Table of Contents

Auxiliary Battery Malfunction Mercedes

Seeing the dreaded “Auxiliary Battery Malfunction” warning on your Mercedes dashboard? You’re not alone. This message can appear suddenly and often leaves drivers confused about whether it’s a serious problem or just a minor electrical glitch.

In this article, we’ll break down what the auxiliary battery actually does, why this warning shows up, and most importantly how you can fix it quickly and safely. Whether you’re driving an A-Class, E-Class, C-Class, or GLE, these tips apply across most modern Mercedes-Benz models.

Symptoms of Auxiliary Battery Malfunction:

- Warning message on the dashboard: “Auxiliary Battery Malfunction” or “Auxiliary Battery See Owner’s Manual.”

- Electrical systems not functioning correctly, such as issues with start-stop functionality.

- Flickering dashboard lights or intermittent power in accessories.

- Occasional difficulty starting the vehicle.

Case Study : Auxiliary Battery Malfunction Mercedes A Class

1. Customer Complaint and Initial Observations

Symptom Description: The owner noticed that the vehicle’s cranking was sluggish, indicating a weak battery. After replacing the main battery under the hood, the car started, but the dashboard displayed the “Auxiliary Battery Malfunction” message. This raised several questions for the owner:

- What could be causing the malfunction?

- Is this a DIY project, or does it require professional intervention?

- Can the car be driven to the dealer, or should it be towed?

The owner was concerned about the complexity of the issue and whether it was safe to drive the car in its current condition. They were also unsure about the steps required to resolve the problem, including whether they could replace the auxiliary battery themselves.

2. Diagnosis and Initial Steps

Determining the Feasibility of a DIY Fix: To decide whether this issue was a DIY project or required a dealer’s expertise, the following steps were taken:

- Consulting the Vehicle Manual: The owner reviewed the vehicle’s manual for guidance on the auxiliary battery’s location and replacement procedure.

- Checking for Warning Lights: The dashboard displayed the “Auxiliary Battery Malfunction” warning, prompting further investigation.

- Online Research: The owner searched online forums and resources for similar issues and potential solutions.

Questions to Consider:

- Can I Drive It to the Dealer? The owner needed to determine if the car could be driven to the dealer without causing further damage or if it needed to be towed.

- Is It Safe to Attempt a DIY Fix? Considering the complexity of modern vehicles, the owner weighed the pros and cons of attempting the repair themselves.

DIY Approach to Fixing the Auxiliary Battery

If the decision was made to attempt a DIY fix, the following detailed steps were essential:

