Table of Contents

Case Study: Diagnosing and Fixing Engine Miss in a Mercedes-Benz E300 W212 (OM651)

An engine miss or misfire is one of the most common yet frustrating problems faced by vehicle owners. It can lead to poor idle quality, hesitation under acceleration, and a noticeable drop in engine performance.

In this real-world case, a Mercedes-Benz E300 W212 equipped with the OM651 Engine arrived at the workshop with a severe engine miss that persisted from idle through high RPMs.

For more verified misfire case studies and detailed troubleshooting procedures, explore the full guide at Mercedes Engine Misfire Issues: Causes & Fixes Hub.

Customer Complaint: Engine Miss and Hesitation at All RPMs

The owner reported that the vehicle was shaking and hesitating during acceleration and idle. The performance felt uneven, with noticeable loss of power and rough engine behavior.

Upon initial observation, the engine ran irregularly, confirming a significant combustion imbalance that required immediate diagnostic attention.

Step 1: Diagnostic Approach

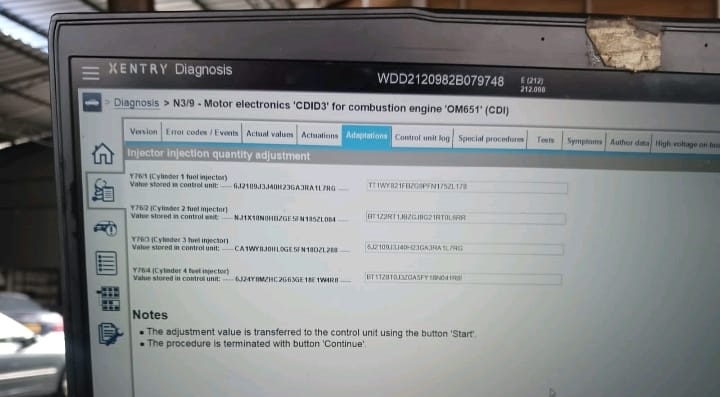

The technician began by performing a smooth running test using the Mercedes-Benz XENTRY diagnostic tool. This test helps identify which cylinders are not contributing properly to combustion.

Diagnostic Findings:

- – Cylinder Bank 1 and Cylinder Bank 4 showed insufficient fuel injection parameters, indicating poor combustion efficiency.

- – No fault codes related to ignition coils or sensors were present, suggesting the issue originated from the fuel delivery system rather than ignition.

Step 2: Detailed Inspection and Findings

To confirm the source of the problem, the technician conducted a comprehensive inspection of the injectors and performed an engine compression test.

Results:

- – Cylinder 1: The injector was severely worn, causing improper fuel atomization and incomplete combustion.

- – Cylinder 4: The injector hole was blocked by debris, restricting fuel flow and resulting in irregular combustion cycles.

These findings made it clear that the engine miss was caused by injector failure and contamination a combination that disrupted proper fuel-air mixing.

Step 3: Repair and Rectification Process

To restore smooth engine operation, the following repair steps were carried out:

1. Injector Replacement

The defective injector in Cylinder 1 was replaced with a new, OEM Mercedes-Benz injector to ensure correct spray pattern and flow rate.

2. Injector Hole Cleaning

The blocked injector port in Cylinder 4 was carefully cleaned to remove debris and restore proper fuel delivery.

3. Combustion Chamber Cleaning

All combustion areas were cleaned to eliminate carbon buildup that could affect injector seating and future combustion stability.

4. Recalibration via XENTRY

After installation, the fuel injection quantity and correction values were recalibrated to match the new injector characteristics. This ensured precise fuel delivery and smooth running across all cylinders.

Step 4: Post-Repair Verification

After the repair, the Mercedes-Benz E300 W212 underwent a final diagnostic test and test drive to verify performance.

Results:

- – No more engine hesitation or rough idle.

- – Smooth acceleration throughout the RPM range.

- – All injector parameters within specification.

- – No stored or pending fault codes.

The engine’s performance was fully restored, and the vehicle was returned to the customer the same day.

Key Takeaways for Technicians

- – Always confirm injector performance before replacement. Live data from XENTRY or equivalent diagnostic software can pinpoint weak or blocked injectors quickly.

- – Cleanliness is critical. Contamination in injector ports or combustion chambers can mimic electrical or sensor faults.

- – Recalibration is not optional. Every injector replacement must be followed by adaptation reset or calibration to ensure balanced fuel delivery.

- – Don’t overlook small misses. Minor hesitation often signals early-stage injector wear, which, if ignored, leads to costly repairs.

Conclusion

This Mercedes-Benz E300 W212 case study demonstrates how a simple engine miss can escalate into a severe drivability issue if left unchecked. The combination of a worn injector and blocked injector hole disrupted combustion across two cylinders, creating vibration, power loss, and poor idle quality.

A methodical diagnostic process rooted in injector testing, fuel system cleaning, and recalibration resolved the issue efficiently without unnecessary component replacements.

For more in-depth troubleshooting procedures, real-world case studies, and step-by-step repair workflows, explore the full resource hub here: Mercedes Engine Misfire Issues: Causes & Fixes Hub

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: November 2025

— Salim, Mercedes Expert

Independent specialist in Mercedes-Benz diagnostics, CAN Bus analysis, troubleshooting case studies, and EV systems.

Leave a Reply