Table of Contents

Case Study: Transmission Shifting Problems in Mercedes-Benz

When a Mercedes suddenly shifts harshly, hesitates, or drops into limp mode, DTC P2716 is a frequent culprit. On the 722.9 (7G-Tronic) transmission used in models such as the E300 W212, this code flags an internal electrical test failure of component Y3/8y4 — the K3 clutch control solenoid (Pressure Control Solenoid “D”).

This case study walks through real-world diagnostics and repair: what we tested, what we replaced, and how we verified a lasting fix written to be clear for owners and useful for technicians.

Quick Facts

| Item | Detail |

|---|---|

| Vehicle | Mercedes-Benz E300 W212 |

| Transmission | 722.9 (7G-Tronic) |

| Primary Code | P2716 – K3 clutch control solenoid (Y3/8y4) internal electrical test failed |

| Related Codes Seen | P2759 (TCC pressure control), plus electrical faults on PRV 1, 2, 3, 5, 6, 7 |

| Typical Symptoms | Sluggish/harsh shifts, hesitation, limp mode, warning in cluster |

| Severity | High – continued driving may damage the gearbox |

| Core Fix in This Case | Valve body clean/check + VGS (TCU) replacement & programming |

Symptoms the Owner Reported

- – Noticeable hesitation on take-off and sluggish upshifts.

- – Occasional harsh engagement and reduced performance (limp strategy).

- – Transmission warning message after heavy traffic or heat soak.

What P2716 Really Means

The 7G-Tronic runs live electrical self-tests on its pressure control solenoids. If the measured current/response from Solenoid “D” (Y3/8y4) doesn’t match the expected profile, the TCU sets P2716. The K3 clutch is involved in specific gear ranges; if its pressure can’t be controlled, shift quality degrades and the TCU may force limp mode.

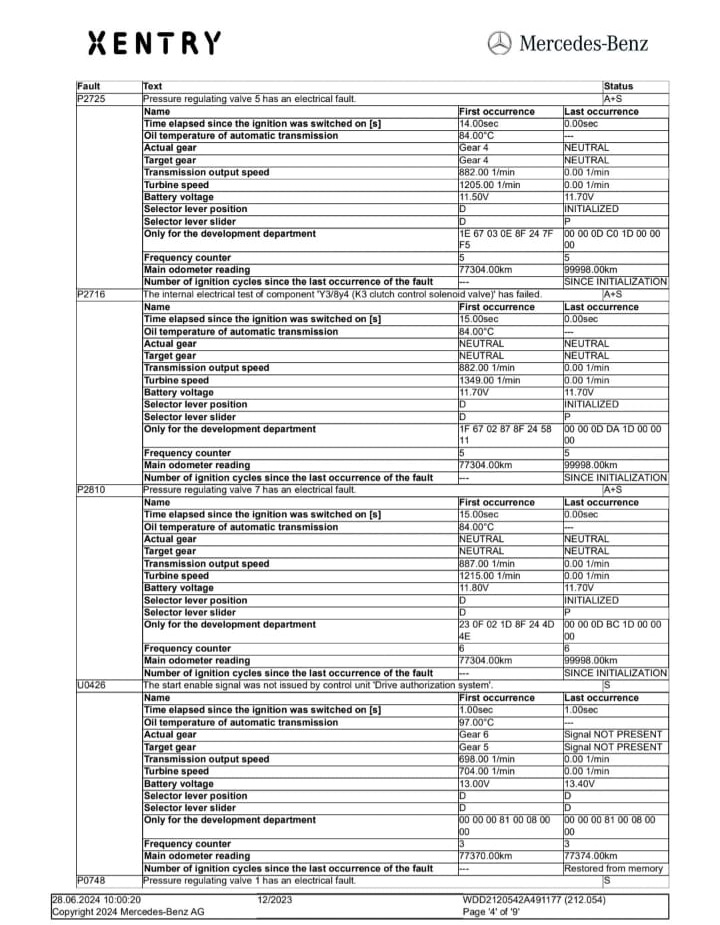

DTCs Observed (Scan Report)

| Code | Module | Description | Practical Meaning |

|---|---|---|---|

| P2716 | TCU (VGS) | Internal electrical test for Y3/8y4 (K3 solenoid) failed | Solenoid D circuit/driver out of spec |

| P2759 | TCU (VGS) | TCC pressure regulating valve – electrical fault | Torque converter lock-up pressure control issue |

| PRV 1/2/3/5/6/7 electrical faults | TCU (VGS) | Multiple pressure control valves flagged | Points to valve body contamination, wiring, or TCU driver issues |

Step-by-Step Diagnostic Workflow

- 1. Global Short Test (XENTRY)

- – Pull TCU, engine, ESP, and powertrain codes; save freeze frames.

