Table of Contents

Why is My Mercedes Lower On One Side? A Case Study of the Mercedes-Benz GL450

A common complaint among owners of Mercedes-Benz models equipped with the AIRMATIC suspension system is the vehicle sitting lower on one side. While the AIRMATIC system delivers remarkable ride comfort and handling by adjusting suspension height and damping automatically, it can also develop faults that disrupt vehicle leveling.

In this case study, we focus on a Mercedes-Benz GL450 equipped with the M273 engine. The SUV presented with a pronounced right-side drop, triggering a suspension system check message. We’ll break down the diagnostic steps, repair process, challenges, and final resolution.

Vehicle Profile

- Model: Mercedes-Benz GL450

- Engine: M273 V8

- Complaint: Noticeable drop on the right side, AIRMATIC malfunction warning

- Diagnostic Summary: Air leak at rear connection, faulty valve block, calibration issues

Step 1: Initial Function Check & Visual Inspection

The diagnostic journey began with a function check of the AIRMATIC suspension:

- – The controls were activated to observe suspension behavior.

- – A visual inspection was conducted, focusing on the right rear side where the drop was most noticeable.

Findings:

- – The right rear suspension sagged significantly after parking.

- – Signs of an air leak were visible around the rear right connection.

Step 2: Fault Code Retrieval & Guided Tests

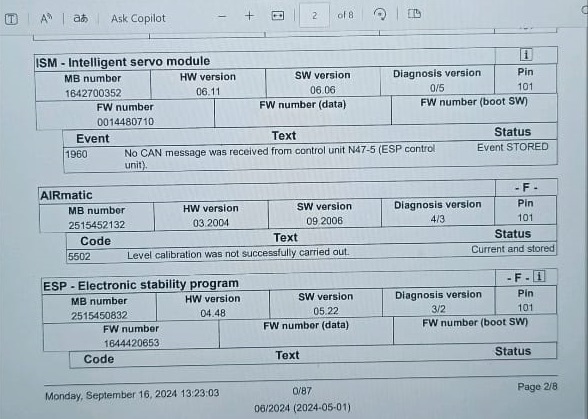

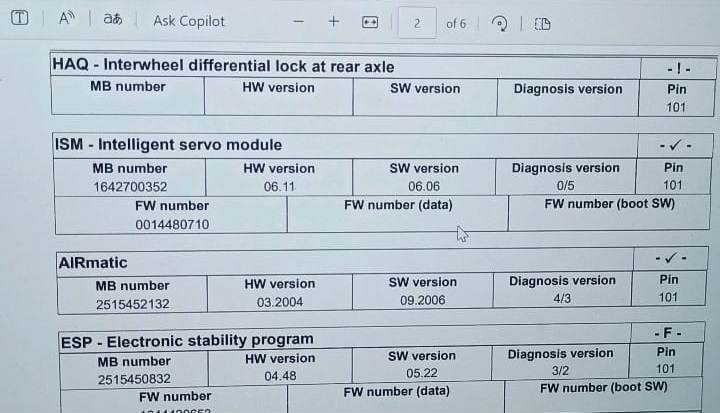

Using Mercedes-Benz Xentry diagnostics, fault codes were retrieved from the AIRMATIC control unit.

- – Multiple faults were logged, including 5502 – level calibration failure.

- – The guided test procedures suggested problems in the right rear suspension system.

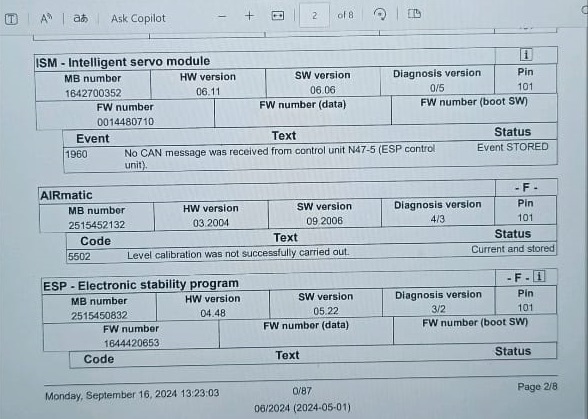

Step 3: Pneumatic Test & Leak Detection

To confirm the suspicion of air leakage, a pneumatic pressure test was carried out.

- – The test showed significant air loss from the rear right connection.

- – The right rear level control valve was also malfunctioning, failing to maintain the required air pressure.

This explained the persistent right-side sagging and inability of the system to hold vehicle height.

Step 4: Attempted Calibration & Error Code 5502

The next step was to recalibrate the suspension levels automatically.

- – Calibration attempts failed, and fault code 5502 reappeared as a current fault.

- – This fault indicated the control unit could not achieve correct height levels, confirming deeper system issues.

Step 5: Initial Component Replacement

To address the problem, the following steps were taken:

- 1. The rear right air spring connection was replaced.

- 2. An automatic calibration was attempted again.

However, challenges remained:

- – The up/down AIRMATIC switch was still not functional.

- – The system continued to log implausible fault codes.

Step 6: Manual Calibration with ROMESS Inclinometer

Since automatic calibration failed, a manual calibration was performed using a ROMESS inclinometer. This specialized tool allows precise manual setting of ride height.

Results:

- – Fault codes were temporarily cleared.

- – The up/down suspension switch became operational.

