Table of Contents

AIRMATIC Compressor Failure in Mercedes-Benz E350 W212: A Full Diagnostic Case Study

The Mercedes-Benz E350 W212 combines executive luxury with advanced technology. A hallmark feature of this model is its AIRMATIC suspension system, designed to deliver a smooth, adjustable ride. However, like any complex system, AIRMATIC can develop faults. One of the most common and disruptive issues is AIRMATIC compressor failure.

This case study documents a real-world repair on a Mercedes-Benz E350 W212 brought into the workshop with a sagging front end, back end and a warning message on the cluster: “AIRMATIC Malfunction.” We’ll break down the diagnostic process, repair steps, and the symptoms drivers should watch for when the compressor begins to fail.

Vehicle & Complaint

- Model: Mercedes-Benz E350 (W212)

- Customer Complaint: “AIRMATIC malfunction” displayed on the cluster and vehicle sitting too low.

At arrival, the front and rear of the vehicle was noticeably lower, confirming that the suspension was not maintaining proper ride height.

Step-by-Step Diagnostic & Repair Process

Step 1: Initial Inspection

- – Visual check revealed the front suspension had collapsed.

- – AIRMATIC warning confirmed the system was unable to pressurize and maintain ride height.

Conclusion: Strong suspicion of compressor or air system failure.

Step 2: Diagnostic Scan with Xentry

- – Connected Xentry Diagnostics via OBD-II port.

- – Retrieved multiple fault codes related to level control system.

- – Live data confirmed the system was not building sufficient air pressure.

Step 3: Compressor Function Test

- – Attempted to activate compressor via Xentry.

- – No response → compressor did not engage.

- – Electrical supply tested positive (voltage present).

Conclusion: Compressor received power but failed to operate → internal compressor fault.

Step 4: Leak Check

- – Manual leak test performed across air springs, hoses, and valve block.

- – No significant leaks detected.

Conclusion: The lack of leaks pointed more strongly to a compressor failure rather than air loss.

Step 5: Final Diagnosis

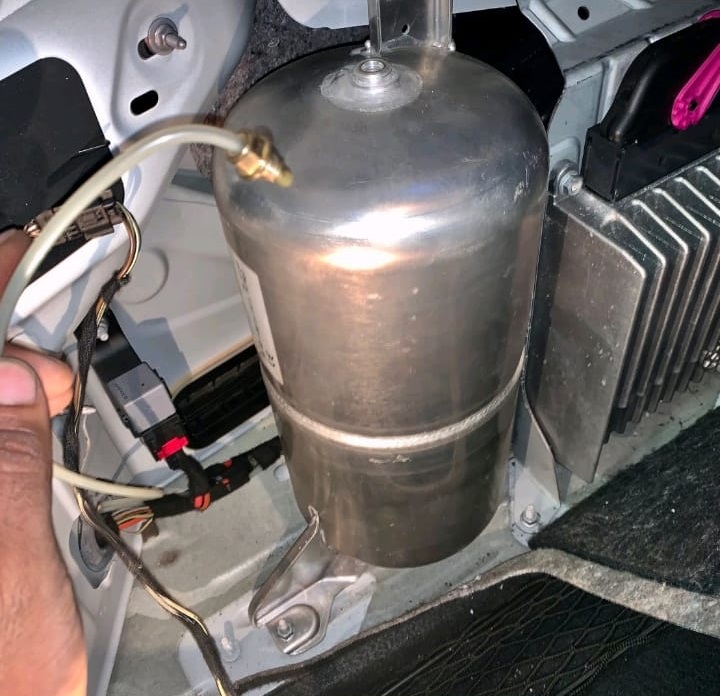

The compressor was defective unable to generate or maintain system pressure. The solution: replace the compressor unit.

Step 6: Replacement Process

- 1. Preparation

- – Vehicle safely lifted.

- – Battery disconnected for safety.

- – Suspension depressurized.

- 2. Removal

- – Old compressor and relay removed.

- – Electrical connectors and air lines disconnected.

- 3. Installation

- – New OEM Mercedes compressor installed.

- – Relay replaced to ensure compatibility.

