Table of Contents

Where Does Engine Coolant Go? A Case Study on a Mercedes-Benz E300 W212

A question many owners of the Mercedes-Benz E300 W212 with the OM651 Engine ask is: “Where does engine coolant go?” Coolant is critical for preventing overheating, lubricating internal water pump seals, and maintaining proper combustion temperatures.

While slight fluctuations in coolant levels may happen due to expansion, evaporation, or topping-up inconsistencies, a consistent or unexplained coolant drop usually means there’s a leak or circulation issue.

In this case study, we’ll look at a Mercedes-Benz E300 W212 that arrived with a dropping coolant level, investigate where the coolant was going, and explain how the issue was successfully diagnosed and repaired.

Symptoms, Causes, and Fixes

| Symptoms | Possible Causes | Recommended Fix |

|---|---|---|

| Coolant level dropping gradually | External leak (pump, hoses, radiator) | Pressure test and replace leaking part |

| Dashboard coolant warning | Coolant pump leak or thermostat housing failure | Inspect system, replace faulty component |

| Engine overheating | Insufficient coolant circulation | Replace coolant pump, bleed system |

| No visible external leaks | Internal leak (head gasket, cylinder head crack) | Inspect for coolant in oil, replace head gasket/block |

| Poor heater performance | Air pockets from improper bleeding | Bleed system using correct vacuum procedure |

The Case: Mercedes-Benz E300 W212 Coolant Drop

Vehicle Details

- Model: Mercedes-Benz E300 W212

- Engine: OM651

- Complaint: Coolant level in the expansion tank was dropping without explanation.

The owner was concerned about potential overheating and wanted to know: Where does engine coolant go if there are no visible leaks?

Step 1: Diagnostic Check

The technician first performed a complete diagnostic scan with Mercedes-Benz STAR/Xentry.

- – No fault codes were stored.

- – Cooling system sensors appeared normal.

However, the coolant level drop confirmed a physical issue not detected by the ECU.

Step 2: Coolant Pressure Test

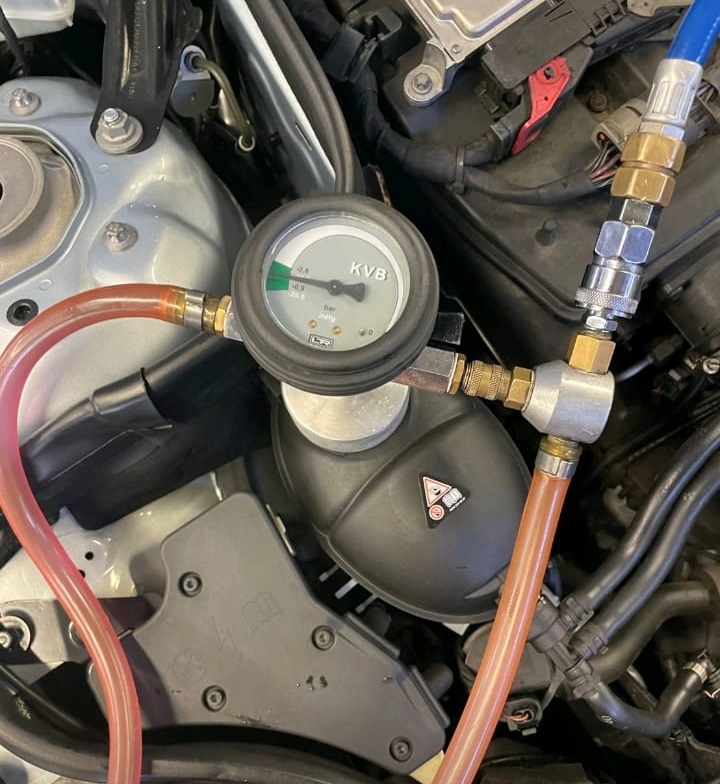

A coolant system pressure test was carried out:

- – When the system was pressurized, the gauge on the manometer began to lose pressure.

- – This confirmed a leak existed somewhere in the system.

Although no obvious external leak was initially visible, this test ruled out evaporation as the cause.

Step 3: Inspecting the Cooling System

The technician inspected:

- – Radiator & hoses → no leaks.

- – Expansion tank → intact, cap sealing correctly.

- – Heater core area → dry, no odor of coolant.

Finally, a small but significant leak was discovered in the engine coolant pump housing.

Answer to the question “Where does engine coolant go?”

In this case, it was escaping from a leak in the water pump.

Step 4: Repair and Solution – Replacing the Coolant Pump

The faulty pump was replaced as follows:

1- Drain Coolant System: prevented spillage and contamination.

2- Remove Old Coolant Pump: disconnected hoses, electrical connections, and mounting bolts.

3- Install New OEM Mercedes Pump: torqued bolts to factory specification.

4- Reconnect and Seal System: ensured no loose hoses or gaps.

After installation, the cooling system required bleeding to remove airlocks.

Step 5: Cooling System Bleeding

Modern Mercedes engines, including the OM651, require vacuum-assisted bleeding to avoid air pockets.

Cooling system bleeding is the process of removing trapped air from the vehicle’s cooling system after draining, refilling, or replacing the coolant. Air pockets, or airlocks, can get trapped in the system during these procedures, which can disrupt the flow of coolant and lead to overheating or inefficient engine cooling.

Steps in Mercedes-Benz Cooling System Bleeding:

1. Park the Vehicle: Ensure the vehicle is on a level surface to prevent air from getting trapped in high points of the cooling system.

