Table of Contents

AIRMATIC Malfunction in Mercedes-Benz E-Class W213: A Diagnostic Case Study

The AIRMATIC suspension system in the Mercedes-Benz E Class W213 is one of the features that defines the luxury driving experience. By automatically adjusting ride height and damping characteristics, it ensures optimal comfort, handling, and stability across a wide range of driving conditions.

But when the dreaded “AIRMATIC malfunction” message appears on the dashboard, it’s a clear sign that something is wrong. Ignoring this warning can lead to poor ride quality, compromised safety, and costly repairs.

In this case study, we’ll explore a real-world example of an AIRMATIC malfunction in a Mercedes-Benz E-Class W213, breaking down the diagnostic process, identifying the fault, and detailing the steps taken to restore the suspension system.

Customer Complaint

- Vehicle: Mercedes-Benz E-Class W213

- Issue: “AIRMATIC malfunction” warning displayed on the dashboard.

The customer expressed concern that the suspension system might fail completely, as the E-Class relies heavily on AIRMATIC to deliver the smooth ride expected of a Mercedes.

Diagnostic Process

Step 1: Complaint Verification

The first step was to confirm the issue. With the ignition on, the “AIRMATIC malfunction” message was clearly visible on the cluster.

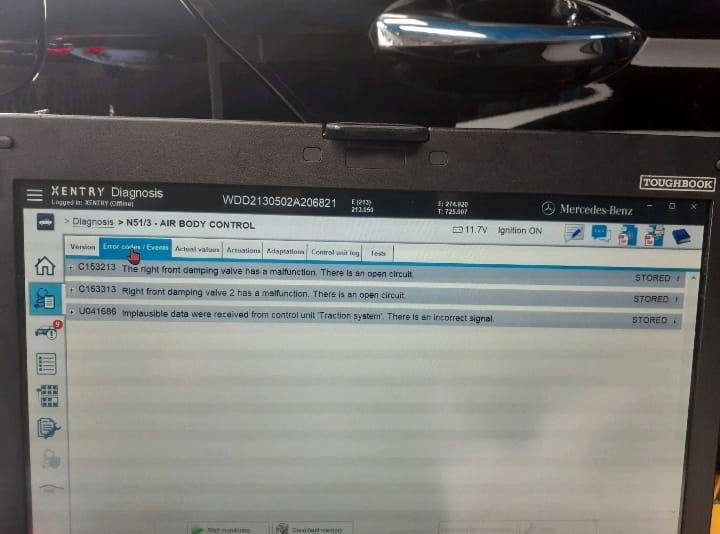

Step 2: Xentry Diagnostic Scan

The vehicle was connected to Xentry Diagnostics, Mercedes-Benz’s official diagnostic tool. Several fault codes were retrieved from the N51/3 Air Body Control Unit:

- C153213: Right front damping valve malfunction – open circuit.

- C153313: Right front damping valve 2 malfunction – open circuit.

- U041686: Implausible data received from the traction system control unit – incorrect signal.

These codes suggested a problem specifically affecting the right front damping valves.

Step 3: Fault Code Analysis

- – C153213 & C153313 → Both highlighted open circuits in the right front damping valves. Likely causes included damaged wiring, faulty connectors, or defective valves.

- – U041686 → Showed implausible data coming from the traction control system. This was likely a secondary fault, triggered by the malfunctioning damping valves.

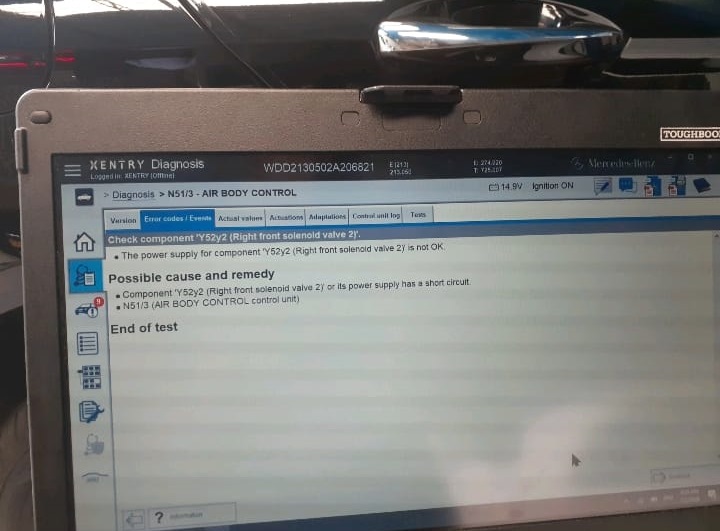

Step 4: Step-by-Step Diagnostic Checks

1. Voltage & Wiring Check

- – The connectors leading to the right front damping valves were tested.

