Table of Contents

Case Study | Mercedes E300 Hybrid Problems: Engine No-Start Diagnosis (W212)

Hybrid Mercedes models like the E300 Hybrid W212 combine a conventional diesel engine with a high-voltage electric machine, a power electronics module, and an HV battery pack. When any of these systems malfunction, the vehicle may refuse to start even when the 12V battery is fully charged.

This case study breaks down a real diagnostic process from start to finish and demonstrates how a hidden fault inside the power electronics control unit (N129/1) caused a full no-start condition. It shows technicians and owners exactly how to troubleshoot similar Mercedes E300 Hybrid problems, especially when the engine will not start and no obvious mechanical symptoms are present.

Customer Complaint: Engine Not Starting on Mercedes E300 Hybrid W212

The owner reported:

- – Difficult starting over several days

- – Occasional refusal to start

- – No clear warning message

- – Hybrid system sometimes failing to enter “READY” mode

On hybrid Mercedes models, this issue may not behave like a typical diesel no-start. Instead, the system fails to synchronize both drivetrain systems and blocks the start procedure for safety.

Because hybrids rely heavily on electronic coordination, even a minor sensor fault can cause a complete engine no-start condition.

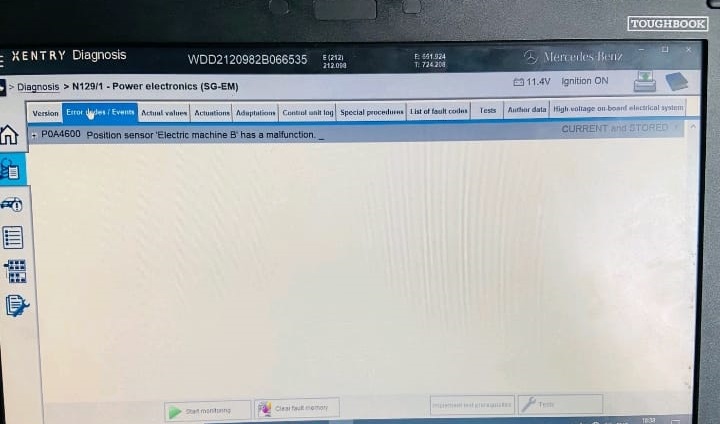

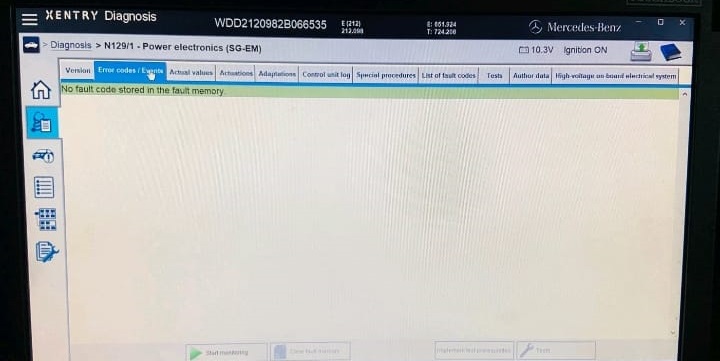

Step 1 : Full Hybrid Diagnostic Scan Using XENTRY

A complete scan of the hybrid system was performed.

The key fault code retrieved was:

➡ DTC P0A4600: Position Sensor “Electric Machine B” Malfunction

This sensor is part of:

- – The power electronics control unit (N129/1)

- – The electric motor’s internal position/rotor angle detection system

- – The hybrid synchronization process during starting and regenerative braking

If this sensor fails:

- – The electric machine cannot determine rotor position

- – The hybrid system cannot initiate torque blending

- – The system blocks the diesel engine from starting

- – High-voltage components may stay in a “Not Locked” state

This fault code is one of the most common root causes of

Mercedes E300 Hybrid Problems → Engine No-Start Symptoms.