- – Confirm P2716 as current (not stored/intermittent).

- 2. Basic Electrical Checks

- – Battery/charging system health (low voltage causes false fails).

- – Inspect transmission connectors for fluid wicking, corrosion, pin tension.

- 3. Live Data & Actuations

- – Monitor solenoid currents, clutch pressures, and input/turbine speed during a gentle road test.

- – Use guided tests to actuate individual solenoids and observe current profiles.

- 4. Resistance/Continuity (Engine OFF, Connector Unplugged)

- – Measure coil resistance of pressure control solenoids at ~20 °C.

Typical range: ~5–7 Ω (always confirm with WIS for the exact spec). - – Check harness continuity from VGS to the valve body.

- – Measure coil resistance of pressure control solenoids at ~20 °C.

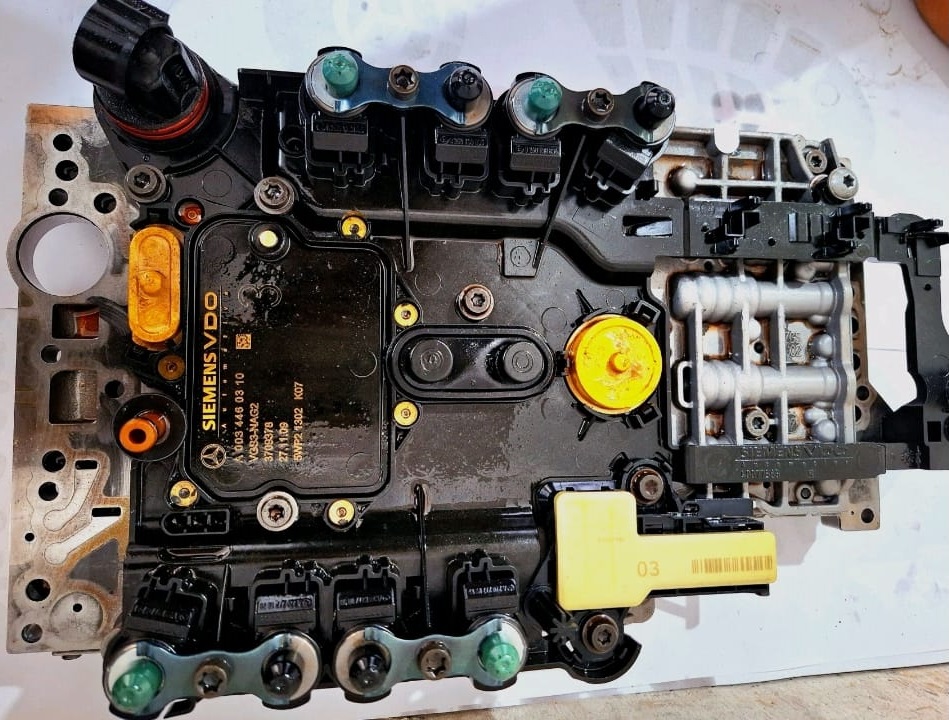

- 5. Valve Body (Mechatronics) Inspection

- – Drop the pan, remove the valve body.

- – Clean solenoids and passages with fresh ATF (per WIS), check for debris.

- – Re-check resistance values and mechanical movement (“click”) feedback.

- 6. Re-evaluate

- – If multiple solenoids still fail electrically, suspect VGS internal driver fault.

- – If only one solenoid fails and resistance is off-spec, replace that solenoid.

- 7. Programming & Adaptation

- – If VGS is replaced, program/codify and restore data (SCN coding).

- – Perform transmission adaptations once ATF temp, voltage, and preconditions are met.