- – Voltage supply was within expected range, ruling out power issues.

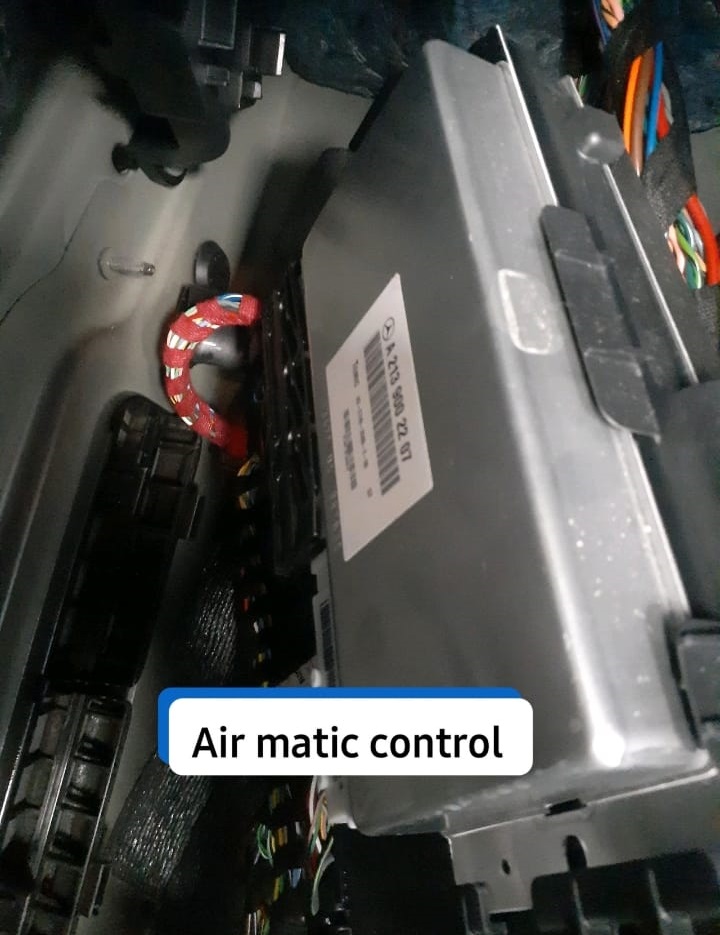

2. AIRMATIC Control Unit Inspection

- – Physical inspection of the control unit and connectors showed no corrosion or damage.

