Table of Contents

Case Study: Car Won’t Accelerate in a Mercedes-Benz G Class W463 Equipped with M273 Engine

One of the most frustrating issues a driver can experience is when a car won’t accelerate as expected. This article will explore a case study of a Mercedes-Benz G Class W463, equipped with the M273 Engine, where the customer reported an issue: the car won’t accelerate. We’ll walk through the diagnostic process, the fault codes encountered, and how the problem was ultimately resolved.

Customer Complaint: Car Won’t Accelerate

A customer arrived at the workshop with their Mercedes-Benz G Class W463, stating that the car won’t accelerate properly. The vehicle exhibited sluggish performance, and the customer reported difficulty in getting the car to respond to throttle input.

Initial Diagnosis

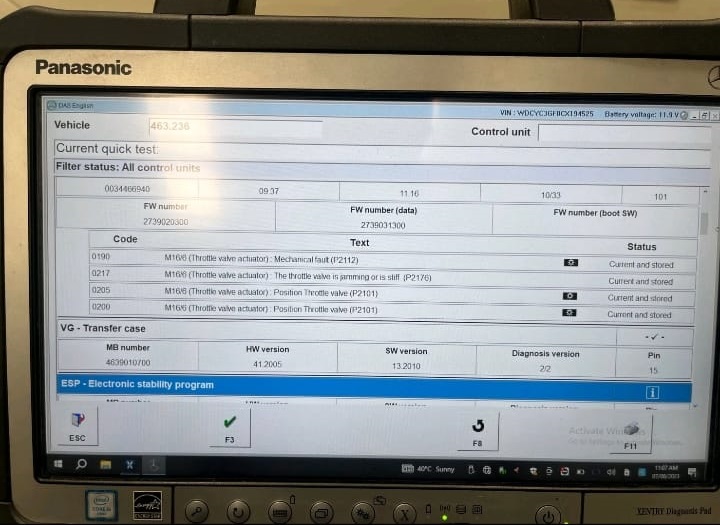

To identify the root cause of why the car won’t accelerate, we started by connecting the vehicle to the Xentry diagnostic system. This tool provides valuable insights into the car’s electronic control units (ECUs) and various system faults.

Upon running the diagnostic test, several fault codes related to the throttle valve actuator were revealed:

- 0190 M16/6 (Throttle Valve Actuator): Mechanical fault (P2112).

- 0217 M16/6 (Throttle Valve Actuator): Throttle valve is jamming or is stuck.(P2176)

- 0205 M16/6 (Throttle Valve Actuator): Throttle valve position error.

- 0200 M16/6 (Throttle Valve Actuator): Throttle valve position fault (P2101).

These codes indicated that the throttle valve actuator was malfunctioning, leading to the vehicle’s inability to accelerate properly.