Step-by-Step Guide to Accessing and Replacing the Auxiliary Battery

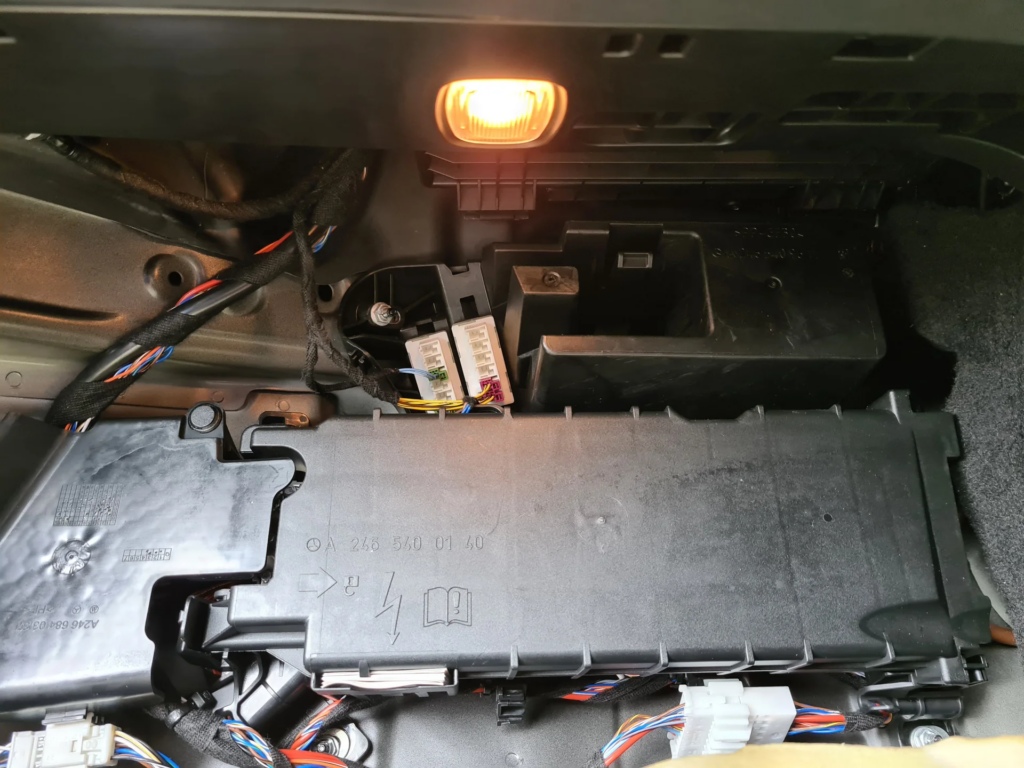

1. Locating the Auxiliary Battery:

- Position: In the A Class also CLA, B Class and GLA the auxiliary battery is typically located in the passenger footwell, behind the glove box.

- Preparation: Ensure the car is parked on a flat surface with the ignition turned off and the keys removed.

2. Removing the Auxiliary Battery Cover:

- Initial Steps: Pop the clips holding the cover in place. This can usually be done with a flat-head screwdriver or a trim removal tool.

- Hinge Issue: The hinge at the top may interfere with the glove box. Gently pull the cover upwards, and if the hinge is blocking access, carefully maneuver the cover to avoid damaging it.

3. Battery Replacement Procedure:

- Disconnecting the Old Battery:

- Use a wrench to disconnect the negative terminal first, followed by the positive terminal.

- Label the terminals if needed to ensure correct reconnection.

- Installing the New Battery:

- Position the new battery in the compartment, connecting the positive terminal first, followed by the negative terminal.

- Secure the battery with the bracket and ensure all connections are tight.

4. Reassembling the Battery Cover:

- Reattach the cover, ensuring all clips are securely fastened.

- Check for any loose parts or tools left behind.

Tools Required:

- Flat-head screwdriver or trim removal tool

- Wrench set

- Replacement battery (ensure it matches the specifications of the original)

Safety Precautions:

- Wear safety gloves and eye protection.

- Disconnect the battery to avoid any electrical shorts or shocks.

When to Seek Professional Help

Signs Indicating Professional Intervention:

- Persistent warning lights or error messages after battery replacement.

- Difficulty in removing the battery cover or accessing the battery compartment.

- Unfamiliarity with electrical components and their connections.

Professional Assistance Considerations:

- Dealer Services: A certified Mercedes-Benz dealer or a reputable service center has the tools and expertise to handle complex issues.

- Transporting the Vehicle: If the car is not driveable, consider towing it to the nearest service center to prevent further damage.

Auxiliary battery Mercedes

Role of the Auxiliary Battery:

- Functionality: The auxiliary battery supports the car’s electrical systems, including the start/stop function, interior lighting, and control units.

- Common Causes of Malfunction: Age, poor connections, or underlying electrical issues can cause the auxiliary battery to fail.

Consequences of Ignoring the Malfunction:

- Electrical Failures: Ignoring the warning can lead to failures in critical systems, including the start/stop function and comfort electronics.

- Potential Damage: Prolonged use with a malfunctioning battery can damage other electronic components.

In conclusion, addressing an auxiliary battery malfunction Mercedes A Class can be a manageable task for those with basic automotive knowledge. However, it’s essential to weigh the risks and benefits of a DIY fix versus professional help. Ensuring the auxiliary battery’s functionality is crucial for the vehicle’s overall electrical health and performance.

Auxiliary Battery Malfunction e350

Purpose of the Auxiliary Battery in the E350

The auxiliary battery in the Mercedes E350, like in other Mercedes models, is designed to support the electrical systems of the car, especially during the engine start-stop functions. It helps maintain the vehicle’s electronic stability, powering components such as the COMAND system, dashboard, and safety features when the main battery is not actively supplying power.