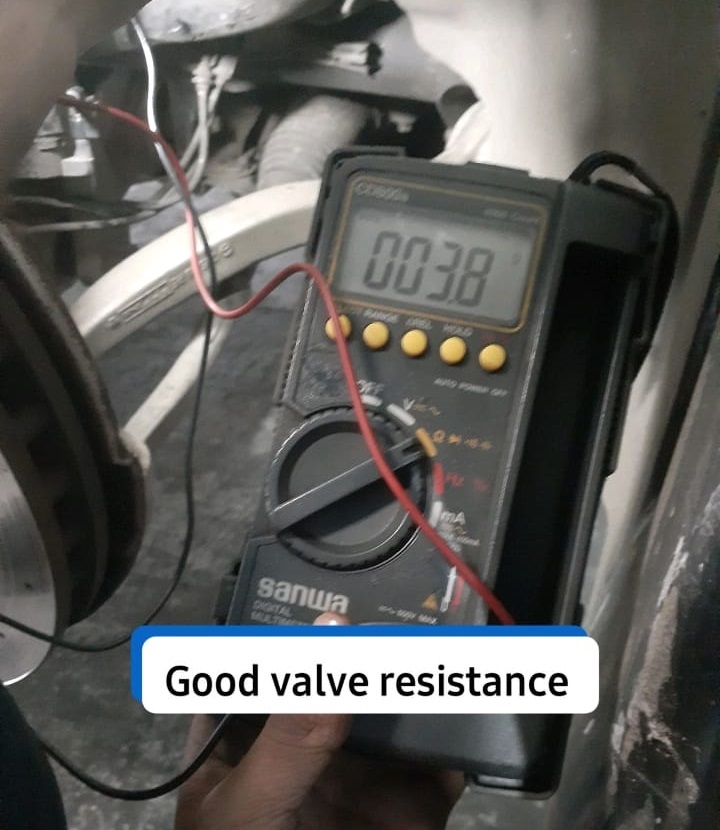

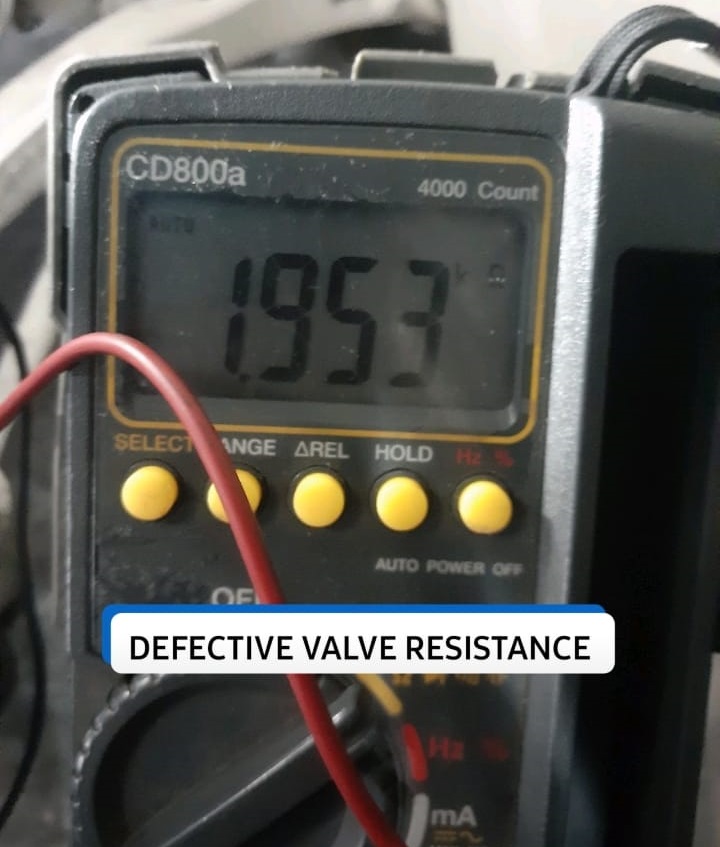

3. Resistance Check of Damping Valves

- – Resistance values were measured at the damping valves.

- – One valve showed normal resistance, but damping valve 2 recorded abnormally high resistance, confirming an internal fault.

Resolution & Repair Process

With the diagnosis complete, the repair process was carried out:

- .1. Replacement of Faulty Damping Valve

- – The defective right front damping valve 2 was removed and replaced with a new OEM Mercedes-Benz part.

- 2. System Reset & Calibration

- – Fault codes were cleared using Xentry.

- – The AIRMATIC system was recalibrated to ensure proper function of the new valve.

