Table of Contents

“48V Battery – See Owner’s Manual” Warning in Mercedes C200 (W205): Full Diagnostic & Repair Case

When your Mercedes C200 displays a “48V Battery See Owners Manual” warning, it means that your vehicle’s mild-hybrid power network which manages both 12V and 48V systems has detected a fault condition in the high-voltage (48V) circuit.

Unlike a conventional low-voltage battery issue, this one can affect the Integrated Starter Generator (ISG), energy recovery, and even the engine start sequence. Ignoring it can cause limp mode activation or loss of Start/Stop functionality.

This case study from our workshop explains exactly how a Mercedes-Benz (W205) equipped with M264 Engine was diagnosed and repaired after displaying this warning.

Case Study: Mercedes-Benz C200 (W205), 48V Battery Warning

Customer Complaint

Dashboard displayed “48V Battery See Owners Manual”, but the car still drove normally.

The customer noticed that Start/Stop stopped working and the A symbol remained crossed out.

Vehicle Info:

- – Model: Mercedes-Benz C200 W205 (M264 Engine)

- – System: 48V Mild Hybrid (EQ Boost)

- – Mileage: 63,000 km

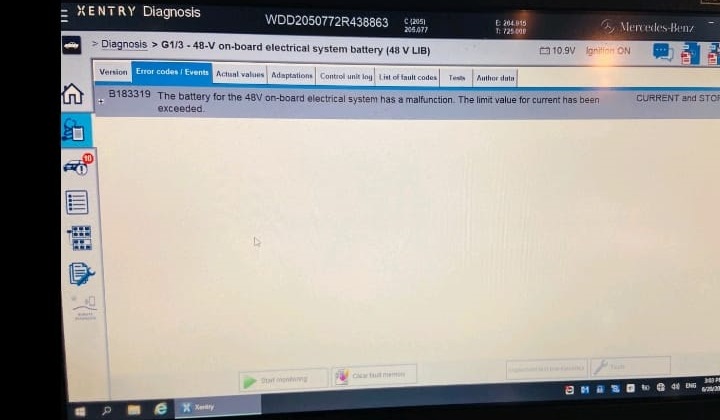

Step 1: Initial Diagnostic Scan (XENTRY)

Using Mercedes-Benz XENTRY Diagnostics, the technician performed a complete scan.

The following fault code was retrieved:

- – B183319 – G1/3 48V On-Board Electrical System Battery (LIB): Malfunction – Current limit value exceeded.

System Context:

The 48V battery (LIB) communicates with the Battery Management Control Unit (BMS) via LIN and CAN networks. The error code suggested an overcurrent or communication fault inside the LIB module.

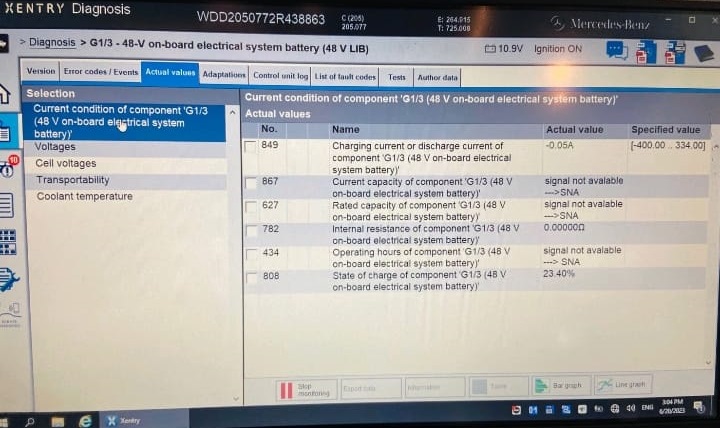

Step 2: Live Data and Signal Analysis

The diagnostic tool showed two key data signals missing:

- – Current Capacity (Ah) → Not available

- – Rated Capacity (Ah) → Not available

Interpretation:

These missing values indicated a communication breakdown inside the 48V lithium-ion battery pack, preventing the BMS from reading internal sensor data.

Without this data, the BMS flags the system as unstable triggering the “48V Battery” warning and disabling ISG-related features.