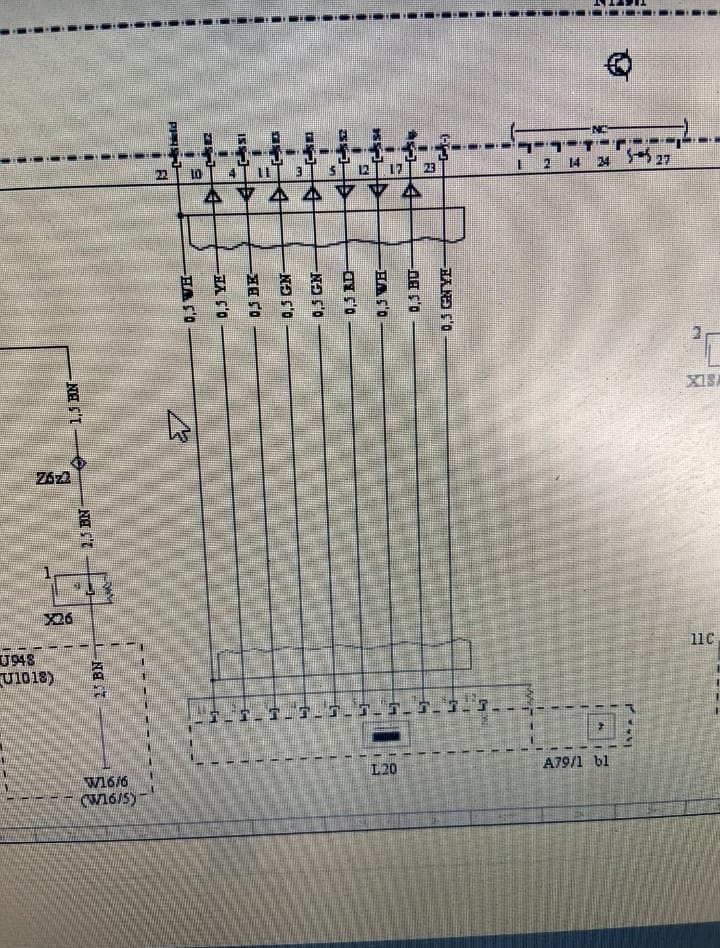

Step 2 : Wiring Diagram Verification & Power Supply Checks

Before replacing hybrid components, the technician verified:

✔ Power Supply to N129/1 : Normal

Voltage supply stable on load tests.

✔ CAN Communication : OK

No interruptions or communication loss with the hybrid module.

✔ Sensor Wiring : Continuity OK

Resistance readings confirmed no short circuit or open circuit.

✔ No Corrosion or Mechanical Damage

All terminals and connectors were inspected carefully.

These checks ruled out the easiest causes, confirming the problem was internal to the hybrid control system rather than a wiring or 12V issue.

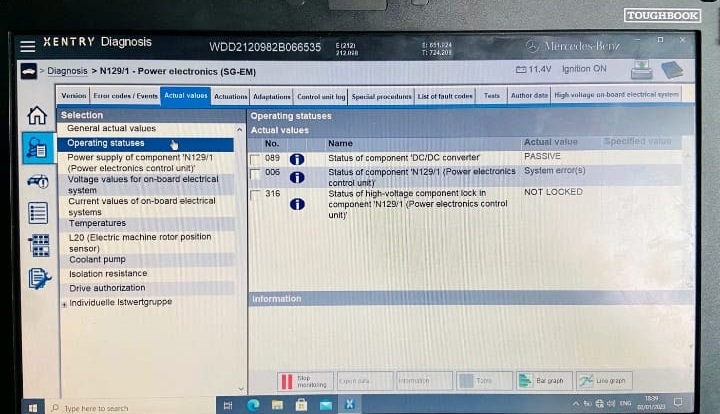

Step 3 : Hybrid System Actual Values: Critical Clues

The live data revealed:

- – Power Electronics Control Unit Status: SYSTEM ERROR

- – High-Voltage Component Lock: NOT LOCKED

- – Rotor Position Value: Implausible / No Signal

These results are typical when the position sensor has failed inside the hybrid power electronics unit.

This is also why many E300 Hybrid vehicles refuse to start without showing a clear dashboard warning the system detects a safety risk in the high-voltage circuit.

