Table of Contents

Engine Noises in Mercedes-Benz E-Class W212: Diagnosing and Fixing Abnormal Sounds

One of the most concerning issues a vehicle owner can face is engine noises. Unusual sounds from the engine bay can indicate potential mechanical failures that, if left unaddressed, may lead to costly repairs.

In this case study, we examine a Mercedes-Benz E-Class W212 equipped with the M271 engine, where a customer reported abnormal noises from the engine. This article will guide you through the diagnostic steps, root cause identification, and the corrective measures taken to resolve the issue.

Case Study: Abnormal Engine Noises in a Mercedes-Benz E-Class W212

Customer Complaint

The customer brought their Mercedes-Benz E-Class W212 to the workshop, reporting an unusual engine noise emanating from the engine compartment. The noise was persistent and noticeably louder during acceleration.

Diagnosis and Inspection

To accurately identify the cause of the engine noises, the following steps were undertaken:

1. Performed a Quick Test & Fault Code Scan

- – Connected the diagnostic scanner to check for fault codes in the engine control module (ECM).

- – No fault codes were found.

2. Checked the Engine Noise Source

- – The noise was traced to the valve cover side of the engine.

- – Further inspections confirmed that the engine noise originated from the camshaft and valve train area.

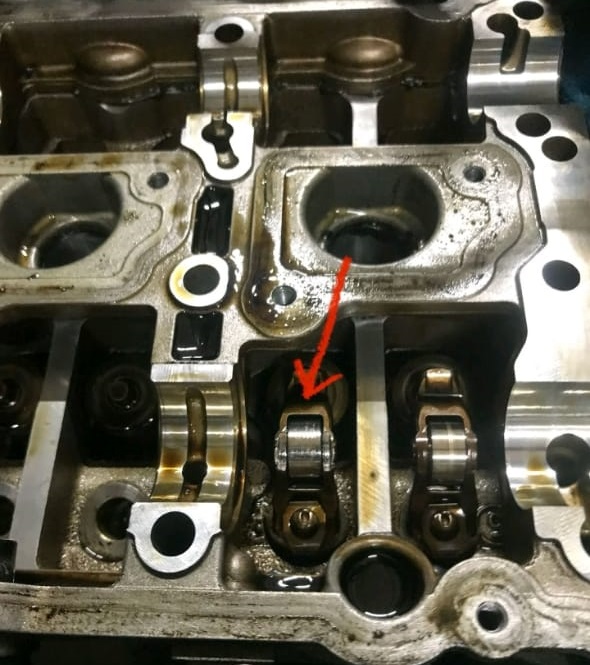

3. Removed the Valve Cover for Internal Inspection

- – The valve cover was carefully removed to expose the camshaft, rocker arms, and valve components.

- – The camshaft timing marks and cam sprocket timing marks were checked to ensure proper alignment.

- – The timing marks were found to be correct, ruling out a timing issue.

4. Inspected the Inlet Camshaft, Exhaust Camshaft, and Rocker Arms

- – Detailed examination of the inlet camshaft, exhaust camshaft, and rocker arms was performed.

- – The exhaust camshaft showed significant damage.

- – The rocker arm needle bearing on the exhaust camshaft side was found to be excessively worn out.

Root Cause Analysis

The root cause of the engine noise was determined to be:

- – Excessive wear on the rocker arm needle bearing on the exhaust camshaft side.

- – The damaged rocker arm led to abnormal friction against the exhaust camshaft, causing the persistent engine noise.

Correction and Repairs

To resolve the issue, the following corrective actions were taken:

1. Replaced the Exhaust Camshaft

- – A brand-new OEM exhaust camshaft was installed to restore proper valve operation.

2. Replaced All Rocker Arms and Rocker Arm Elements

- – Since one rocker arm was damaged, all rocker arms were replaced as a preventive measure.

- – This ensures even wear and long-term reliability of the valvetrain.

Final Checks and Testing

After completing the repairs:

- – The engine was reassembled, and a final engine noise check was performed.

- – The engine noise was no longer present, confirming a successful repair.

- – The vehicle was test-driven to ensure smooth performance and validate that no further issues existed.

The Worst Engine Noises That You Should Never Ignore

Certain engine noises indicate serious underlying mechanical problems that require immediate attention. Ignoring these sounds can lead to catastrophic engine failure and expensive repairs. Here are the top engine noises that should never be ignored:

- Knocking or Pinging Sounds – Usually caused by pre-ignition or detonation, this can lead to severe engine damage if left unchecked.

- Tapping or Clicking Sounds – Often linked to worn lifters, low oil levels, or issues with the valve train components.

- Grinding or Screeching Sounds – Can be caused by a failing timing chain, bad bearings, or belt-related problems.

- Hissing or Sizzling Sounds – Indicates potential overheating or fluid leaks in the cooling or exhaust system.

- Loud Banging or Backfiring – Could be due to misfiring spark plugs, ignition timing issues, or a malfunctioning fuel system.

If you notice any of these noises, it is essential to have your vehicle inspected by a qualified technician as soon as possible.

Engine Knocking Reasons

Engine knocking is a common and concerning engine noise that may indicate severe internal issues. The main reasons for engine knocking include:

- Low-Quality or Incorrect Fuel – Using a lower octane rating than recommended can cause pre-ignition, leading to knocking.

- Carbon Build-Up – Excess carbon deposits in the combustion chamber can increase compression and cause detonation.

- Incorrect Ignition Timing – If the timing is advanced too far, the air-fuel mixture may ignite prematurely, causing knocking.

- Lean Air-Fuel Mixture – If the engine runs too lean, the combustion temperature rises, increasing the likelihood of knocking.

- Worn Rod Bearings – Excessive wear in the rod bearings can cause knocking due to increased clearance between moving parts.

- Faulty Knock Sensor – A malfunctioning knock sensor may fail to detect detonation and adjust the ignition timing accordingly.

If you experience persistent knocking sounds, it is crucial to diagnose and fix the underlying problem to prevent severe engine damage.

Preventive Measures to Avoid Engine Noises in the M271 Engine

To prevent similar engine noises in the future, vehicle owners should:

1. Perform Regular Oil Changes

- – Using high-quality engine oil and maintaining proper oil change intervals can reduce wear on valvetrain components.

2. Monitor Unusual Noises Early

- – Addressing minor engine noises early can prevent major component failures.

3. Inspect and Replace Wear Items Proactively

- – If a technician identifies wear on rocker arms, camshafts, or related components, replacing them before failure occurs can save on costly repairs.

Conclusion

Abnormal engine noises in the Mercedes-Benz E-Class W212 equipped with the M271 engine can indicate serious valvetrain issues. In this case, a worn-out rocker arm needle bearing led to exhaust camshaft damage.

Through a systematic diagnosis and proper component replacement, the issue was resolved effectively. Vehicle owners should remain vigilant for unusual engine noises and seek professional inspection promptly to avoid severe engine damage.

Leave a Reply