Table of Contents

Engine Cranking But Not Starting: A Diagnostic Case Study on Mercedes-Benz CLA W118

When your Mercedes-Benz engine cranks but doesn’t start, it can be frustrating especially when no fault codes appear. This case study on a Mercedes-Benz CLA W118 with the M282 engine explores a real-world scenario where the engine failed to start after the ECO Start/Stop function activated.

Through systematic diagnostics, we discovered a surprising cause a damaged dual mass flywheel (DMF) affecting the crankshaft position signal.

Customer Complaint: Engine Cranking But Not Starting

A customer reported that their CLA W118 wouldn’t start after paying a highway toll. The ECO Start/Stop system had turned the engine off as usual, but the car failed to restart, even after multiple attempts. The dashboard showed no specific warning, leaving the vehicle immobilized.

Initial Inspection

Upon receiving the car, we:

- – Connected a battery charger to ensure stable voltage.

- – Performed a quick diagnostic scan using XENTRY.

No engine control unit (ME) faults were detected, but the transmission control unit (TCU) recorded an error suggesting the engine had malfunctioned during a previous start attempt.

This pointed us toward an engine synchronization or signal issue rather than a fuel or ignition problem.

Step-by-Step Diagnostic Process

1. Data Analysis

Using live data from both engine and transmission control units, all measured values (voltage, RPM, fuel pressure) appeared normal during cranking prompting deeper mechanical and sensor checks.

2. Fuel System Verification

- – High-pressure fuel: OK

- – Low-pressure fuel: OK

Fuel delivery was consistent. No sign of fuel starvation or leak-back.

