Table of Contents

AdBlue System Malfunction in Mercedes-Benz A-Class (W177) – Diagnosis and Fix

Modern Mercedes-Benz diesel models rely on precise AdBlue dosing to meet strict Euro 6 emission standards. When the AdBlue System Malfunction message appears, it means the Selective Catalytic Reduction (SCR) system isn’t working correctly and ignoring it can eventually lead to engine start restrictions or non-compliance with emission regulations.

This case study explains how our workshop diagnosed and repaired a Mercedes-Benz A-Class (W177) with the OM654 engine, which showed a persistent AdBlue malfunction warning despite recent fluid refilling.

Customer Complaint

- Model: Mercedes-Benz A-Class W177

- Engine: OM654 diesel

- Symptom: “AdBlue System Malfunction” displayed on the instrument cluster even after refilling AdBlue.

- Condition: Vehicle remained driveable, but the customer feared eventual start restriction.

Step 1: Initial Diagnostic Process

Action:

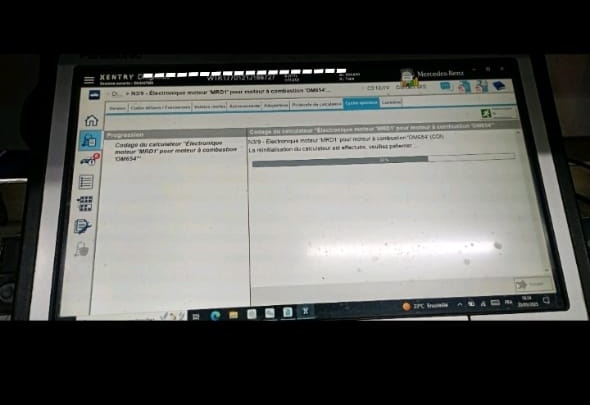

Performed a quick test using the Mercedes-Benz XENTRY diagnostic system.

Findings:

- – Stored fault codes in the engine control unit (ECU) confirmed an AdBlue system malfunction.

- – Live data analysis revealed abnormal dosing patterns inconsistent injector behavior during SCR activation.

Interpretation:

The irregular dosing pattern suggested a mechanical blockage or electrical failure in the AdBlue dosing circuit.

Step 2: Guided Testing with XENTRY

Following the guided test plan, we inspected all SCR components electronically and mechanically.

Focus Areas:

- – AdBlue dosing valve operation

- – Pressure buildup in AdBlue lines

- – Electrical continuity and feedback from the SCR control circuit

Step 3: Root Cause Identification

Inspection Result:

After removing the AdBlue dosing valve, a mechanical blockage was found inside the nozzle.

Cause:

Crystallized AdBlue residue likely due to low-quality urea solution or infrequent system activation during short drives.

Effect:

Blocked dosing valve prevented proper urea injection into the exhaust system, causing SCR malfunction and triggering the dashboard warning.

Step 4: Repair Solution

Repair Action:

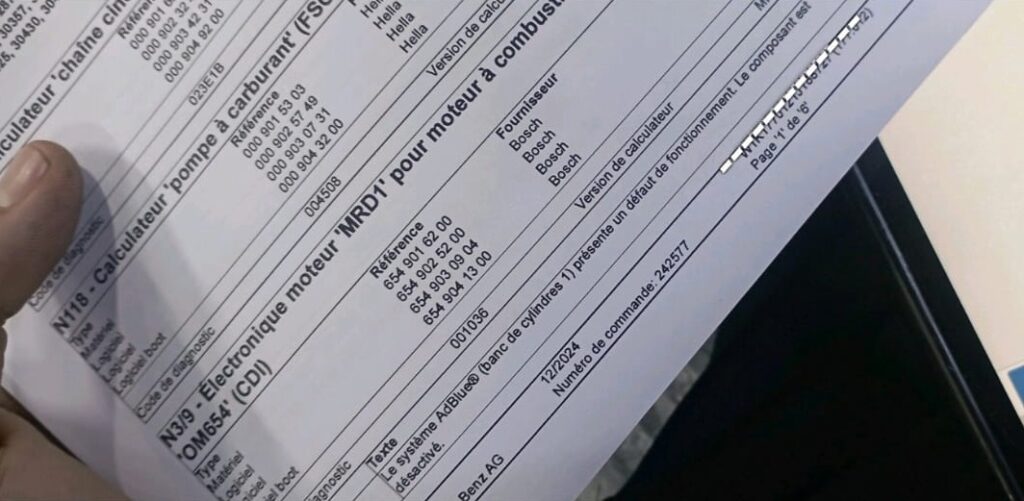

Replaced the AdBlue dosing valve with a genuine OEM Mercedes-Benz part to ensure long-term reliability.