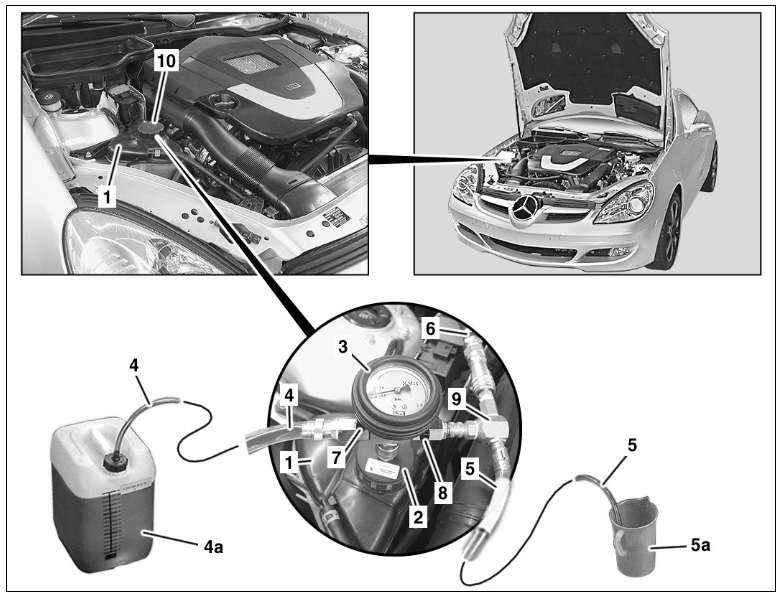

2. Place the coolant reservoir (4a) of the radiator vacuum filling device at the same height as the coolant expansion tank (1).

3. Unscrew the cooling system cap (10) and screw the test cap (2) onto the coolant expansion tank (1).

4. Insert the control unit (3) onto the test cap (2).

5. Insert the Venturi nozzle (9) onto the control unit (3).

6. Close the drain valve (8) and the inlet valve (7).

7. Connect the coolant supply hose (4) to the coolant reservoir (4a). To prevent air from being drawn into the coolant reservoir (4a) and to ensure traceability of the engine cooling system capacity in the vehicle, always fill the coolant reservoir (4a) completely.

8. Immerse the air vent hose (5) into an empty container (5a).

9. Connect the compressed air hose (6) to the Venturi nozzle (9) and supply it with pressure. There must be an overpressure of at least approximately 8 bar in the compressed air supply so that the Venturi nozzle (9) can generate sufficient vacuum.

10. Open the drain valve (8). A vacuum is then produced in the engine cooling system.

11. Open the inlet valve (7) until the supply hose (4) is filled with coolant, and then close the inlet valve (7).

12. Close the drain valve (8) when the display on the control unit (3) is in the green range.

13. Remove the compressed air hose (6) from the Venturi nozzle (9) and check if the vacuum remains stable for 30 seconds. If not: => Check the condition of the hoses and connections, repair them if necessary, and generate the vacuum again.

14. Seal the inlet valve (7) and the drain valve (8).

This ensured proper circulation and prevented overheating due to trapped air.

Step 6: Test Drive & Confirmation

After the repair and bleeding:

- – A test drive was carried out.

- – Coolant level remained stable.

- – No warning lights or leaks detected.

- – Engine temperature stayed within normal operating range.

Problem resolved: the coolant pump was the culprit.

Conclusion

This Mercedes-Benz E300 W212 OM651 case study highlights how coolant can “disappear” from the system without visible leaks.

- – Root cause: Small leak at coolant pump.

- – Solution: Replace coolant pump + bleed system.

- – Result: Coolant level stabilized, overheating prevented.

Key takeaway: If your coolant level keeps dropping with no visible signs, it’s not normal. Always check the pump, radiator, hoses, thermostat housing, and internal leaks such as head gaskets.

More Mercedes Cooling System Resources

Want to explore more causes, symptoms, and repair tips for coolant leaks, overheating, and contamination?

Learn more about Mercedes cooling system faults in our full Cooling System Guide.

Why It’s Important to Bleed the Cooling System

Bleeding is essential after coolant replacement because air pockets can disrupt circulation, causing:

- – Overheating.

- – Poor heater performance.

- – Risk of head gasket damage.

Following manufacturer bleeding procedures ensures reliable cooling and engine safety.

FAQs

Q1: Where does engine coolant go if there are no visible leaks?

It could be leaking from the water pump, internal head gasket, heater core, or radiator cap.

Q2: Is bleeding the cooling system necessary?

Yes, bleeding removes airlocks that disrupt coolant flow and prevent proper cooling.

Q3: Can coolant evaporate naturally?

Yes, but only in very small amounts. A noticeable drop is usually a leak.

Q4: How much does it cost to replace a Mercedes-Benz coolant pump?

Typically $600–$1,000 depending on labor and OEM parts.

Q5: What happens if I ignore a coolant drop?

You risk engine overheating, head gasket failure, and severe engine damage.

Author

Written by: Mercedes Expert

Automotive Technical Trainer & Mercedes-Benz Diagnostic Specialist

With years of hands-on experience repairing and diagnosing Mercedes-Benz vehicles, specializes in case-study-based troubleshooting guides that blend workshop accuracy with educational clarity.

Last Updated: August 2025

— Salim, Mercedes Expert

Independent specialist in Mercedes-Benz diagnostics, CAN Bus analysis, troubleshooting case studies, and EV systems.

Leave a Reply