3. Ignition System Check

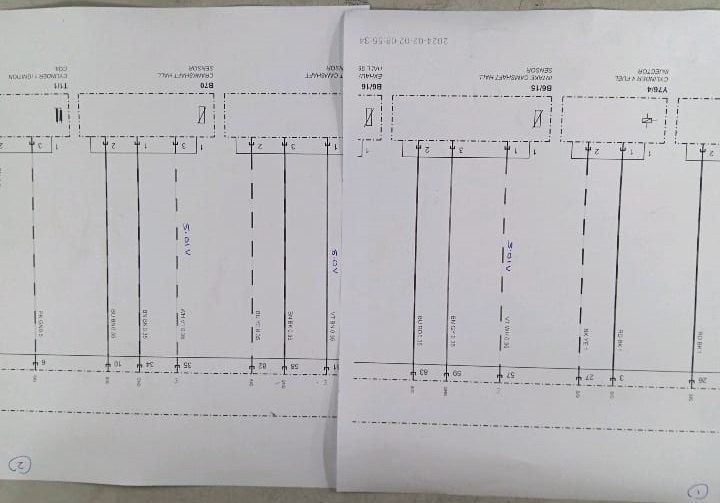

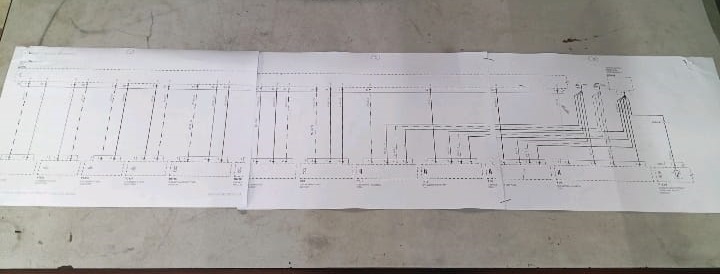

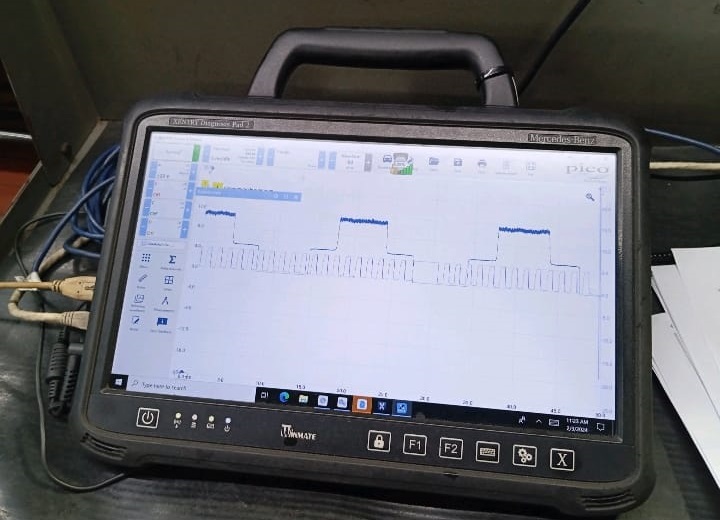

Using the WIS wiring diagram, we tested ignition coil signals with a PicoScope and multimeter:

- – 12V power supply : OK

- – 5V signal voltage : OK

- – Wave pattern : Stable and consistent

4. Injection Valve Testing

Signal voltages of all injection valves were measured during cranking; the waveforms matched the expected pulse timing.

→ Injection control system was functional.

5. Camshaft Sensor Evaluation

- – Intake and exhaust camshaft sensors received correct 5V reference signals.

- – Signal waveforms showed proper synchronization.

No fault here either.

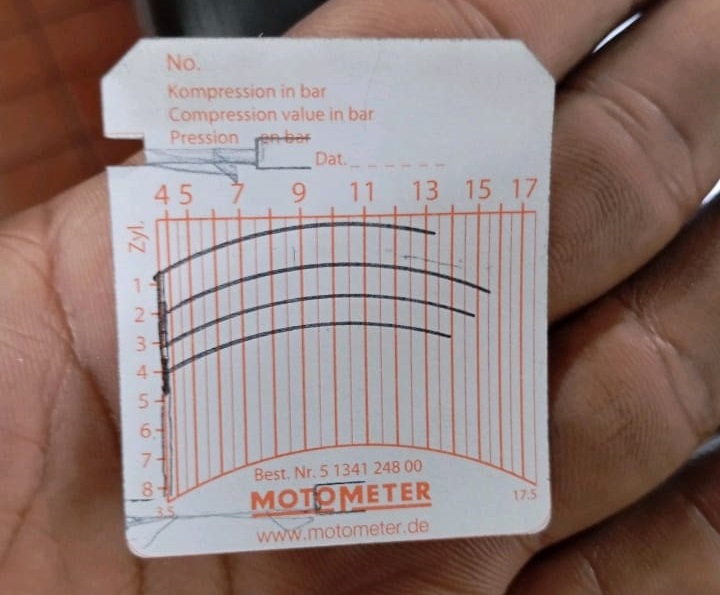

6. Crankshaft Position Sensor Investigation

While the crankshaft sensor’s power supply was normal, the signal waveform during cranking showed irregular amplitude spikes.

As a test, we removed the crankshaft sensor and attempted to crank again the engine started briefly after extended cranking, indicating signal distortion from mechanical interference rather than an electrical fault.