Diagnostic Approach

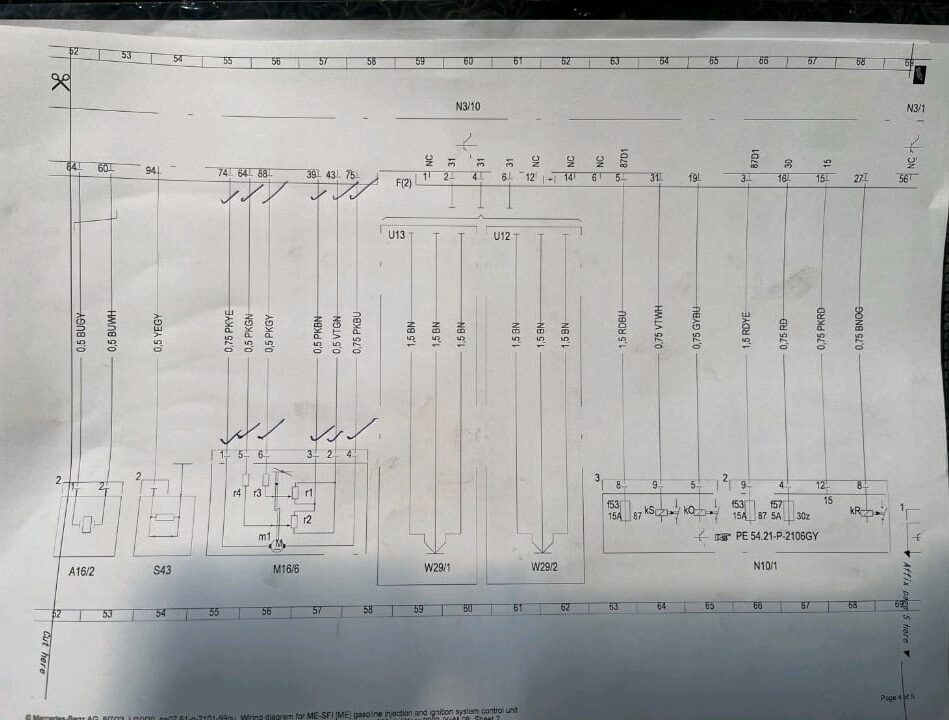

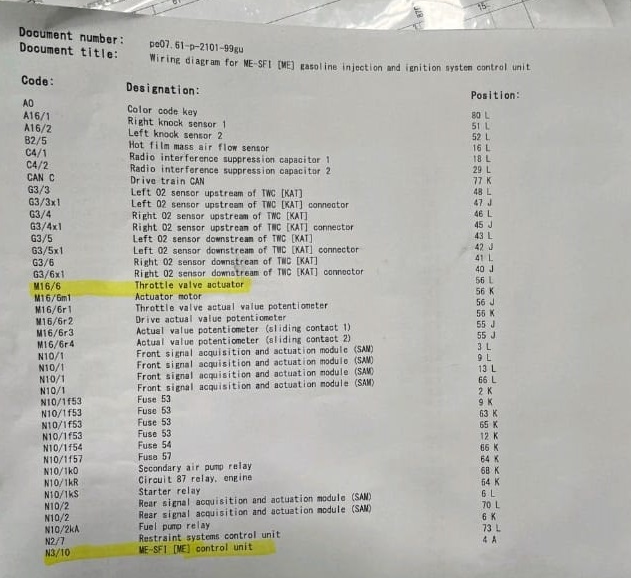

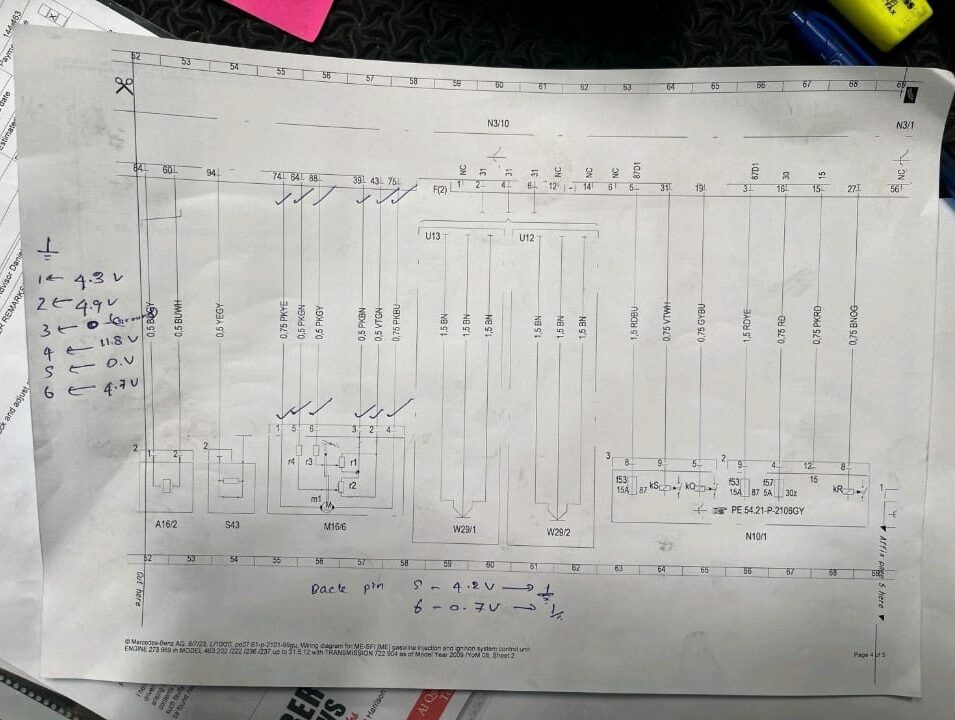

With the fault codes pointing towards the throttle valve actuator, we decided to perform further tests. Using the vehicle’s wiring diagram, we checked the power supply and wires’ resistance to ensure there was no electrical fault. Both the power supply and wiring tested as functional, indicating that the issue was likely mechanical.

We proceeded to carry out an actuation test on the throttle body to see if it would respond to commands. The throttle body did not respond, confirming a likely failure of the throttle valve actuator, which was preventing the car from accelerating.

The Solution: Throttle Body Replacement

After identifying that the throttle body was unresponsive, we made the decision to replace the throttle body, as it was clear that this component was no longer functioning correctly.

Once the throttle body was replaced, the issue was immediately resolved. The car now responded to throttle inputs without any hesitation, and the customer’s complaint that the car won’t accelerate was fully addressed. The vehicle was taken for a road test, where it demonstrated smooth and responsive acceleration.

Conclusion

This case study highlights the importance of proper diagnostic tools and methods when troubleshooting acceleration issues. The problem in this instance was directly tied to a malfunctioning throttle valve actuator, confirmed through fault codes and testing. Once the faulty component was replaced, the Mercedes-Benz G Class W463 returned to normal operation.

What happens when the throttle body fails?

When the throttle body fails, it can lead to a range of performance issues in your vehicle, particularly affecting acceleration and overall engine behavior. The throttle body is responsible for controlling the amount of air that enters the engine, which in turn regulates the engine’s power output. Here’s what happens when the throttle body fails:

