Table of Contents

Mercedes Fault Code P2767: Diagnose & Fix Gear-Shifting Issues

P2767 isn’t just another code it’s your Mercedes telling you the turbine (input) speed signal is missing/implausible. Without a clean turbine speed signal, the transmission control module (TCM/EGS) can’t time clutch fills or overlap accurately, so you feel hard shifts, banging into gear, flare, or limp mode.

This guide explains what P2767 means, how to diagnose it step-by-step, and how we fixed it on a C-Class with the M271 engine + 5G-Tronic plus practical tables, costs, and FAQs.

Quick Facts (What P2767 Means)

| Item | Detail |

|---|---|

| Code | P2767: Turbine/Input speed sensor (often “RPM sensor 2”/“turbine wheel”) no signal/implausible |

| What fails | The speed sensor or its driver/wiring; on many Mercedes, the sensor is integrated (not separately serviceable) |

| Typical result | Harsh shifts, gear banging, delayed engagement, possible limp mode |

| Common fix | Replace the electro-hydraulic unit (mechatronics/valve body or conductor plate, depending on transmission), then adaptations |

Note on transmission families

- – 5G-Tronic (722.6): turbine/output speed sensors are built into the conductor plate.

- – 7G/9G-Tronic (722.9/725.0): sensors are integrated in the VGS/mechatronics.

Always confirm by VIN/WIS which assembly your car uses.

Symptoms & First Clues

| Symptom | Why it happens |

|---|---|

| Hard or banging shifts | TCM can’t see turbine speed → wrong pressure/overlap timing |

| Delayed or harsh engagement into D/R | Input speed unknown → fill timing off |

| Limp mode, limited gears | Protective strategy to prevent damage |

| MIL/Transmission warning | DTC stored for missing/implausible turbine speed |

Case Study: C-Class (M271) with 5G-Tronic: Hard Shifts & Banging

Complaint: harsh gear changes and loud “bangs” during upshifts/downshifts.

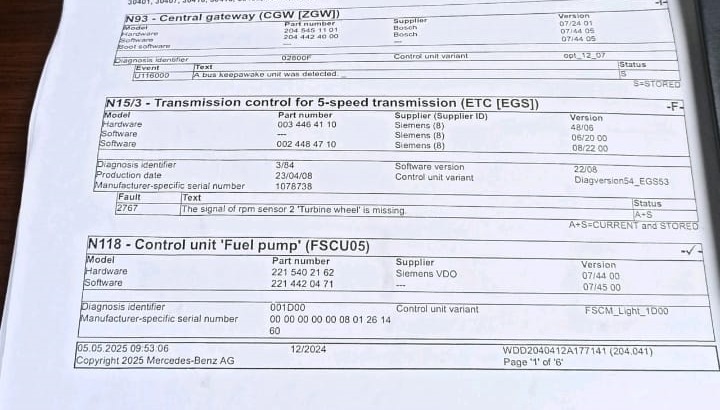

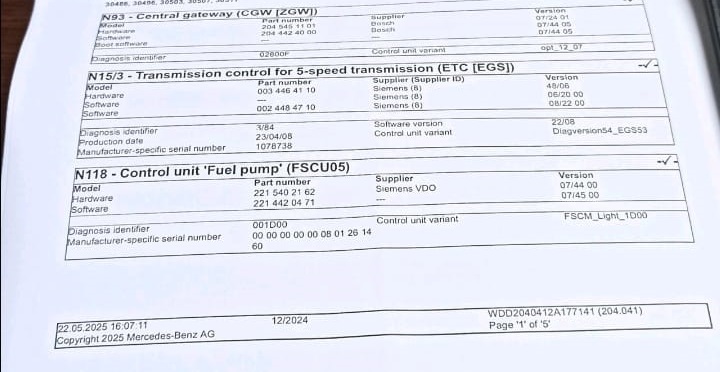

Scan (XENTRY): P2767 – missing signal from RPM sensor 2 (turbine wheel). No other hard faults.

Guided test outcome: Wiring/connector checks were OK. XENTRY recommended replacing the electro-hydraulic unit for this transmission family (sensor integrated).

Diagnostic Workflow (Do This in Order)

1. Full short test (OE level)

Read TCM/EGS, engine, ESP. Save freeze frames. Confirm P2767 current (not stored).

2. Preconditions

- – Battery/charging: 12.5–14.5 V stable (connect maintainer).

- – ATF temperature within spec for level checks & adaptations.

3. Visuals & connectors

Inspect transmission plug/13-pin connector for fluid wicking, corrosion, bent pins, water ingress. Repair as needed.

4. Wiring sanity

If accessible per WIS: continuity and insulation tests between TCM and the speed-sensor pins. (On many models, sensors are inside the mechatronics; don’t pierce harness.)

