Table of Contents

Diesel Particulate Filter Problems in Mercedes-Benz E Class 212 with OM651 Engine

Diesel particulate filter problems are a common concern for owners of modern diesel vehicles, including the Mercedes-Benz E Class 212 equipped with the OM651 engine. The Diesel Particulate Filter (DPF) is an essential component in reducing vehicle emissions, but when issues arise, they can significantly affect the car’s performance.

This article explores a real-life case study to understand the symptoms, diagnosis, and resolution of DPF-related problems, along with practical information on cleaning, location, and differential pressure sensors.

Case Study: Diagnosing Diesel Particulate Filter Problems

Vehicle: Mercedes-Benz E Class 212 (OM651 Engine)

Customer Complaint: The customer brought the vehicle to the workshop due to diesel particulate filter light.

Diagnosis and Testing

1. Quick Test:

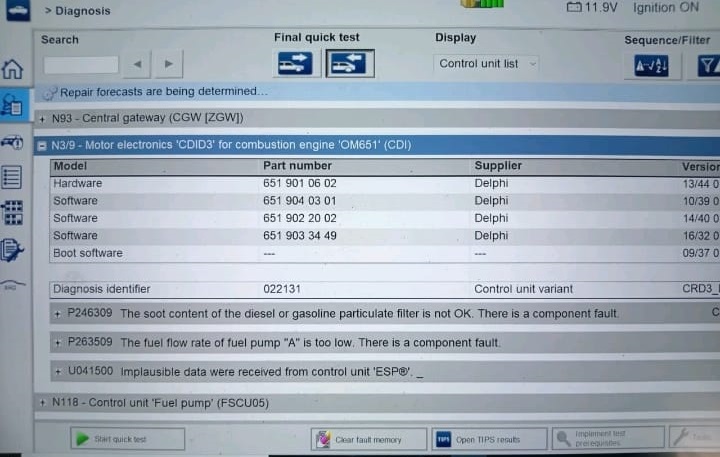

- Using the Xentry diagnostic tool, a quick test was conducted to analyze fault codes stored in the engine control unit.

2. Fault Code Analysis:

- The results indicated a blocked diesel particulate filter as the root cause of the engine warning light.

Solution

DPF Regeneration:

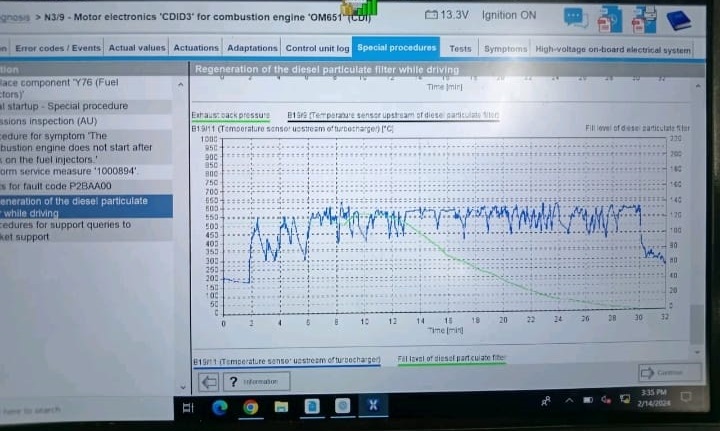

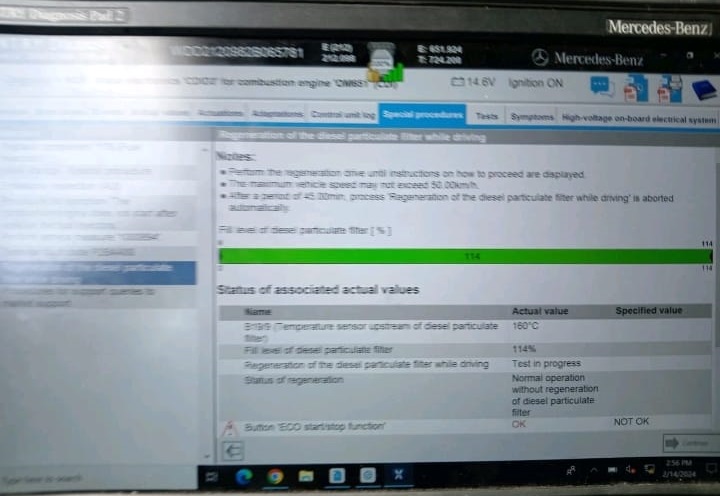

- A forced regeneration of the DPF was performed using the Xentry tool.