Replacement Steps:

- 1. Disconnect vehicle battery.

- 2. Access AdBlue tank and dosing valve area (under rear floor).

- 3. Remove the blocked valve and inspect surrounding lines for crystallization or leaks.

- 4. Install new dosing valve and reconnect harness.

- 5. Restore power and verify all electrical connections.

Step 5: AdBlue System Reset & Adaptation

After replacing the component, the AdBlue system must be reset to clear previous fault data.

Using XENTRY:

- – Cleared stored fault codes from the ECU.

- – Reset AdBlue adaptation values.

- – Performed functional test of the new dosing valve to confirm proper communication with the SCR module.

After reset, the dashboard warning cleared automatically and system readings returned to normal.

Step 6: Final Verification

Performed a complete post-repair validation:

- – No fault codes remaining in ECU.

- – Stable AdBlue pressure and dosing frequency within factory specification.

- – Instrument cluster free of warnings.

Result: The AdBlue System Malfunction was fully resolved, and the Mercedes A-Class returned to normal operation.

Technician Insight

The root cause of this fault was AdBlue crystallization inside the dosing valve a problem increasingly seen in modern diesel models with low annual mileage.

Preventive maintenance and high-quality AdBlue fluid significantly reduce such issues.

Tip: Always perform a system reset after replacing any SCR component, or the ECU will continue to log outdated fault codes.

Common Causes of AdBlue System Malfunction

| Cause | Description | Recommended Fix |

|---|---|---|

| Crystallized AdBlue | Deposits blocking dosing valve | Replace dosing valve, clean lines |

| Contaminated fluid | Water or impurities in AdBlue tank | Drain and refill with OEM-approved AdBlue |

| Defective NOx sensor | Incorrect emissions readings | Replace faulty sensor |

| Electrical fault | Damaged wiring or poor connector contact | Repair wiring harness |

| Pump malfunction | Pressure buildup failure | Test and replace AdBlue pump |

Frequently Asked Questions

1. What causes an AdBlue System Malfunction in Mercedes-Benz?

Usually caused by crystallization, low-quality fluid, or a blocked dosing valve. Electrical or sensor faults may also contribute.

2. Can I drive with this warning?

Temporarily yes, but Mercedes will initiate a start restriction countdown if the fault persists. Diagnose early to avoid no-start conditions.

3. Do I need to reset the AdBlue system after repair?

Yes, resetting via XENTRY clears fault codes and reinitializes SCR dosing logic. Skipping this step may leave the warning active.

4. How much does replacement cost?

AdBlue dosing valve replacement typically costs €300–€600, depending on labor and part sourcing.

Related Reading

For a complete overview of all Mercedes AdBlue issues, including system faults, resets, and real case studies, visit our dedicated hub:

Mercedes AdBlue Problems: Causes, Fixes & Reset Guide

This hub covers:

- – AdBlue System Fault See Owner’s Manual

- – AdBlue Reset Mercedes (P13E400, P13DF00)

- – Common SCR failures and maintenance practices

Conclusion

In this case, replacing a blocked AdBlue dosing valve and performing a proper reset resolved the malfunction entirely. Following a structured diagnostic process and using OEM parts ensures long-term reliability and emission compliance.

For technicians and owners alike, timely maintenance and quality AdBlue fluid are key to preventing similar SCR system faults.

Author Bio

Mercedes Expert is an automotive technical trainer and Mercedes-Benz diagnostics expert with extensive hands-on experience in XENTRY, DTS Monaco, and advanced system troubleshooting. He specializes in transforming real workshop case studies into structured learning content to help technicians, car owners, and enthusiasts understand complex vehicle systems.

Last update: October 2025

Leave a Reply