Table of Contents

Braking System Warning Light Mercedes: Real Case Study & Diagnostic Fix

When the Braking System Warning Light appears on your Mercedes dashboard, it’s more than just an icon it’s a direct signal that one of your car’s most critical safety systems has detected a fault.

This light can be triggered by low brake fluid, electrical or hydraulic malfunctions, or communication faults within the ABS/ESP network.

In this article, we’ll walk through a real-world Mercedes-Benz C-Class W205 case study, where the braking system warning light was caused by a damaged ABS wiring harness, leading to multiple fault codes and complete system disruption.

For a full overview of Mercedes brake-related systems and faults, visit: Mercedes Brake System Problems: ABS, ESP & Brake Assist Guide

Vehicle Overview

- – Model: Mercedes-Benz C-Class C300 (W205)

- – System: ABS / EPB / ESP

- – Customer Complaint: “Braking System Warning Light” illuminated on cluster

The driver reported that the red brake warning light appeared during driving, sometimes accompanied by ABS and ESP error messages. No changes in pedal feel were noticed, but the customer wanted the system checked before it escalated.

Step 1 : Initial Diagnostics

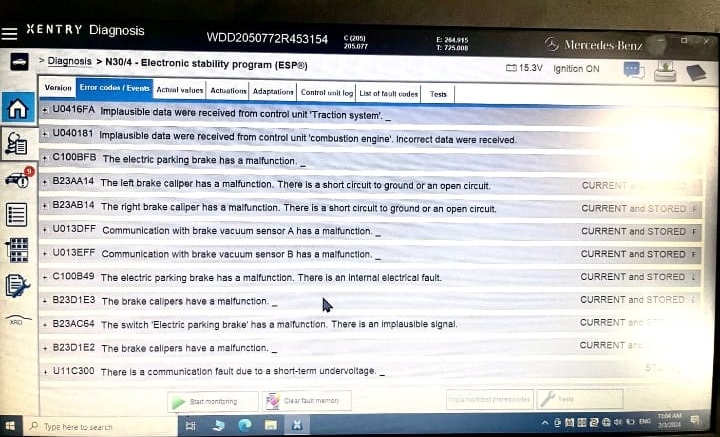

The vehicle was connected to the Mercedes XENTRY diagnostic system for a complete fault memory readout.

Stored fault codes included:

- U0416FA: Implausible data received from the Traction system control unit.

- U040181: Implausible data received from the combustion engine control unit.

- C1008F8: The electric parking brake has a malfunction.

- 13234A14: Left brake caliper malfunction; short circuit to ground or an open circuit.

- 1323A814: Right brake caliper malfunction; short circuit to ground or an open circuit.

- U013DFF: Communication malfunction with brake vacuum sensor A.

- U013EFF: Communication malfunction with brake vacuum sensor B.

- C100849: The electric parking brake has an internal electrical fault.

- B23D1E3: Malfunction in the brake calipers.

- B23AC64: Malfunction in the electric parking brake switch; implausible signal.

- 132301E2: Malfunction in the brake calipers.

- U11C300: Communication fault due to a short-term undervoltage.

Seeing these multiple network communication faults, the technician immediately suspected either:

- 1. A wiring harness integrity issue, or

- 2. Voltage instability from the main supply or module ground.

Step 2 : Physical Inspection

The first inspection focused on fluid level, fuses, and brake pad sensors all within normal limits.

Attention then turned to the electrical architecture, specifically the ABS modulator and its wiring harness, since it forms the communication bridge for both the ESP and EPB systems.

During a visual check under the vehicle, the technician noticed gnaw marks and missing insulation on the lower harness leading to the ABS control unit.

Closer inspection revealed the truth:

- – The harness had been chewed through by a rodent, severing CAN lines and power feeds to the module.

- – This confirmed the cause of the random implausible and communication faults across the braking network.

Step 3 : Repair Process

1. Component Access

The technician removed the ABS modulator carefully to expose the damaged harness section.

All connector pins were cleaned and checked for oxidation or moisture intrusion.

2. Harness Repair

The damaged wires were trimmed, soldered, and heat-shrunk with OEM-grade insulation.

Each repaired wire was color-matched according to the wiring diagram to ensure correct pin alignment and CAN polarity.

3. Protective Sealing

A loom sheath and rodent-resistant insulation wrap were installed to prevent future damage.

4. System Reassembly

The repaired harness was re-routed, secured, and connected to the ABS modulator.

All connectors were locked, and ground points were re-torqued.

Step 4 : Verification & Final Diagnostics

After reassembly, the technician:

- – Cleared all previous fault codes.

- – Monitored live CAN data to verify stable communication.

- – Performed a short test of the ABS, ESP, and EPB modules.

- – Conducted a road test with active data logging.

Result:

No fault codes returned, the Braking System Warning Light disappeared, and full braking performance (including the electric parking brake) was restored.

Root Cause Summary

| Fault | Source | Repair Action | Result |

|---|---|---|---|

| Multiple communication DTCs (U-series) | Damaged CAN wiring under ABS modulator | Spliced, soldered, sealed harness | Stable network |

| EPB and caliper faults | Lost CAN continuity | Restored wiring integrity | Normal EPB response |

| Short-term undervoltage | Result of intermittent CAN | Verified alternator/battery OK | No recurrence |

Technician’s Insight

“When you see over ten fault codes from different modules at once, it’s rarely ten bad components, it’s one broken link.

In this Mercedes, the chewed harness completely interrupted CAN communication between the brake system modules, creating a cascade of implausible signals. Once that connection was restored, every warning cleared instantly.”

Preventive Advice

- – Inspect wiring harnesses if your car is parked outdoors for long periods.

- – Use rodent deterrent spray or ultrasonic repellents near engine bays.

- – Maintain a healthy 12.6 V+ battery voltage : undervoltage can mimic network faults.

- – Schedule periodic full system scans (XENTRY or iCarsoft MBII) every 6–12 months.

FAQ: Mercedes Braking System Warning Light

Q1: Can I drive when the braking system light is on?

Only if the brake pedal feels normal and the vehicle stops evenly. If the pedal is soft or braking feels abnormal, stop immediately and call for assistance.

Q2: What’s the most common cause of this light?

Low brake fluid or pad wear sensors but multiple system lights usually indicate a CAN wiring or voltage issue.

Q3: Why did my warning disappear after a restart?

Temporary undervoltage or communication glitch; if it returns, perform a diagnostic scan.

Q4: Does ABS or ESP stop working with this warning?

In most cases, yes. Safety assist functions may be deactivated until the fault is repaired.

Q5: How can I prevent wiring damage?

Keep the engine bay clean, avoid food remnants near parking areas, and inspect harnesses after rodent exposure.

Conclusion

This Mercedes-Benz C-Class W205 case study highlights how a simple harness fault can cause complex brake system errors.

By following a logical, step-by-step diagnostic method from fault memory to physical inspection the technician identified and resolved the real cause without unnecessary parts replacement.

After the repair, the Braking System Warning Light was cleared, the braking network restored, and the vehicle returned safely to the customer.

For more Mercedes braking-related troubleshooting, see: Mercedes Brake System Problems: ABS, ESP & Brake Assist Guide

Author Bio

Mercedes Expert is an automotive technical trainer and Mercedes-Benz diagnostics expert with extensive hands-on experience in XENTRY, DTS Monaco, and advanced system troubleshooting. He specializes in transforming real workshop case studies into structured learning content to help technicians, car owners, and enthusiasts understand complex vehicle systems.

Last update: October 2025

Leave a Reply