Deeper Inspection: The Hidden Culprit

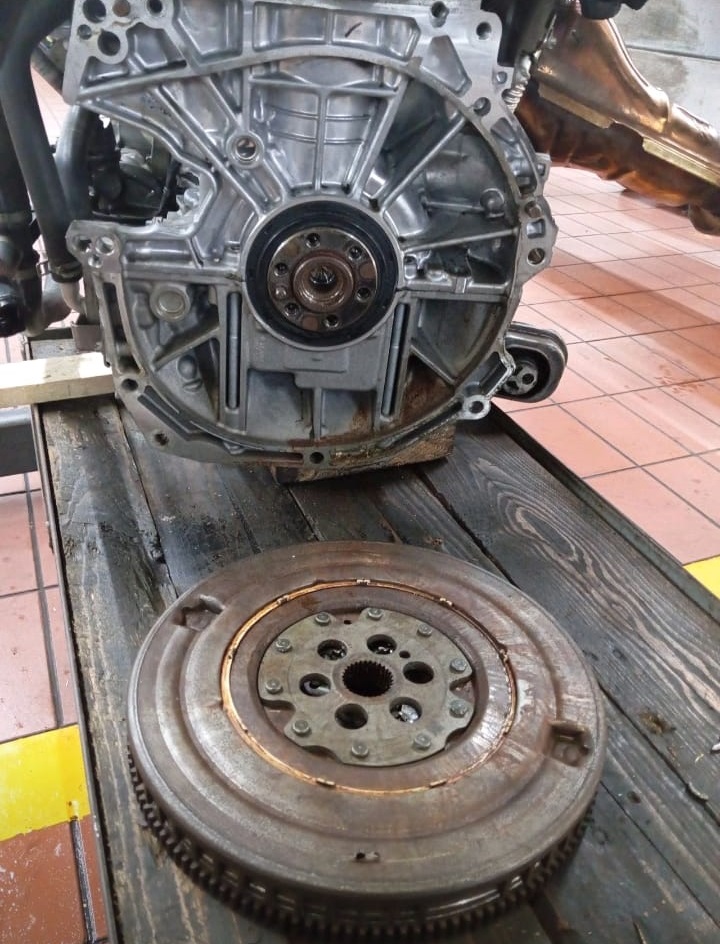

Using an endoscope, we inspected the flywheel’s incremental (pulse) wheel and found visible damage.

This damaged section was preventing the crankshaft position sensor from reading accurate rotation signals.

Repair Process

To confirm and repair:

- 1. Removed the engine and dual-clutch transmission.

- 2. Separated the engine from the gearbox.

- 3. Inspected the dual mass flywheel (DMF).

A fragment of the arc spring had broken loose and was moving within the bell housing — physically disturbing the pulse ring.

Solution: Replace the Dual Mass Flywheel (DMF).

After reassembly and testing, the vehicle started flawlessly, with no further fault codes or synchronization issues.

Understanding the Dual Mass Flywheel (DMF)

A Dual Mass Flywheel is designed to absorb engine vibrations and provide smoother drivetrain operation. It’s made of two masses connected by torsional springs.

Main Components

| Component | Function |

|---|---|

| Primary Mass | Connects to crankshaft and stores rotational energy. |

| Secondary Mass | Transfers torque to the transmission. |

| Torsional Springs | Absorb engine pulses to reduce vibration and drivetrain stress. |

How It Works

When the engine rotates, minor vibrations occur at low RPMs.

The DMF isolates these vibrations allowing smoother torque transfer between engine and gearbox.

However, if the internal springs or ring gear fail, it can disrupt sensor readings, leading to no-start or misfire conditions.

Pros & Cons of a Dual Mass Flywheel

| Advantages | Disadvantages |

|---|---|

| Reduces drivetrain vibration | Higher replacement cost |

| Improves comfort & shifting | Springs can fail over time |

| Extends gearbox life | Can cause hard-to-trace starting faults |

Conclusion

This case study demonstrates why thorough diagnostics are critical when facing an Engine Cranking But Not Starting issue.

Even though electrical and fuel systems appeared normal, the real fault stemmed from mechanical damage to the flywheel’s pulse ring.

Replacing the Dual Mass Flywheel fully resolved the no-start condition.

Related Diagnostic Resource

If you’re facing similar starting problems, explore our full troubleshooting hub:

Mercedes No Start Issues: Causes, Fixes & Case Studies : a complete guide covering electrical, fuel, and ECU-related no-start scenarios across multiple Mercedes models.

Prevention Tips

- – Avoid harsh clutch engagements that stress the DMF.

- – Replace engine mounts and crank sensors promptly when worn.

- – Use only OEM-spec flywheels and sensors.

- – Perform regular diagnostic scans after ECO Start/Stop events or unexpected stalls.

FAQ

1. Can a damaged flywheel cause a no-start problem?

Yes. A damaged incremental (pulse) wheel can distort the crankshaft sensor signal, preventing the ECU from initiating ignition.

2. Why did my car fail to start after ECO Start/Stop?

ECO systems rely on perfect timing signals. Any sensor or flywheel irregularity interrupts the restart cycle.

3. Is replacing a Dual Mass Flywheel expensive?

Yes, DMFs are costly due to their complex design, but they protect the gearbox and enhance comfort, making them worth replacing when faulty.

Author Bio

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last update: October 2025

Leave a Reply