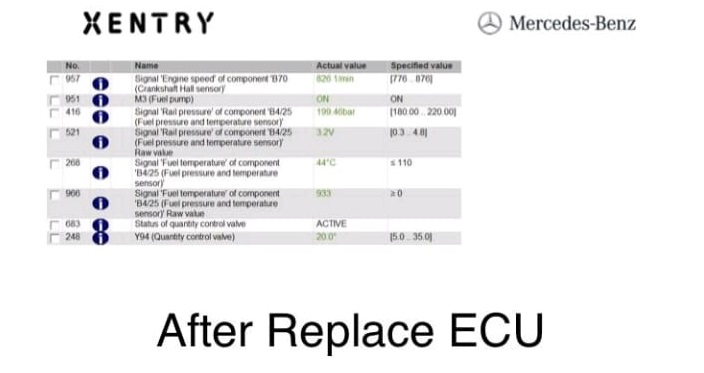

Step 2: Verification Tests

After installation, all actual values were rechecked.

| Parameter | Before | After |

|---|---|---|

| High-pressure control | Unstable | Stable and within range |

| Rail pressure voltage | Erratic | Linear 0.5 – 4.5 V |

| ECU communication | Intermittent | Continuous |

| Engine start test | Failed | Successful |

The vehicle started instantly, idled smoothly, and no fault codes reappeared.

Key Takeaways

| Insight | Explanation |

|---|---|

| Thorough diagnostics save time and cost | Skipping tests can lead to unnecessary part replacements. |

| ECU is the brain of the engine | Controls ignition, fuel pressure, and communication with all sensors. |

| High-pressure fuel systems require precision | Even slight signal corruption prevents proper start. |

| Always verify wiring and continuity | Electrical faults can mimic sensor failures. |

| Use genuine ECUs only | Aftermarket control units may not meet AMG engine tolerances. |

Why the Engine Control Unit Failed

The ECU (ME-SFI 2.0) in the M139 engine operates under high thermal and electrical loads.

Potential contributing factors:

- – Heat exposure near turbocharger assembly.

- – Electrical surges from auxiliary systems.

- – Internal solder joint failure or water ingress.

Because the ECU processes rail pressure and injector timing, even a minor circuit defect can disable the entire start sequence.

Lessons for Technicians

| Best Practice | Benefit |

|---|---|

| Perform short tests before physical inspection | Speeds up fault isolation |

| Measure both actual and reference voltages | Confirms sensor logic errors |

| Use STAR/XENTRY for ECU adaptation | Prevents future calibration issues |

| Document pre- and post-repair values | Builds traceability and customer trust |

Case Summary

| Step | Action | Outcome |

|---|---|---|

| Diagnostic scan | Found ECU internal malfunction | Confirmed electronic fault |

| Voltage & continuity test | Detected abnormal values | Verified communication loss |

| ECU replacement | Installed & coded new ME unit | Engine started successfully |

Result: Starting problem resolved.

Root Cause: Defective Engine Control Unit (ME).

Related Diagnostic Resource

If your Mercedes is showing electrical warnings or struggling to start, explore our complete troubleshooting guides:

Mercedes Electrical Problems: Fix SAM, ECU & CAN Bus Faults; learn how to diagnose power loss, short circuits, and communication errors in control modules and wiring systems.

Mercedes No Start Issues: Causes, Fixes & Case Studies; a comprehensive guide covering electrical, fuel, and ECU-related no-start scenarios across multiple Mercedes models.

Together, these resources give you a complete diagnostic roadmap from electrical supply faults and ECU power interruptions to full no-start and communication-related issues.

FAQ: Problem Starting Car

1. Why does my Mercedes crank but not start?

It can result from low fuel pressure, sensor faults, or ECU malfunction preventing injector activation.

2. Can an ECU failure cause no-start without warning lights?

Yes, internal ECU defects can block communication while leaving the dashboard functional.

3. How to confirm if my ECU is faulty?

Check for missing reference voltages, abnormal actual values, and loss of communication with sensors via XENTRY.

4. Is ECU replacement plug-and-play?

No. It requires VIN coding, adaptation, and immobilizer synchronization by qualified technicians.

Author Bio

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last update: November 2025

Leave a Reply