Table of Contents

Mercedes Not Starting: A Case Study on the Mercedes CLA 118 with M282 Engine

When your Mercedes won’t start, it can be both stressful and unexpected especially when it happens suddenly with no prior warning. In this case study, we’ll take a detailed look at a Mercedes-Benz CLA 118 equipped with the M282 engine, which arrived at the workshop with a no-start condition.

Using professional Mercedes XENTRY diagnostics, our technicians uncovered the true cause a contaminated Powertrain Control Unit (PCU) that had shorted internally.

Let’s walk through the full process, step-by-step.

Customer Complaint: Mercedes Not Starting

The customer reported that their Mercedes CLA 118 was completely unresponsive. The engine would not start, and all attempts to crank failed. The breakdown occurred suddenly, leaving the driver stranded and requiring towing to the workshop.

1. Diagnostic Overview with XENTRY

As with all Mercedes-Benz diagnostic procedures, the first step was to connect the XENTRY diagnostic tool to scan for communication faults.

The scan revealed a major issue:

All control units within the “DRIVETRAIN CAN” system were showing communication loss.

This meant that the engine, transmission, and related modules were unable to communicate a critical fault that can completely prevent the vehicle from starting.

2. Step-by-Step Investigation

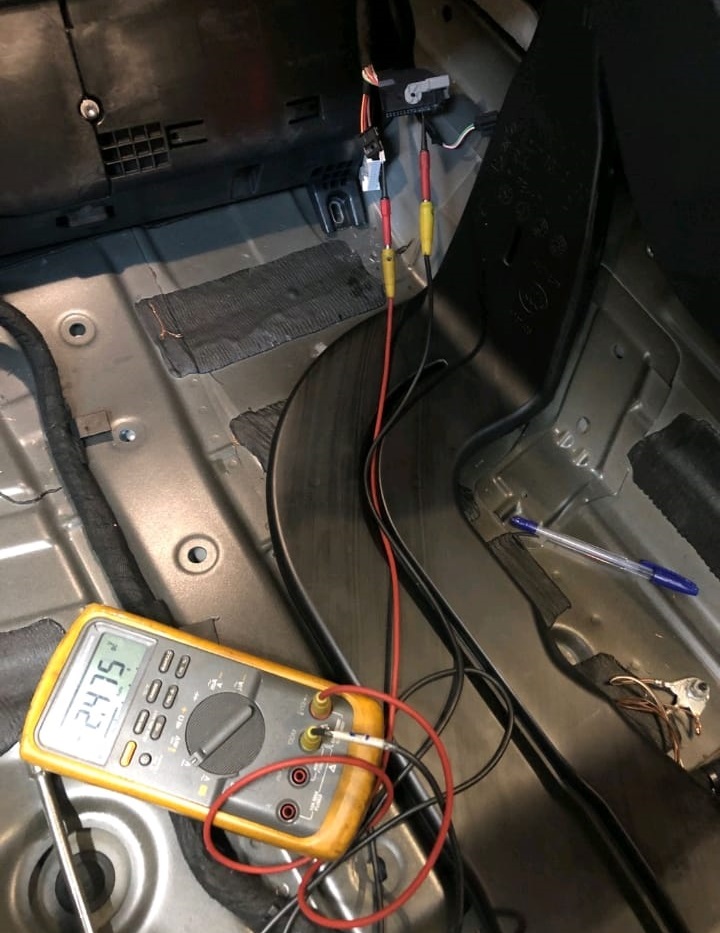

Supply Voltage Check

We measured the supply voltage to the Powertrain Control Unit (PCU).

The readings were below specification, confirming a power distribution problem within the drivetrain system.

CAN Line Inspection

Next, we checked the CAN high and CAN low lines for continuity and physical damage.

- – Both lines were intact and free of breaks or short circuits.

- – CAN bus resistance was measured at 60Ω, confirming network integrity.

Therefore, the communication fault was not caused by the CAN wiring.

Wiring Harness & Rodent Damage

During visual inspection, we noticed rodent damage in part of the wiring harness.