- The process successfully burned off the accumulated soot and ash, restoring the filter’s efficiency.

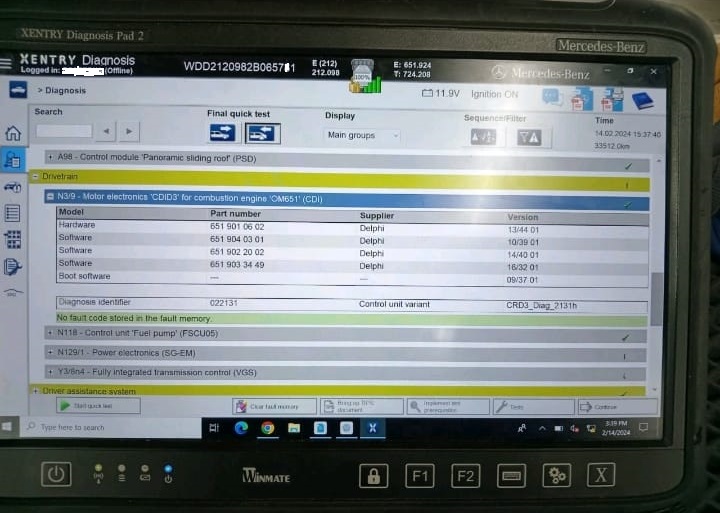

Final Checks:

- Fault codes were cleared, and the vehicle’s performance was re-evaluated. The engine light remained off, confirming the issue was resolved.

Understanding Diesel Particulate Filter Problems

What is a Diesel Particulate Filter?

The DPF is a critical component in diesel vehicles, designed to trap and reduce particulate matter emitted from the exhaust. Over time, soot accumulates in the DPF, and if not burned off through regeneration, it can lead to blockages and reduced engine performance.

Symptoms of a Blocked DPF

– Illuminated engine warning light

– Reduced power or performance

– Increased fuel consumption

– Noticeable exhaust odor

Diesel Particulate Filter Regeneration

DPF regeneration is a process that removes the accumulated soot and ash inside the filter to restore its functionality. There are three main types of DPF regeneration:

1. Passive Regeneration:

– Occurs automatically during normal vehicle operation when the exhaust temperature is sufficiently high (e.g., during sustained highway driving).

– This process burns off soot particles gradually without the driver’s intervention.

2. Active Regeneration:

– Initiated by the engine control unit (ECU) when the DPF reaches a specific level of soot load.

– Extra fuel is injected to increase exhaust temperature and burn off soot particles.

– Drivers may notice changes like increased fuel consumption or a hot smell during this process.

3. Forced Regeneration:

– Performed in a workshop using diagnostic tools like Xentry.

– This method is required when passive and active regeneration fail to clear the soot.

– The vehicle is kept at specific conditions (e.g., higher RPM) to heat the DPF and burn off soot and ash effectively.

Tips for Successful Regeneration

– Regularly drive at higher speeds (e.g., highway driving) to facilitate passive regeneration.

– Avoid frequent short trips that prevent the exhaust from reaching the necessary temperature.

– Follow the vehicle’s maintenance schedule to ensure the DPF and related components function correctly.

How to Clean Diesel Particulate Filter

Cleaning a diesel particulate filter can involve several methods, depending on the severity of the blockage:

1. Passive Regeneration:

- Occurs automatically when the vehicle is driven at sustained high speeds, allowing the exhaust temperature to rise and burn off accumulated soot.

2. Active Regeneration:

- The engine management system initiates a fuel injection process to increase exhaust temperatures and clean the filter.

