Table of Contents

Oil in Coolant Issue in Mercedes-Benz CLA W118 with M282 Engine – Case Study

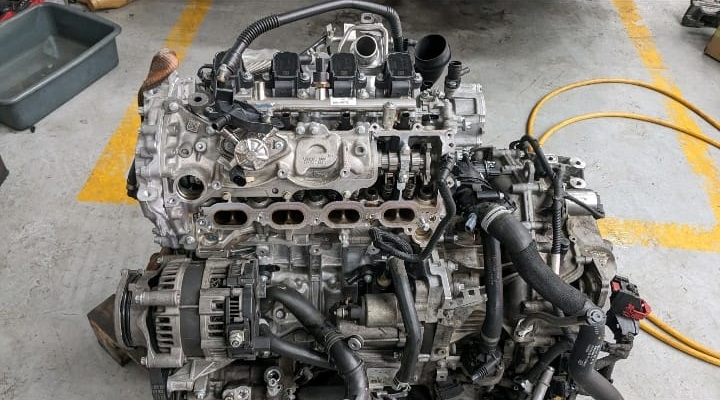

Vehicle: Mercedes-Benz CLA W118

Engine: M282 Engine

Complaint: Oil Mixing with Coolant

Finding oil in coolant is one of the most alarming issues for any car owner, especially in a high-performance vehicle like the Mercedes-Benz CLA W118 with the M282 engine. This problem can cause engine overheating, poor lubrication, reduced performance, and eventually catastrophic engine failure if ignored.

In this case study, we will cover:

- – FAQs with practical answers for Mercedes owners

- – How the issue was diagnosed step by step

- – The common symptoms, causes, and fixes of oil in coolant

- – The repair process carried out on this vehicle

- – Preventive measures to avoid future damage

Symptoms, Causes, and Fixes

| Symptoms | Possible Causes | Fixes |

|---|---|---|

| Milky or brown coolant in reservoir | Failed head gasket | Replace head gasket and check cylinder head |

| Overheating engine | Oil cooler leak or gasket failure | Inspect/replace oil cooler and seals |

| Oil residue in coolant hoses | Cracked cylinder head or block | Machine/replace cylinder head or block |

| White smoke from exhaust | Coolant entering combustion chamber via gasket | Replace head gasket, resurface head if needed |

| Reduced engine performance | Contaminated cooling and lubrication system | Flush coolant system, replace oil, refill fresh fluids |

| Warning lights on dashboard | Cooling system malfunction detected | Perform diagnostic scan and address fault codes |

Diagnostic Steps

1. Visual Inspection

- – Checked coolant reservoir: coolant appeared milky with traces of oil.

- – Verified oil dipstick: no coolant present in engine oil (ruled out cross-contamination both ways).

2. Source Verification

- – Determined whether contamination came from engine oil or gearbox oil.

- – Confirmed engine oil was the contaminant.

3. Oil Cooler Check

- – Inspected the engine oil cooler for cracks or leaks.

- – Result: cooler in perfect condition, no oil intrusion.

4. Head Gasket Testing

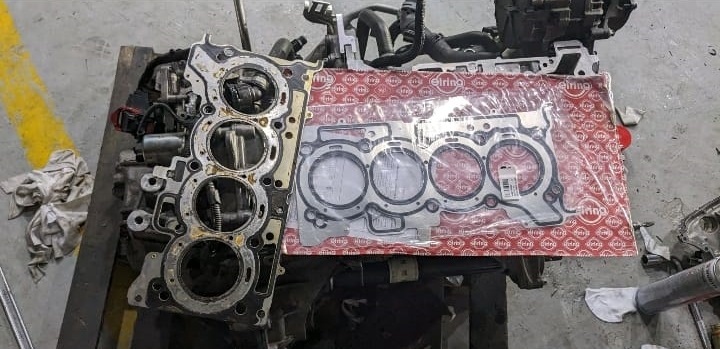

- – Removed cylinder head for inspection.

- – Found a blown head gasket, allowing engine oil into the coolant passages.

5. Cylinder Head Inspection

- – Sent head to a lathe shop to check for warping or cracks.

- – Confirmed it was within tolerance.

Repair Process

Replaced Head Gasket: Installed a new, genuine Mercedes gasket.

Once the faulty gasket was identified, we sent the engine head to a lathe shop for inspection. This step ensures that the head is not warped or damaged, which could cause a new gasket to fail prematurely. After receiving the green light from the lathe shop, we installed a new gasket and reassembled the engine.

Cleaned Cooling System: Flushed coolant thoroughly to remove oil residue.

Before reinstalling the engine, we thoroughly cleaned the coolant system to remove any residual oil. This step is vital to prevent future contamination and ensure the cooling system operates efficiently. After cleaning, we reinstalled the engine and filled the coolant with fresh fluid.

Checked & Reassembled Engine: Ensured correct torque specifications when reassembling.

Refilled with Fresh Fluids: Replaced coolant and engine oil to restore system integrity.

Prevention Tips

To prevent oil in coolant issues in Mercedes CLA W118 with the M282 engine:

- – Monitor Engine Temperature: Overheating accelerates gasket wear.

- – Use Genuine Parts: Always use OEM oil coolers and gaskets.

- – Regular Coolant Flush: Prevents contamination buildup.

- – Timely Oil Changes: Reduces sludge that can damage seals and gaskets.

- – Professional Inspections: At the first sign of overheating or coolant discoloration, seek diagnosis.

Conclusion

The oil in coolant issue in this Mercedes-Benz CLA W118 with M282 engine was caused by a failed head gasket. By systematically diagnosing, confirming the fault, replacing the gasket, and flushing the system, the problem was resolved.

This case emphasizes that early detection is crucial. Ignoring oil in coolant can result in overheating, engine failure, and costly repairs.

More Mercedes Cooling System Resources

Want to explore more causes, symptoms, and repair tips for coolant leaks, overheating, and contamination?

Learn more about Mercedes cooling system faults in our full Cooling System Guide.

FAQs

Q1: Is it safe to drive with oil in the coolant?

No. Driving with oil-contaminated coolant risks overheating and permanent engine damage.

Q2: How do I know if my head gasket has failed?

Common signs include milky coolant, overheating, white smoke from the exhaust, and loss of engine power.

Q3: Can oil in coolant come from something other than the head gasket?

Yes. It can also come from a faulty oil cooler, cracked cylinder head, or engine block damage.

Q4: How much does it cost to fix oil in coolant in a Mercedes CLA?

Costs vary but can range from $1,200–$3,000, depending on the extent of damage and parts replaced.

Q5: Should I flush my coolant system after a head gasket replacement?

Absolutely. Flushing is mandatory to remove residual oil and protect the new gasket.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

— Salim, Mercedes Expert

Independent specialist in Mercedes-Benz diagnostics, CAN Bus analysis, troubleshooting case studies, and EV systems.

Leave a Reply