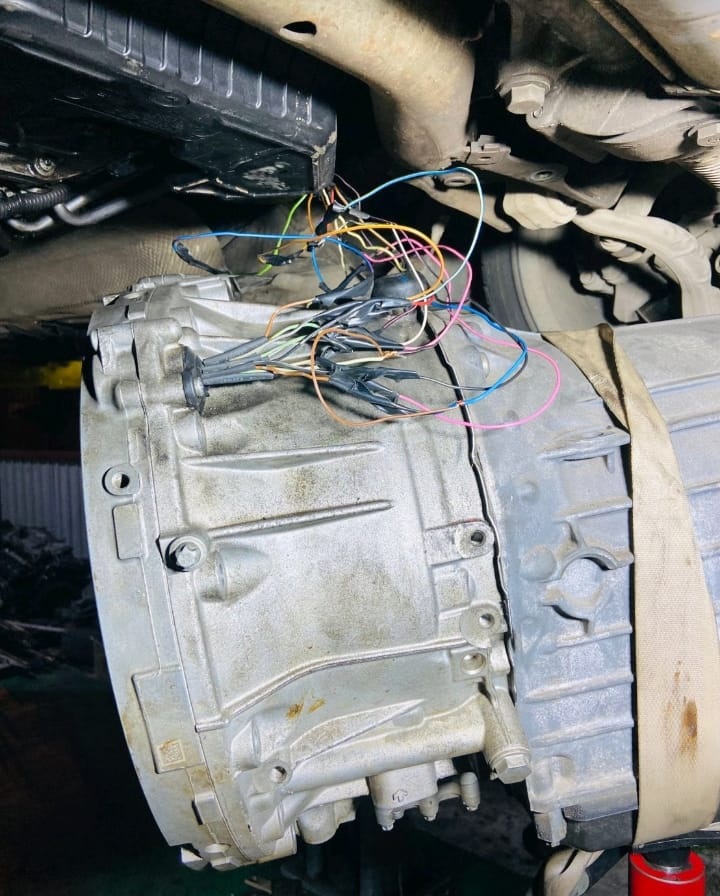

Step 4 : The Repair; Replacing the Hybrid Position Sensor

Based on:

- – Fault code P0A4600

- – Implausible actual values

- – Good power supply

- – Healthy wiring

- – HV system status errors

the position sensor was confirmed as the root cause.

The defective rotor position sensor was replaced.

After installation:

- – The high-voltage system locked correctly

- – The vehicle entered READY mode immediately

- – The engine started smoothly without hesitation

- – All hybrid system values stabilized

- – No fault codes returned

- – Combustion engine and electric motor synchronized perfectly

This fully resolved the engine no-start condition.

Final Results & Key Lessons

This real case of Mercedes E300 Hybrid Problems shows why hybrid no-start conditions require deep diagnostic logic not guesswork.

Key Takeaways

1. P0A4600 = High-Risk Hybrid No-Start Code

Any issue with rotor position sensing blocks hybrid synchronization.

2. Wiring test alone is not enough

Power supply and continuity can test perfectly, but the sensor may still be internally defective.

3. A hybrid “SYSTEM ERROR” means: investigate high-voltage components first

Hybrid operation depends on precise electronic coordination.

4. Proper diagnostic workflow avoids unnecessary parts replacement

This vehicle could have easily suffered misdiagnosis of:

- – 12V battery

- – starter motor

- – HV battery

- – DC/DC converter

Instead, the correct single component was replaced.

5. Hybrid training and HV safety procedures are mandatory

These repairs cannot be approached like a standard diesel no-start.

Conclusion : A Classic Example of Hybrid No-Start Logic

The no-start issue in this Mercedes E300 Hybrid W212 was fully resolved by replacing a faulty electric machine position sensor, located within the power electronics control unit.

This case reinforces the importance of:

- – Guided diagnostics

- – Understanding hybrid architecture

- – Reading actual values (not just fault codes)

- – Checking HV interlock status

- – Confirming power electronics health

For technicians and owners facing similar Mercedes E300 Hybrid Problems, this case directly demonstrates how hybrid systems behave when the electric machine can’t determine rotor angle and why the engine will not start until the issue is repaired.

Author Bio

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last update: November 2025

Leave a Reply