However, after continuity testing, it was confirmed this damage was unrelated to the no-start issue an important distinction that prevented unnecessary repairs.

Fuse Box Inspection

Next, we inspected the main fuse box and discovered a damaged fuse in the power supply line to the Powertrain Control Unit.

A blown or corroded fuse can interrupt module communication and voltage delivery.

After replacing the fuse, the PCU still failed to wake up indicating internal failure rather than an external short.

PCU Contamination & Root Cause

Upon further investigation, we found water contamination inside the Powertrain Control Unit (located under the engine bay).

The moisture caused internal corrosion and a short circuit, effectively disabling the entire drivetrain communication network.

This was the primary cause of the Mercedes not starting.

3. Rectification & Repair

To restore proper communication and starting operation:

- 1. The Powertrain Control Unit was replaced with a genuine Mercedes-Benz part.

- 2. The replacement unit was coded and adapted using XENTRY.

- 3. The fuse and connector terminals were cleaned and sealed to prevent future moisture ingress.

After completing the repair and reprogramming, the engine started immediately.

A final system scan confirmed all drivetrain modules were communicating correctly.

Result: The “Mercedes Not Starting” issue was completely resolved.

4. Understanding the Powertrain Control Module (PCM / PCU)

The Powertrain Control Module (PCM) also known as the PCU in Mercedes is a critical ECU that manages the engine, transmission, and emissions systems.

Key Functions of the PCM:

| Function | Description |

|---|---|

| Engine Management | Controls fuel injection, ignition timing, and air-fuel ratios. |

| Transmission Control | Determines gear shifts based on load and speed. |

| Emission Control | Regulates air/fuel ratio to meet emission standards. |

| Diagnostics | Stores and communicates fault codes to the diagnostic system. |

| CAN Communication | Coordinates with other modules like ABS, ESP, and SAM for system integration. |

If this module fails whether from electrical overload or water ingress the vehicle can experience no-start conditions, erratic shifting, or even limp mode.

5. Common Symptoms of a Bad Powertrain Control Module

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | No communication between ECU and ignition system |

| Check Engine Light always on/off | PCM signal failure or internal short |

| Transmission shifting issues | Communication loss with transmission control module |

| Intermittent stalling | Incorrect sensor data processing |

| Rough idle or poor fuel economy | Incorrect air-fuel ratio control |

| Electrical malfunctions | Faulty internal circuits or corroded connectors |

A faulty PCM can mimic multiple unrelated system failures, so proper diagnostics are essential before replacement.

6. Final Verification

After replacing the PCU:

- – The vehicle started normally.

- – Communication was restored across the DRIVETRAIN CAN.

- – A post-repair test drive confirmed stable shifting, no fault codes, and normal performance.

This case highlights the importance of thorough electrical and communication testing not just visual inspections when diagnosing a Mercedes not starting condition.

7. Related Diagnostic Resource

If you’re facing similar starting problems, explore our full troubleshooting hub:

Mercedes No Start Issues: Causes, Fixes & Case Studies : a complete guide covering electrical, fuel, and ECU-related no-start scenarios across multiple Mercedes models.

8. Prevention Tips

- – Seal ECU connectors and engine bay harnesses after repairs.

- – Avoid pressure washing near electrical control modules.

- – Inspect fuses regularly for signs of corrosion.

- – Park indoors if possible to reduce moisture exposure.

- – Use anti-rodent protective spray on wiring if in rodent-prone areas.

FAQ

1. What causes the Powertrain Control Unit to fail?

Water ingress, electrical short circuits, or voltage spikes are the most common reasons for PCU failure.

2. Can a bad PCM cause a Mercedes not to start?

Yes. A faulty PCM/PCU interrupts communication between ignition, fuel, and transmission systems, resulting in a no-start condition.

3. How can I prevent PCM damage?

Regularly inspect seals, grommets, and ECU covers for leaks and moisture buildup.

Author Bio

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last update: October 2025

Leave a Reply