Symptoms Specific to the E350

- Dashboard Warning Message: A message saying “Auxiliary Battery Malfunction” will typically appear on the dashboard, indicating an issue.

- Failure of Start-Stop Functionality: The engine’s start-stop system may fail to work correctly, often defaulting to the engine staying on or turning off unexpectedly.

- Electronic Issues: Flickering or dimming of dashboard lights, issues with radio or navigation, and malfunctions in other electrical systems.

Common Causes in the E350

- Battery Age and Wear: The auxiliary battery in the E350, typically located under the hood or inside the trunk, wears out over time, losing its ability to hold charge efficiently.

- Defective Voltage Converter or Control Module: The control module that regulates the auxiliary battery’s charging process can fail, leading to insufficient charging.

- Wiring and Connections Problems: Loose, damaged, or corroded wires and terminals can interrupt the flow of power, causing the malfunction warning to appear.

Diagnostic Steps for the E350

- Scan for Fault Codes: Use an OBD-II scanner to identify any fault codes related to the auxiliary battery. Codes like B1D13 or B212D are common indicators of battery-related issues.

- Visual Inspection: Check for corrosion or physical damage to the battery and connections.

- Test Battery Voltage: Measure the auxiliary battery voltage; readings below the normal range (typically 12V or more) can confirm a failing battery.

- Check the Voltage Converter and Module: These components need to be tested to ensure they are functioning properly and charging the battery adequately.

Solutions for the E350 Auxiliary Battery Malfunction

- Replace the Auxiliary Battery: A straightforward solution is to replace the battery with a suitable model compatible with the E350.

- Repair or Replace the Voltage Converter: If the converter is faulty, it will need to be repaired or replaced to restore proper charging functionality.

- Inspect and Repair Electrical Connections: Tighten loose connections and clean any corrosion from the terminals to ensure proper power flow.

These points can help you outline the specifics of the auxiliary battery malfunction in the Mercedes E350, providing valuable insights for readers facing similar issues. Let me know if you need more details or a structured outline for your article!

What causes auxiliary battery malfunction mercedes

If your Mercedes displays the “Auxiliary Battery Malfunction” warning, it’s a sign that something in the vehicle’s electrical support system isn’t working as it should. While the main battery handles engine start-up and major functions, the auxiliary battery powers essential electronics like start/stop systems and emergency functions.

Before you rush to replace it, let’s explore the most common reasons this warning might appear.

Worn-Out Auxiliary Battery

Over time, the auxiliary battery loses its ability to hold a charge, especially after 3–5 years of service.

Low Voltage or Dead Battery

If the voltage drops below the system threshold, the ECU triggers the malfunction warning.

Bad Battery Control Module

A malfunctioning battery sensor or module can send incorrect data to the ECU, triggering a false warning.

Corroded or Loose Wiring Connections

Poor electrical contact between the battery and the vehicle’s systems may cause intermittent malfunctions.

Recent Battery Replacement Without Reset

If a new battery is installed and the system isn’t reset via diagnostic tools, the warning may remain active.

Extreme Temperatures

Cold or excessive heat can affect the auxiliary battery’s performance and lead to warning signals.

Faulty Ground or Fuse

A blown fuse or bad ground point for the battery circuit can also trigger the malfunction warning.

How to Reset Mercedes Auxiliary Battery Malfunction

Once you’ve replaced or fixed the auxiliary battery in your Mercedes, the malfunction warning may still appear on the dashboard. In most cases, the system needs to be manually reset. Here are your options:

1. Drive Cycle Reset

- Sometimes, simply driving the vehicle for 10–15 minutes allows the ECU to recheck the system and clear the warning automatically.

2. Soft Reset (Battery Disconnect Method)

- Disconnect the negative terminal of the main battery for 10–15 minutes.

- Reconnect it and start the car.

- This may reset minor warning messages, including the auxiliary battery alert.

3. Use a Diagnostic Tool (Most Effective Method)

- Plug in a Mercedes-compatible OBD-II scanner (like XENTRY).

- Go to the “Energy Management” or “Battery Control Module”.

- Clear the fault code and confirm if the auxiliary battery is functioning correctly.

- This is the most accurate and recommended reset method.

Leave a Reply