Table of Contents

Mercedes EQB Issue: Suspension Warning on Cluster : A Detailed Case Study

The Mercedes-Benz EQB is one of the brand’s standout electric SUVs, combining luxury, practicality, and advanced driving technology. But like all modern vehicles, even the EQB can experience issues that disrupt its smooth performance. One of the more alarming problems for owners is a suspension warning on the instrument cluster.

In this article, we’ll explore a real-world Mercedes EQB case study where a suspension fault warning appeared on the dashboard. We’ll walk through the diagnostic steps, root cause, repair process, and resolution providing a blueprint for how similar issues can be handled effectively.

Customer Complaint

The owner of a Mercedes EQB reported a suspension warning light illuminated on the cluster. This warning pointed to a fault in the Adaptive Damping System (ADS) a vital part of the suspension system that ensures stability and comfort.

Because the ADS manages ride quality by continuously adjusting damping at each wheel, any fault in the system can compromise both safety and driving experience.

Diagnostic Process

Step 1: Performing a Quick Test

The repair process began with a quick test using the Mercedes-Benz Xentry diagnostic tool. This provided initial fault codes and narrowed down the problem to the suspension system.

Step 2: Checking Fault Codes

The diagnostic scan revealed non-responsiveness from the ADS control unit. This pointed to either:

- – A communication error between modules, or

- – A power supply failure affecting the ADS control unit.

Step 3: Investigating the ADS Control Unit

Since the ADS control unit plays a central role in monitoring suspension data, its non-response was treated as the root cause of the warning. Possible culprits included damaged wiring, faulty connectors, or electrical interruptions.

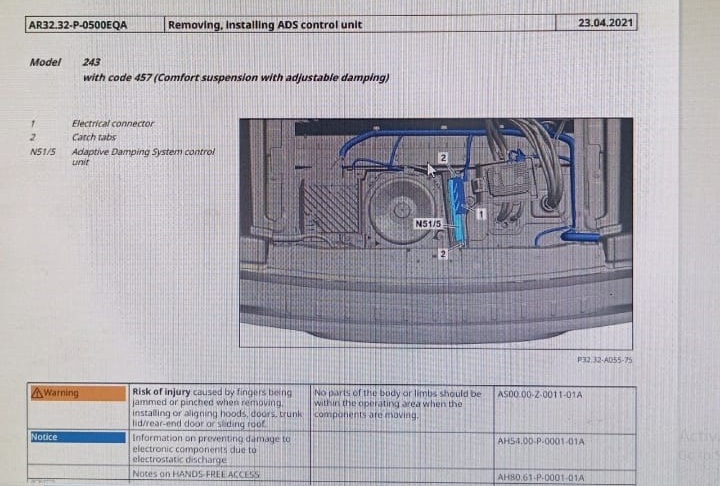

Step 4: Locating the ADS Control Unit

Using the Mercedes Workshop Information System (WIS), the ADS control unit location was identified. It is positioned to directly interface with the suspension hardware, making it crucial for vehicle stability.

Step 5: Visual Inspection of the Control Unit and Wiring

Upon physically inspecting the ADS control unit and wiring harness, technicians discovered the true cause:

- – The power supply wiring harness had been damaged by rodents.

- – The insulation had been chewed, exposing wires and disrupting power delivery.

Rodent damage is more common than many owners realize, especially in electric vehicles where soy-based insulation attracts animals.

Step 6: Repairing the Wiring Harness

The damaged wiring harness was carefully repaired and re-insulated. Steps included:

- 1. Splicing and reconnecting severed wires.

- 2. Applying protective insulation to prevent future exposure.

- 3. Adding rodent-resistant covers to safeguard against repeat incidents.

Step 7: Re-Testing and Confirming Repair

After the harness repair, a second quick test was performed with Xentry:

- – The ADS control unit responded normally.

- – The suspension warning was cleared from the dashboard.

- – A test drive confirmed that the EQB’s suspension system was fully functional again.

Symptom –> Cause –> Fix Table

| Symptom | Likely Cause | Repair Solution |

|---|---|---|

| Suspension warning on cluster | Non-responsive ADS control unit | Inspect and restore communication/power supply |

| No ADS module response in diagnostics | Damaged wiring harness or blown fuse | Repair wiring harness; replace fuse if necessary |

| Intermittent suspension faults | Loose or corroded connectors | Clean, secure, or replace connectors |

| Vehicle feels unstable or bouncy | Faulty ADS sensors or damaged wiring | Replace defective sensors, recalibrate system |

| Recurring suspension warnings | Rodent or environmental damage | Protect harness with reinforced insulation |

Related Diagnostic Resource

If your Mercedes is showing electrical or suspension-related warnings, explore our complete troubleshooting hubs:

Mercedes Electrical Problems: Fix SAM, ECU & CAN Bus Faults; learn how to diagnose power supply loss, short circuits, and CAN communication errors affecting your vehicle’s control modules and wiring systems.

Mercedes-Benz Suspension Issues: Symptoms, Causes & Fixes; discover how to identify and repair AIRMATIC, ADS, and level-sensor faults, including electrical causes and calibration tips.

Together, these resources provide a complete diagnostic roadmap from module voltage and communication faults to suspension performance and ride-height regulation issues.

Why This Issue Occurred

The suspension warning in this EQB was not caused by a failed module or sensor but by external damage to the wiring harness. This highlights how modern vehicles are vulnerable not only to electronic failures but also to environmental factors like rodents, moisture, and corrosion.

Preventive Tips for EQB Owners

- 1. Inspect Regularly: Have wiring checked during scheduled service visits.

- 2. Rodent Prevention: Park in rodent-free areas when possible; consider deterrent sprays or covers.

- 3. Respond Quickly: Never ignore suspension warnings; early diagnosis prevents costly repairs.

- 4. Use OEM Parts: Always repair with genuine Mercedes components for compatibility and reliability.

- 5. Perform Test Drives: After any suspension repair, confirm performance with a road test.

Learn more about the Mercedes-Benz EQB Issue in the next link: Coolant Leak in EV Cars: How to Easily Solve This Issue

FAQs: Mercedes EQB Issue

Q: Is it safe to drive with a suspension warning on the Mercedes EQB?

A: It is not recommended. A faulty suspension system can reduce stability, handling, and comfort especially at higher speeds or on uneven roads.

Q: Can rodents really cause suspension faults?

A: Yes. Rodents frequently chew wiring insulation, leading to electrical faults. In this case, it caused the ADS control unit to lose power.

Q: How much does it cost to repair this issue?

A: Costs vary:

- – Minor wiring repair: $200–$400

- – Harness replacement: $800–$1,200

- – If ADS module replacement is needed: $1,500–$2,000+

Q: Will the warning disappear after a reset?

A: Not if the underlying issue remains. The warning will only clear once the fault (damaged wiring, failed component, etc.) is repaired.

Q: How do technicians locate the ADS control unit?

A: They use the Mercedes Workshop Information System (WIS) to find the exact location for inspection and repair.

Conclusion

The Mercedes EQB suspension warning issue demonstrates how modern vehicles depend heavily on electronic control units and wiring integrity.

In this case study, the fault was traced to rodent damage in the ADS control unit wiring harness. By repairing the damaged wiring, recalibrating the system, and retesting with Xentry, the issue was fully resolved restoring safety and comfort for the customer.

For EQB owners, the lesson is simple: don’t ignore dashboard warnings. Seek immediate diagnostics, as problems may be electrical, environmental, or mechanical. With proper maintenance and professional repair, your Mercedes EQB will continue delivering the refined ride quality that defines the brand.

Author

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last Updated: November 2025

Leave a Reply