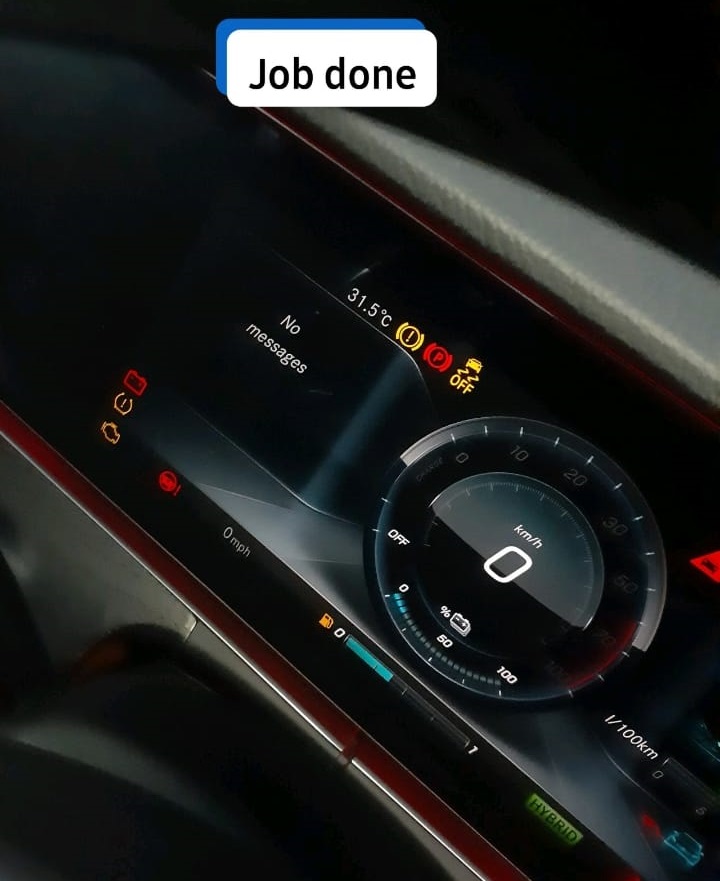

- 3. Test Drive & Quality Check

- – After replacement, the vehicle was test driven.

- – No new fault codes appeared, and the “AIRMATIC malfunction” warning was gone.

- – Suspension operated smoothly in all modes, confirming the fix.

Symptom –> Cause –> Fix Table

| Symptom | Possible Cause | Repair Solution |

|---|---|---|

| “AIRMATIC malfunction” warning on dashboard | Faulty damping valve, wiring issue, or control unit error | Diagnose with Xentry, replace defective valve, recalibrate |

| Vehicle rides rough or bouncy | Failed damping valves or struts | Inspect damping system, replace faulty valve/strut |

| Leaning to one side | Air leak in spring or valve block | Perform leak test, replace air spring or valve block |

| Suspension fails to raise | Compressor fault or electrical failure | Replace compressor, check relay and power supply |

| Frequent compressor activity | System leak or worn valve | Inspect hoses, repair leaks, replace faulty components |

Explore More Mercedes Suspension Issues

For a deeper dive into suspension problems such as uneven ride height, AIRMATIC malfunctions, “Stop Vehicle Too Low” warnings, and vibration faults, visit our hub: Mercedes-Benz Suspension Issues – Symptoms, Causes & Fixes. There you’ll find grouped case studies, step-by-step diagnostics, symptom, cause, fix tables, and preventive tips to keep your Mercedes riding smoothly.

Common Causes of AIRMATIC Malfunctions in the W213

- – Damping valve failure (as in this case).

- – Air leaks in struts, lines, or valve blocks.

- – Faulty compressor unable to generate sufficient pressure.

- – Sensor errors from height or pressure sensors.

- – Control unit faults leading to communication errors.

Symptoms Owners Should Watch For

- – “AIRMATIC malfunction” message on the dashboard.

- – Car sitting too low, especially after being parked overnight.

- – Rough, bouncy, or unstable ride.

- – Suspension not responding when switching modes.

- – Compressor running constantly or making loud noises.

- – Vehicle leaning to one side.

FAQs

Q: Can I drive my Mercedes with an AIRMATIC malfunction?

A: Yes, but it’s not recommended. The suspension may be uneven or unresponsive, affecting safety and comfort.

Q: How much does it cost to repair an AIRMATIC malfunction?

A: Costs vary depending on the fault. Damping valve replacement can range from $700–$1,500, while compressor or air spring replacement may cost more.

Q: Do I need to replace both damping valves if one fails?

A: Not always, but it’s best practice to inspect both. Replacing in pairs may prevent uneven performance.

Q: How long does the AIRMATIC system last?

A: With proper maintenance, most components last 6–10 years. Regular inspections help catch leaks or faults early.

Q: What tools are needed to diagnose AIRMATIC problems?

A: Professional tools like Xentry Diagnostics are required for accurate fault code reading, live data analysis, and system calibration.

Conclusion

This case study of an AIRMATIC malfunction in the Mercedes-Benz E-Class W213 demonstrates how a systematic diagnostic approach can save time and prevent unnecessary part replacements.

By analyzing fault codes, checking voltages, and measuring resistance, the issue was traced to a defective right front damping valve. Replacing the faulty valve and recalibrating the system restored the E-Class to its smooth, comfortable ride quality.

For Mercedes owners, the lesson is clear: never ignore an AIRMATIC warning. With timely diagnosis and repair, you can maintain the safety, comfort, and prestige that make a Mercedes truly stand out.

Author

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last Updated: September 2025

Leave a Reply