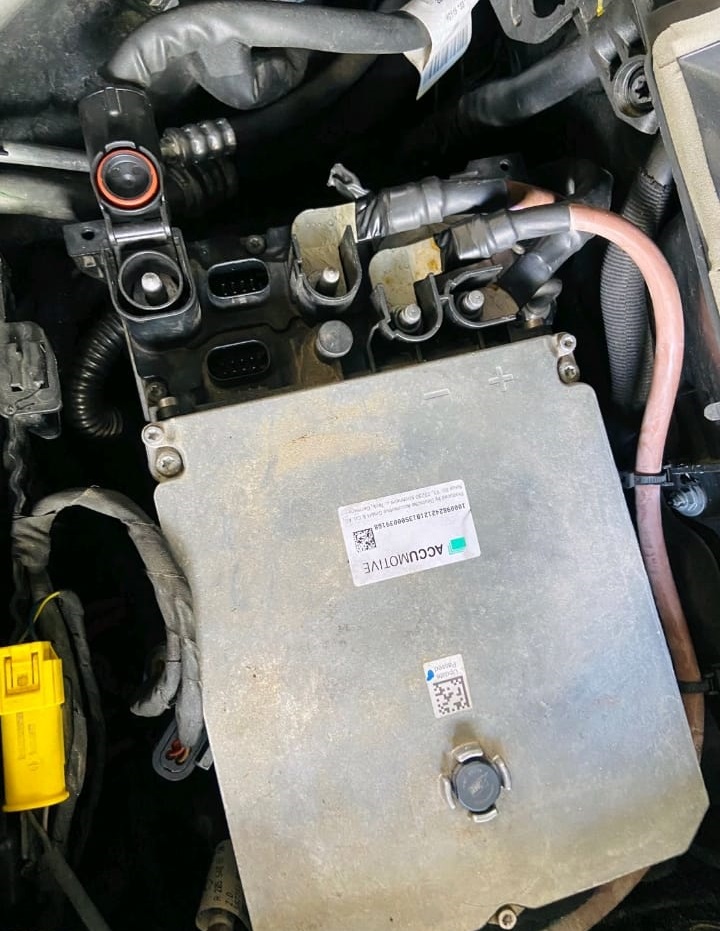

Step 3: Visual & Physical Inspection

To verify the hardware, the technician removed the 48V battery module (G1/3), typically located beneath the rear floor or luggage compartment in the W205.

Findings:

- – Evidence of water ingress inside the battery housing.

- – Moisture corrosion visible around the cell control board and connector pins.

- – No external wiring faults detected on the power harness or CAN/LIN connectors.

This moisture likely entered through a failed trunk seal or blocked drain, a known issue in some EQ Boost models.

Step 4: Repair Process

- 1. Battery Disassembly: The technician carefully opened the 48V LIB housing to inspect the internal PCB and cell connections.

- 2. Cleaning Process: All affected areas were cleaned using isopropyl alcohol and dried with low-pressure air to eliminate moisture traces.

- 3. Terminal Reconditioning: Corroded contacts were re-pinned and resealed with dielectric grease.

- 4. Reassembly: The 48V LIB was resealed with silicone gasket material to prevent future leaks.

- 5. System Reset: After reinstalling, the BMS was reset, and DTCs were cleared using XENTRY.

Step 5: Verification & Functional Testing

| Parameter | Before Repair | After Repair |

|---|---|---|

| 48V battery voltage | 44.2 V fluctuating | 47.9 V stable |

| BMS current capacity signal | Not available | Active (valid) |

| Rated capacity signal | Not available | Active (valid) |

| Start/Stop function | Disabled | Operational |

| Warning message | Present | Cleared |

Result: The “48V Battery See Owner’s Manual” warning disappeared, Start/Stop was restored, and no fault codes reappeared after a 20-minute test drive.

Step 6: Root Cause Analysis

| Component | Fault Description | Impact |

|---|---|---|

| 48V LIB housing | Water ingress through vent seal | Corroded PCB and lost capacity signal |

| BMS signal line | Corrosion on internal connector | Missing rated capacity data |

| Vehicle drains | Clogged trunk drainage | Allowed condensation buildup |

Final Diagnosis:

Water contamination inside the 48V lithium-ion battery module (LIB) caused internal communication errors with the BMS, triggering the system warning and disabling hybrid functionality.

Step 7: Preventive Measures

- – Inspect trunk seals and rear drain lines annually.

- – Avoid pressure washing near trunk vents.

- – Keep BMS connectors dry and sealed with dielectric grease.

- – Run a periodic XENTRY scan to check the isolation resistance and 48V system voltage every 10,000 km.

Understanding the Mercedes 48V System

The 48V mild-hybrid system in models like the W205 C200 is part of Mercedes’ EQ Boost architecture, integrating several critical components:

| Component | Function |

|---|---|

| 48V Lithium-ion Battery (LIB) | Stores high-voltage energy for ISG, compressors, and suspension. |

| Integrated Starter Generator (ISG) | Replaces alternator; provides torque assist and regenerative braking. |

| DC/DC Converter | Converts 48V power to 12V for auxiliary systems. |

| BMS (Battery Management System) | Monitors battery temperature, voltage, and current data. |

A malfunction in any part especially the LIB or converter can cause hybrid shutdown or limp mode.

Technician Insights

- – The 48V and 12V systems are interdependent. A 48V failure can trigger secondary errors in SAM or ESP modules.

- – Never jump-start directly via the 48V circuit. Always use the 12V battery terminals.

- – When replacing or cleaning a 48V LIB, follow high-voltage safety standards these packs store significant energy.

Related Diagnostic Resource

If your Mercedes displays voltage, LIN, or module-communication faults, explore this comprehensive guide:

Mercedes Electrical Problems: Fix SAM, ECU & CAN Bus Faults

A complete technical hub for diagnosing voltage drops, network communication losses, and module synchronization errors across Mercedes-Benz models.

This resource complements 48V system diagnostics by explaining how control-module power faults and CAN/LIN disruptions can cascade into hybrid battery warnings.

Conclusion

This Mercedes-Benz C200 W205 case demonstrates how a simple dashboard message “48V Battery See Owners Manual” can trace back to a physical water-ingress issue inside the 48V lithium-ion module.

Through systematic diagnostics, voltage testing, and careful component reconditioning, the system was restored to full function.

Maintaining dry seals, clean drains, and proper voltage management ensures your EQ Boost system performs reliably for years.

Author Bio

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last update: November 2025

Leave a Reply