Symptom → Cause → Fix (Cheat Sheet)

| Symptom | Likely Cause(s) | Fix / Verification |

|---|---|---|

| Harsh or delayed shifts, P2716 current | Y3/8y4 coil out of spec; wiring fault; VGS driver fault | Measure coil Ω; inspect harness; if multiple electrical faults persist, replace VGS |

| Multiple PRV “electrical” codes | Contaminated valve body; low voltage; VGS driver damage | Clean valve body; verify power/grounds; consider VGS |

| Limp mode after warmup | ATF contamination/overheating; adaptation aborted | Service ATF/filter; complete adaptations at correct ATF temp |

| TCC shudder + P2759 | TCC pressure regulator fault or fluid degradation | Valve body service; fluid/filter; retest |

Where is Solenoid “D” (K3) Located?

All 722.9 pressure control solenoids, including “D” (Y3/8y4), are mounted on the valve body beneath the transmission pan.

Access sequence:

- 1) Remove under-shields → 2) Drain ATF → 3) Remove pan & filter → 4) Lower valve body to expose/replace solenoids.

Always use WIS for diagrams, torque specs, and safety notes.

What We Did in This Case (Workshop Timeline)

1. Scan & Verification: P2716 current + several PRV electrical faults.

2. Valve Body Service: Removed, cleaned, and bench-checked all solenoids; resistances within typical range after cleaning, but P2716 reappeared.

3. Decision Point: Multiple persistent “electrical” flags suggested VGS internal driver failure rather than individual solenoids.

4. VGS Replacement: Installed a new VGS (TCU), performed coding + data restore.

5. Adaptations: Ran the full 7G-Tronic adaptation routine with correct ATF temperature and system voltage.

6. Road Test & QA: Smooth shifts restored; no codes on final XENTRY scan.

Related Diagnostic Resource

If your Mercedes is showing electrical or transmission-related warnings, explore our complete diagnostic hubs:

Mercedes Electrical Problems: Fix SAM, ECU & CAN Bus Faults; learn how to diagnose power supply issues, short circuits, and communication errors affecting your vehicle’s control modules and wiring systems.

Mercedes Transmission Issues: Causes and Fixes; a detailed troubleshooting guide covering shifting delays, limp mode, solenoid faults, and TCU communication problems across multiple Mercedes models.

Together, these hubs provide a complete diagnostic pathway from electrical and CAN faults affecting control units to transmission performance and shifting behavior issues.

Tools & Preconditions You Should Not Skip

| Category | Requirement |

|---|---|

| Diagnostic | XENTRY (or equivalent OE-level), ability to run actuations & adaptations |

| Electrical | Stable 12.5–14.5 V power during programming/adaptation |

| Fluids | ATF that meets MB spec for 722.9, new pan gasket & filter |

| Data | Access to WIS/ASRA for procedures, torque, and safety steps |

| Preconditions | ATF at spec temperature, no active DTCs in powertrain that block adaptation |

Cost & Time (Indicative)

| Operation | Time | Notes |

|---|---|---|

| Valve body remove/clean/refit | 3–5 h | Add ATF, filter, pan service |

| VGS replace + coding | 1–2 h | SCN coding/data restore required |

| Full adaptations + road test | 0.5–1 h | Must meet temp/voltage preconditions |

Early diagnosis can avoid repeat labor and clutch damage.

Prevention & Best Practices

- – Service ATF & filter at sensible intervals; overheated/contaminated fluid accelerates mechatronic issues.

- – Keep battery and charging system healthy low voltage makes electrical tests fail.

- – Don’t “shotgun” parts: verify coil resistance, wiring, and VGS before replacing components.

- – Run adaptations only when no related DTCs are present and ATF temp is in range.

FAQs

1) Can I clear P2716 and keep driving?

You might temporarily regain normal shifts, but the code typically returns. Driving with a pressure control fault risks clutch damage diagnose promptly.

2) Does P2716 always mean a bad solenoid?

No. It can be the solenoid, its harness/connector, contamination in the valve body, or a VGS driver failure. Follow the workflow above to isolate.

3) Will a fluid change fix P2716?

If contamination affects solenoid movement, fluid/filter service and valve-body cleaning may help but electrical faults still need electrical fixes.

4) Do I need to reprogram after VGS replacement?

Yes. The VGS must be coded (SCN) and adaptations must be completed under the correct conditions.

5) Typical coil resistance for 722.9 pressure control solenoids?

Commonly ~5–7 Ω at ~20 °C (confirm exact spec in WIS). Large deviations indicate a coil issue.

6) Where exactly is Pressure Control Solenoid “D”?

On the valve body under the transmission pan. Remove pan & filter to access; identify by WIS diagram for your transmission variant.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: November 2025

Leave a Reply