Symptoms of Throttle Body Failure

1. Reduced or No Acceleration:

One of the most noticeable signs of a failing throttle body is poor or no response to acceleration. This occurs because the throttle body is unable to regulate the airflow into the engine, leading to a lack of power when you press the gas pedal.

2. Rough Idling or Stalling:

A malfunctioning throttle body can cause the engine to idle roughly or even stall because it is not receiving the correct amount of air. Inconsistent airflow can cause the engine to misfire or run unevenly.

3. Check Engine Light (CEL):

When the throttle body fails, the vehicle’s engine control unit (ECU) detects irregularities and may trigger the Check Engine Light. Diagnostic tools like OBD-II scanners can pull specific codes related to the throttle body, helping to pinpoint the issue.

4. Hesitation or Surging:

A failing throttle body can lead to hesitation during acceleration or sudden surges in speed, as the throttle valve may open and close unpredictably or become stuck.

5. Poor Fuel Efficiency:

With improper air intake, the engine’s air-fuel mixture becomes imbalanced, causing the engine to burn more fuel than necessary. This can lead to a noticeable decrease in fuel efficiency.

6. Unusual Noises:

A failing throttle body might produce whistling or sucking sounds due to air restriction or malfunction in the butterfly valve.

Causes of Throttle Body Failure

1. Carbon Buildup:

Over time, carbon deposits can accumulate inside the throttle body, obstructing the butterfly valve’s movement and leading to performance issues.

2. Electrical Issues:

The throttle body is electronically controlled in modern vehicles. If the electronic throttle actuator or sensors fail, the system may stop working correctly.

3. Mechanical Wear and Tear:

The moving parts inside the throttle body, such as the throttle plate, can wear out over time, leading to a loss of proper functionality.