- – However, the AIRMATIC malfunction warning persisted, signaling further faults.

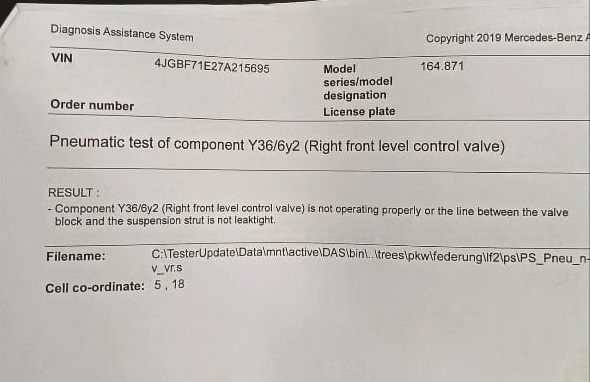

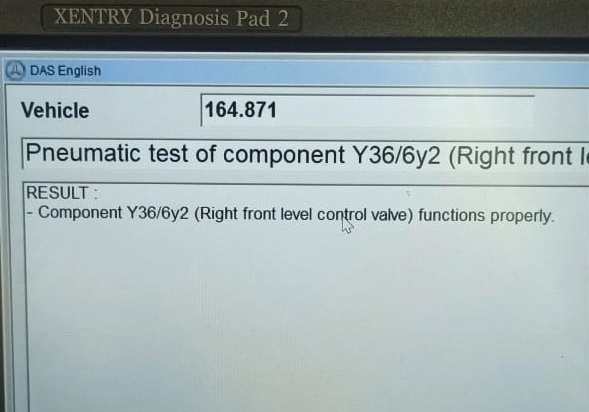

Step 7: Final Diagnosis : Valve Block Replacement

A deeper investigation pointed to the valve block a component that regulates air distribution to each suspension strut.

- – The valve block was replaced.

- – A final automatic calibration was performed.

This time:

- – Calibration succeeded.

- – All fault codes were cleared.

- – The vehicle’s suspension height was restored evenly, resolving the “Mercedes lower on one side” problem.

Symptom –> Cause –> Fix Table

| Symptom | Likely Cause | Repair Solution |

|---|---|---|

| Vehicle drops on one side after parking | Air leak in strut or connection | Inspect connections; replace faulty air spring or fitting |

| AIRMATIC malfunction warning | Valve block or level control valve failure | Replace valve block and recalibrate |

| Fault code 5502 during calibration | Incorrect level sensor readings or calibration drift | Perform manual calibration with ROMESS; replace faulty sensors if needed |

| Up/down switch non-functional | Control unit fault or unresolved calibration issue | Recalibrate, check control unit, replace if necessary |

| Repeated sagging despite repair | Internal valve leakage | Replace valve block or defective air spring |

Explore More Mercedes Suspension Issues

For a deeper dive into suspension problems such as uneven ride height, AIRMATIC malfunctions, “Stop Vehicle Too Low” warnings, and vibration faults, visit our hub: Mercedes-Benz Suspension Issues – Symptoms, Causes & Fixes. There you’ll find grouped case studies, step-by-step diagnostics, symptom, cause, fix tables, and preventive tips to keep your Mercedes riding smoothly.

Lessons from This Case

- 1. Multiple Fault Sources: Suspension faults often involve more than one component (e.g., leaks + valve block failure).

- 2. Calibration is Critical: Even after replacing hardware, proper manual or automatic calibration is necessary.

- 3. Specialized Tools Required: Tools like ROMESS inclinometers and Mercedes Xentry are essential for precise diagnosis.

- 4. Patience with Complex Systems: AIRMATIC repairs can require several iterations before the final fault is resolved.

FAQs

Q: Why does my Mercedes sit lower on one side?

A: The most common causes are air leaks in struts or connections, valve block failure, or calibration errors. Each must be diagnosed individually.

Q: Can I drive with my Mercedes lower on one side?

A: While the car may still be drivable, it is unsafe. Uneven suspension affects handling, braking, and tire wear. Immediate inspection is recommended.

Q: How much does it cost to repair this issue?

A: Costs vary:

- – Air spring replacement: $800–$1,200 per corner

- – Valve block replacement: $600–$900

- – Calibration labor: $200–$400

Q: What is fault code 5502?

A: It indicates a suspension level calibration failure, usually caused by faulty sensors, valve block issues, or unsuccessful calibration attempts.

Q: How do I prevent AIRMATIC failures?

A: Regularly inspect for air leaks, replace worn boots, and perform annual suspension diagnostics. Parking indoors also helps reduce exposure to moisture that accelerates wear.

Conclusion

The case of the Mercedes-Benz GL450 lowering on one side highlights how complex AIRMATIC suspension systems can be to diagnose and repair.

- – The initial leak at the rear connection was only part of the problem.

- – Even after replacing the air spring connection and performing manual calibration, the real culprit a faulty valve block was uncovered.

- – Replacing the valve block and recalibrating the system finally restored normal suspension function.

This case study proves that thorough diagnostics, specialized tools, and step-by-step troubleshooting are essential when addressing AIRMATIC suspension problems. With proper repairs, the GL450 regained its smooth, level ride, ensuring both comfort and safety for the driver.

Author

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last Updated: September 2025

Leave a Reply