- – Air lines reconnected and sealed.

- 4. Calibration

- – Using Xentry, recalibrated ride height and system parameters.

- – Cleared all stored fault codes.

Step 7: Quality Check

- – Restarted vehicle: AIRMATIC system successfully raised car to normal height.

- – No warning lights present.

- – Conducted test drive → suspension adjusted correctly with no sagging or abnormal noises.

Outcome: AIRMATIC compressor failure resolved.

Symptom – Cause – Fix Table

| Symptom | Likely Cause | Repair Solution |

|---|---|---|

| Car sitting too low (front/rear) | Failed compressor | Replace compressor unit |

| “AIRMATIC malfunction” warning | Compressor failure or wiring issue | Diagnose with Xentry, replace compressor or relay |

| Vehicle fails to raise after start | Compressor unable to build pressure | Install new compressor, recalibrate system |

| Noisy compressor / grinding sounds | Worn internal compressor parts | Replace compressor with OEM unit |

| Compressor runs continuously | System leak or compressor inefficiency | Check leaks, replace compressor if defective |

Symptoms of a Bad AIRMATIC Compressor

Drivers often ask: “How do I know if my AIRMATIC compressor is failing?” Here are the most common signs:

- 1. Sagging or uneven ride height : vehicle sits too low, especially after parking overnight.

- 2. Warning message: “AIRMATIC malfunction” on the dashboard cluster.

- 3. Failure to raise : car remains low after ignition.

- 4. Unusual compressor noise : loud rattling, grinding, or humming.

- 5. Extended run time : compressor runs constantly but never restores ride height.

- 6. Leaning to one side : indicates compressor cannot distribute enough pressure.

- 7. Harsher ride : lack of suspension inflation makes ride stiff and bumpy.

- 8. Frequent compressor activation : system overworks due to weak output.

- 9. Electrical strain : failing compressor may draw excess current.

- 10. Stored fault codes : diagnostic scan shows level control or compressor errors.

Explore More Mercedes Suspension Issues

For a deeper dive into suspension problems such as uneven ride height, AIRMATIC malfunctions, “Stop Vehicle Too Low” warnings, and vibration faults, visit our hub: Mercedes-Benz Suspension Issues – Symptoms, Causes & Fixes. There you’ll find grouped case studies, step-by-step diagnostics, symptom, cause, fix tables, and preventive tips to keep your Mercedes riding smoothly.

Why Do Compressors Fail?

- – Wear & tear: Normal aging leads to loss of efficiency.

- – Overuse: Continuous running caused by leaks burns out the motor.

- – Blocked air filters: Reduce airflow, forcing compressor to overwork.

- – Electrical relay faults: Prevent compressor from shutting down properly.

- – Moisture damage: Water ingress can corrode internal components.

FAQ: AIRMATIC Compressor Failure in Mercedes

Q: How long does a Mercedes AIRMATIC compressor last?

A: Typically 6–10 years or around 80,000–100,000 miles, depending on driving conditions.

Q: Can I drive with a bad AIRMATIC compressor?

A: Short distances may be possible, but unsafe. The vehicle may sit too low, reduce handling stability, and damage tires or drivetrain.

Q: Should I replace the compressor or just repair it?

A: Replacement is usually best. Rebuilding is possible but less reliable for long-term performance.

Q: How much does it cost to replace an AIRMATIC compressor?

A: Parts and labor typically range from $1,000–$1,800 at a dealership. Independent workshops may be more affordable.

Q: Do I need to recalibrate the suspension after replacement?

A: Yes. Calibration ensures proper ride height and system balance. Skipping this step may trigger warning lights again.

Conclusion

This case study of the Mercedes-Benz E350 W212 AIRMATIC compressor failure highlights the importance of systematic diagnostics and OEM-level tools. The combination of Xentry diagnostics, electrical checks, and manual leak tests confirmed that the compressor not leaks was the root cause of the malfunction.

By replacing the defective compressor, recalibrating the suspension, and performing thorough testing, the E-Class was restored to its proper ride height and comfort.

Author

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last Updated: September 2025

Leave a Reply