3. Forced Regeneration:

- A workshop procedure performed using diagnostic tools like Xentry to raise the temperature in the DPF and clear blockages.

4. Chemical Cleaning:

- Specialized cleaning agents are introduced to break down and remove soot and ash. This method is suitable for heavily blocked filters and often requires removal of the DPF.

5. Replacement:

- If cleaning is ineffective, replacing the DPF may be the only solution.

Diesel Particulate Filter Location

In the Mercedes-Benz E Class 212 with the OM651 engine, the DPF is typically located:

– Beneath the vehicle, integrated into the exhaust system.

– Close to the engine for optimal temperature retention, ensuring efficient particulate matter combustion.

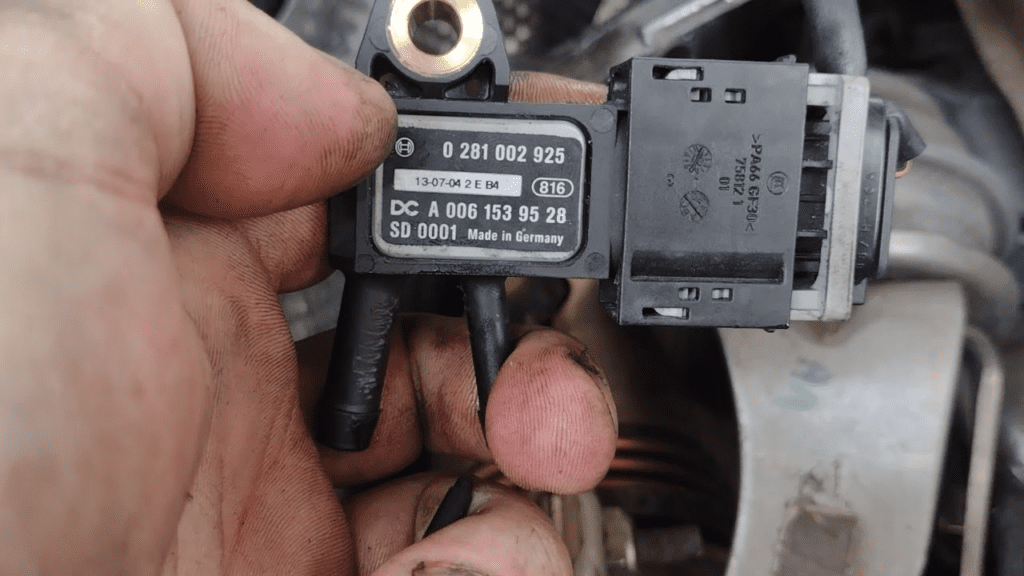

Diesel Particulate Filter Differential Pressure Sensor

The differential pressure sensor plays a vital role in monitoring the condition of the DPF:

– Function: Measures pressure differences across the filter to determine soot accumulation levels.

– Location: Positioned near the DPF, often mounted on the exhaust pipe with two hoses connecting it to the filter.

– Symptoms of Fault:

1: Incorrect readings can lead to false DPF warnings.

2: Engine light activation despite a clean filter.

– Testing and Replacement:

1: Use diagnostic tools to verify sensor accuracy.

2: Replace the sensor if it provides faulty readings.

Preventing Diesel Particulate Filter Problems

1. Regular Maintenance:

- Schedule periodic checks to monitor DPF performance and address issues early.

2. Driving Habits:

- Avoid excessive idling or frequent short trips.

- Include highway driving to allow passive regeneration.

3. Quality Fuel:

- Use high-quality diesel to reduce soot production.

Conclusion

Diesel particulate filter problems can be a significant inconvenience, but understanding the symptoms and solutions can help maintain optimal vehicle performance. For Mercedes-Benz E Class 212 owners, regular maintenance and informed driving habits are key to preventing costly repairs.

By utilizing diagnostic tools like Xentry and following proper cleaning methods, DPF issues can be effectively managed, ensuring a smoother and more reliable driving experience.

Leave a Reply