5. Live data

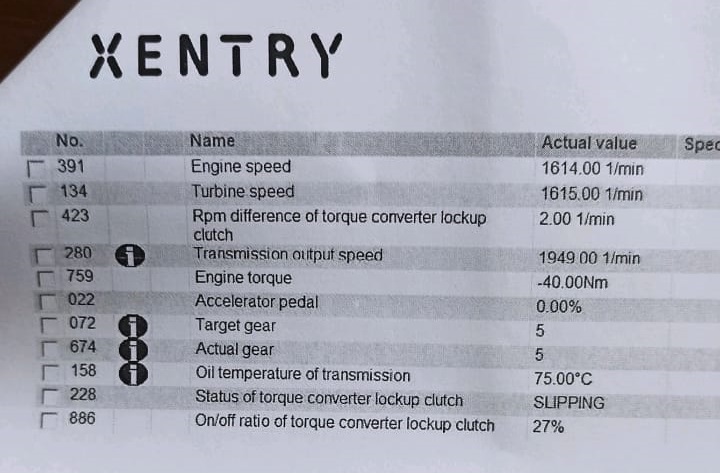

Watch turbine speed vs. engine speed while gently raising RPM in D (brakes firmly applied).

- – If turbine speed stays zero/erratic and wiring is fine → suspect integrated sensor/mechatronics.

- – If turbine and engine speeds correlate intermittently → suspect connector/loom.

6. Decision

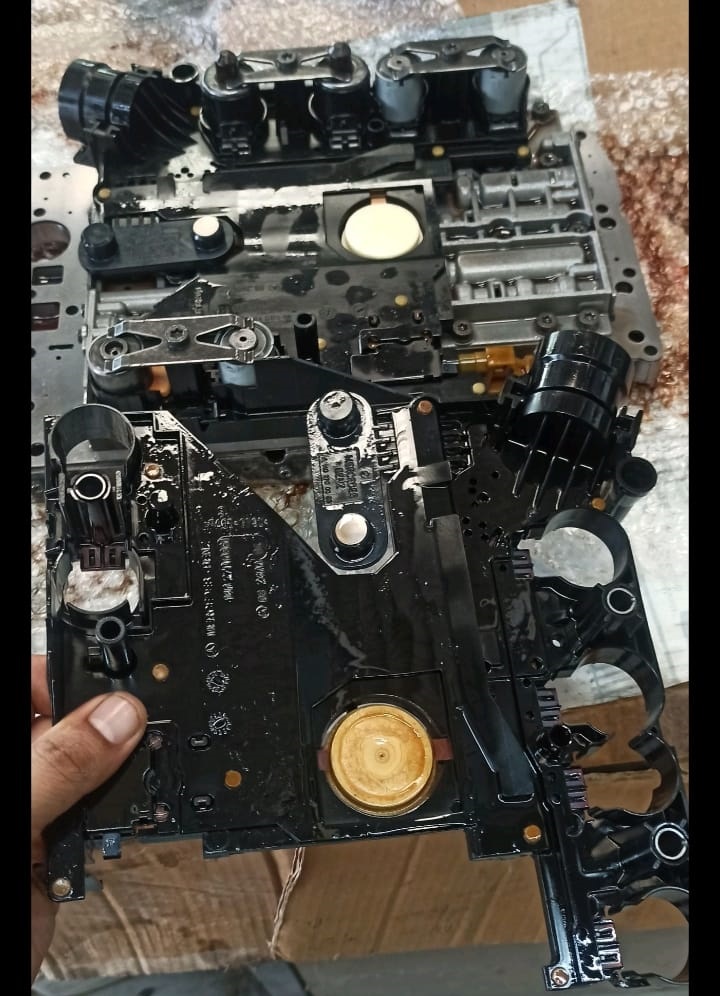

- – 5G-Tronic (722.6): replace conductor plate (often with pilot bushing/connector sleeve).

- – 7G/9G-Tronic (722.9/725.0): replace VGS/mechatronics.

Follow WIS for torque sequences, coding, fluid spec, and cleanliness protocols.

7. Adaptations & validation

Perform standstill & running adaptations. Road test; recheck for codes. Log shift events and turbine/internal/output speeds.