Conclusion

A failing throttle body can cause significant drivability issues, including reduced acceleration, rough idling, and increased fuel consumption. If these symptoms occur, it’s crucial to diagnose and repair the throttle body to restore proper engine function.

How to check if the throttle body not working?

Checking if a throttle body is working correctly is crucial when diagnosing issues like poor acceleration, rough idling, or stalling. Here are several methods to check if the throttle body is functioning properly:

1. Visual Inspection

- Remove the Air Intake Hose:

Begin by disconnecting the air intake hose that connects to the throttle body. This will allow you to visually inspect the throttle body for any obvious issues, like dirt or carbon buildup. - Check for Carbon Buildup:

Excessive carbon deposits on the throttle plate or inside the throttle body can cause it to malfunction. If the throttle body is visibly dirty, it may not be opening and closing smoothly. - Inspect the Throttle Plate Movement:

With the engine off, manually move the throttle plate by pushing it open. It should move smoothly and spring back into place when released. If it sticks or moves erratically, this could indicate a problem.

2. Throttle Body Actuation Test

Using an advanced diagnostic tool like Xentry, OBD-II scanner, or similar systems, you can perform a throttle body actuation test. This checks if the electronic throttle actuator is responding correctly to inputs from the engine control unit (ECU).

- Connect the Diagnostic Tool:

Hook up the diagnostic tool to the vehicle’s OBD-II port and access the throttle system. - Perform the Actuation Test:

Using the diagnostic tool’s software, command the throttle body to open and close while the engine is off. If the throttle body does not respond, or if the movements are slow or irregular, the throttle body may be faulty.

3. Check for Fault Codes

- Use an OBD-II Scanner: Connect the OBD-II scanner to your vehicle’s diagnostic port and check for any stored fault codes. Common codes related to throttle body issues include:

- P2101: Throttle Actuator Control Motor Circuit Range/Performance

- P2112: Throttle Actuator Control System – Stuck Closed

- P0120 to P0124: Throttle/Pedal Position Sensor issues

- Clear Codes and Recheck:

If you find any throttle-related fault codes, you can clear them and retest the system. If the codes return after a short drive, it confirms there’s an issue with the throttle body.

4. Throttle Body Voltage Test

You can use a multimeter to check the electrical signals coming from the throttle position sensor (TPS) and the throttle actuator.

- Locate the Throttle Position Sensor (TPS):

This is usually integrated into the throttle body. Locate the wiring harness that connects to the TPS. - Measure Voltage:

With the engine on and the throttle closed, the TPS should show a low voltage (typically between 0.5V and 1V). As you press the accelerator pedal, the voltage should gradually increase, typically up to 4.5V to 5V at full throttle. - Check for Consistency:

If the voltage doesn’t increase smoothly or fluctuates, it may indicate a problem with the throttle position sensor or the throttle body.

5. Inspect Throttle Body Operation While Idling

- Start the Engine and Let It Idle:

Observe the engine’s idle speed and smoothness. A properly functioning throttle body should maintain a consistent idle. - Check for Rough Idle:

If the engine idles roughly or the RPM fluctuates, it could be a sign that the throttle body is not regulating airflow properly. - Rev the Engine:

While idling, gently rev the engine. The engine should respond smoothly to throttle inputs. If there’s hesitation or a delay in throttle response, the throttle body may not be working correctly.

6. Throttle Body Cleaning Test

If the throttle body has excessive carbon buildup, cleaning it might help restore its function. This is how you can check if cleaning the throttle body resolves the issue:

- Clean the Throttle Body:

Use a throttle body cleaner to remove carbon deposits and debris from the throttle plate and the inner housing. Make sure to follow the manufacturer’s guidelines for cleaning. - Reinstall and Test:

After cleaning, reinstall the throttle body and see if the performance improves. If the throttle body works correctly after cleaning, the issue was likely caused by carbon buildup.

— Salim, Mercedes Expert

Independent specialist in Mercedes-Benz diagnostics, CAN Bus analysis, troubleshooting case studies, and EV systems.

Leave a Reply