Symptom → Likely Cause → Fix

| Symptom | Likely Cause | What to Do |

|---|---|---|

| Turbine speed 0 rpm all the time | Failed internal sensor; mechatronics fault | Replace conductor plate/VGS per model; adaptations |

| Intermittent turbine speed dropouts | Connector fluid ingress, pin tension, loom fault | Clean/repair connector, replace sleeve, re-pin if needed |

| Still bangs after repair | Adaptations not completed; ATF level off | Re-run adaptations with correct ATF temp; verify level |

| Limp mode with multiple sensor codes | Low voltage, ground issues | Stabilize power/grounds; clear codes; retest |

Explore More Mercedes Transmission Issues

For a deeper dive into gearbox problems slipping into Neutral, delayed/harsh shifts, “Not in P” warnings, and hybrid faults visit our hub: Mercedes Transmission Issues – Causes and Fixes. You’ll find grouped case studies, step-by-step diagnostics, symptom–cause–fix tables, and prevention tips to resolve shifting issues quickly and confidently.

Tools & Preconditions

| Category | Requirement |

|---|---|

| Diagnostics | XENTRY or OE-level scan tool for guided tests & adaptations |

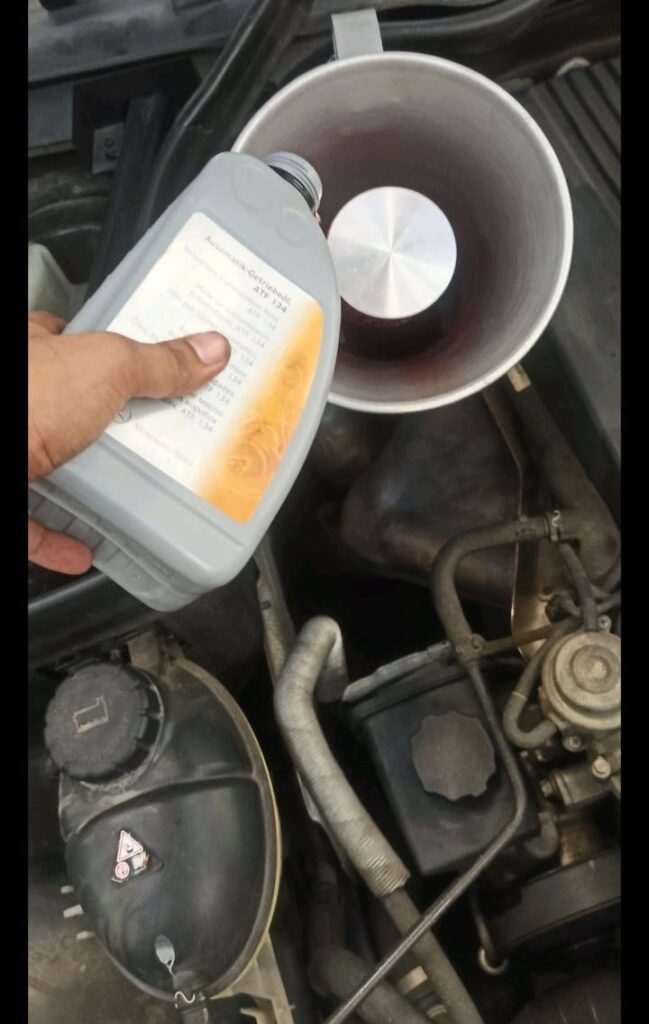

| Fluids | MB-approved ATF for your gearbox; new filter/pan gasket |

| Electrical | Battery maintainer; avoid low-voltage during procedures |

| Information | WIS/ASRA for diagrams, torque specs, and fill procedures |

| Safety | Hot ATF & under-car work use PPE, stands, and wheel chocks |

Repair Steps (Typical)

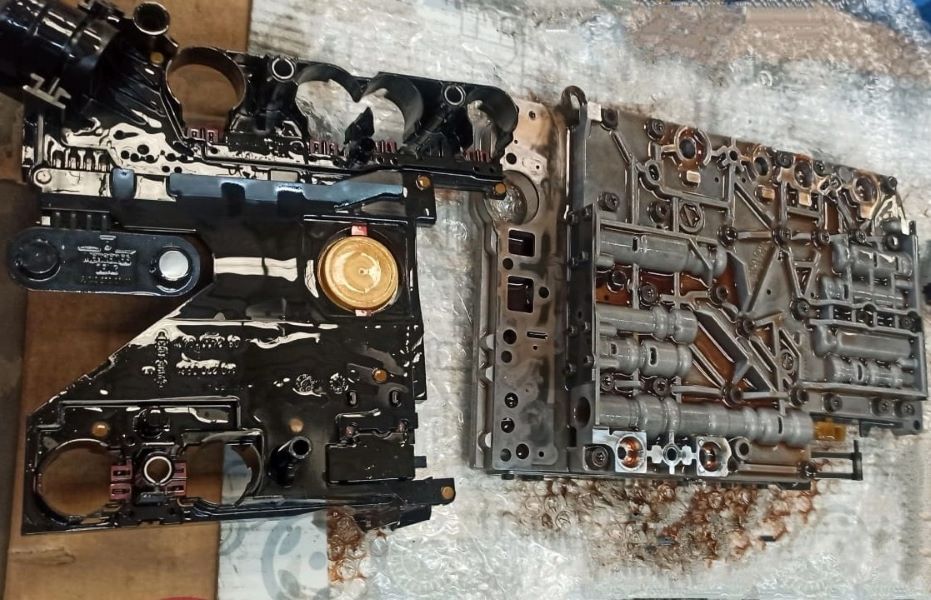

- 1. Drain & remove pan, discard filter and gasket.

- 2. Inspect debris on magnet & filter excess metal may suggest additional issues.

- 3. Remove mechatronics/conductor plate per WIS; disconnect carefully to avoid pin damage.

- 4. Install new unit (genuine/OE-quality), renew connector sleeve, seals, and bolts.

- 5. Refit filter & pan; fill with correct ATF; run through gears; set level at temp.

- 6. Clear DTCs; run standstill/running adaptations precisely as prompted.

- 7. Road test with logs; recheck for leaks and final code scan.

Costs & Time

| Operation | Typical Time | Cost Drivers |

|---|---|---|

| Diagnosis & live-data logging | 1.0–1.5 h | Shop rate, replication time |

| Mechatronics/conductor plate R&R | 2.5–4.0 h | Model packaging, seized fasteners |

| ATF/filter/pan service | 0.8–1.2 h | ATF spec & quantity, parts quality |

| Adaptations + road test | 0.5–1.0 h | Traffic/ambient temp |

Parts: conductor plate/mechatronics assemblies vary widely; total $800–$1,800 (parts+labor) is common, region-dependent.

Prevention & Best Practices

- – Service ATF & filter on sensible intervals (many specialists: 60–80k km / 4–5 years), even if “lifetime.”

- – Fix minor shift harshness early don’t wait for banging and limp mode.

- – Keep battery/charging healthy; low voltage corrupts sensor diagnostics and adaptations.

- – After module or plate replacement, always run adaptations with the exact preconditions (ATF temp, voltages, no pending DTCs).

Live-Data Decoder

| Channel | Healthy Behavior | Red Flags |

|---|---|---|

| Turbine speed | Tracks engine speed proportionally at stall; responds to throttle in D | Flat 0 rpm, random spikes, or dropouts |

| Output speed | Correlates with vehicle speed | Stays 0 while moving (sensor/output path issue) |

| Gear actual vs. target | Matches requested with small delay | Frequent mismatch or harsh corrections |

DIY vs Professional

| Task | DIY | Pro |

|---|---|---|

| Read/clear basic codes | OK | |

| Check ATF level/condition* | OK | |

| Replace connector sleeve (if equipped) | OK | |

| Replace conductor plate/VGS | OK | |

| Perform adaptations (XENTRY) | OK |

*Only if you know the temperature-based level procedure for your gearbox.

FAQs

1) What exactly triggers P2767?

A missing/implausible turbine speed signal. The TCM can’t compute clutch timing, so it hard-shifts or goes limp. Causes include a failed integrated sensor, internal mechatronics fault, or connector/wiring issues.

2) Can I just clear the code?

You can, but it will return if the signal is still bad. Always fix the cause (mechatronics/plate or wiring) and then clear codes.

3) Do I always need a whole valve body?

Not always. On 722.6 you typically replace the conductor plate (with speed sensors). On 722.9/725.0, the sensor is part of VGS/mechatronics. Verify by VIN.

4) Will a fluid change fix P2767?

Fresh ATF can improve shift feel, but it won’t restore a dead sensor. If P2767 is current and live data shows zero/erratic turbine speed, address the sensor/mechatronics.

5) Why are adaptations necessary after repair?

The TCM must relearn clutch fills and overlap timing. Skipping adaptations can leave you with harsh shifts even after correct parts are installed.

6) Is it safe to keep driving with P2767?

Not recommended. Harsh shifts stress clutches and can escalate costs. Diagnose and repair promptly.

7) What else should be replaced during repair?

At minimum: filter, pan gasket, connector sleeve/seals, and ATF to spec. Inspect the magnet and pan for metal debris.

8) My car has multiple speed sensor codes what then?

Check battery/grounds first. If voltage is good, suspect broader mechatronics issues or contaminated connectors; follow guided tests before replacing assemblies.

Conclusion

P2767 is a classic turbine speed signal failure. Verify power/grounds and connectors, confirm with live data, then replace the correct integrated assembly (conductor plate or mechatronics) for your transmission family. Finish with proper ATF service and adaptations. Done right, shift quality returns to factory-smooth and stays that way.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: September 2025

Leave a Reply