Table of Contents

Engine Rebuild Case Study: Mercedes-Benz C Class W204 (M271 Engine)

In the world of automotive maintenance and repair, few jobs are as intricate and rewarding as an engine rebuild. For many drivers, engine rebuilds are a last resort after wear and tear have taken their toll on a vehicle’s performance.

Today, we will dive into an interesting case study involving a Mercedes-Benz C Class W204 equipped with the M271 Engine. This particular vehicle had a customer complaint about a rattle sound during cold starts, which eventually led to a complete engine rebuild.

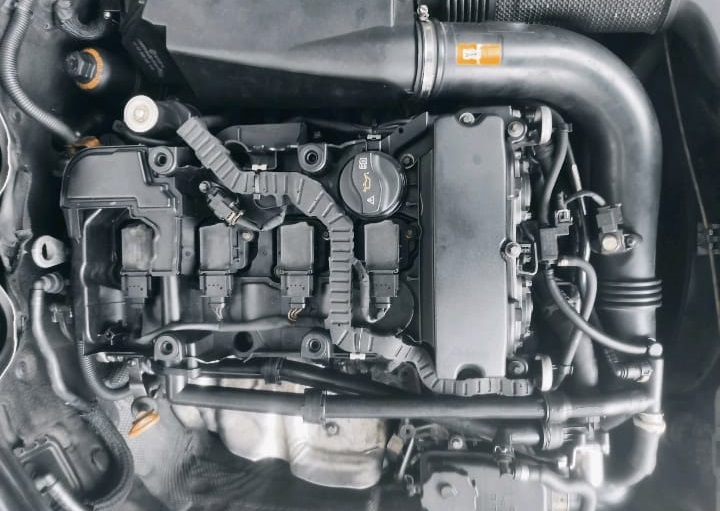

Vehicle Overview: Mercedes-Benz C Class W204 with M271 Engine

The Mercedes-Benz C Class W204, powered by the M271 Engine, is known for its balance of performance and efficiency. However, as with many high-performance engines, age and lack of maintenance can lead to issues like rattling noises, especially at cold starts. These noises often indicate problems with the engine’s timing components, requiring immediate attention before more severe damage occurs.

Customer Complaint: Rattle Sound at Cold Start

The customer initially came into the workshop complaining of a persistent rattle sound during cold starts. After an initial inspection, the sound was attributed to a worn-out timing chain or timing components, a known issue in high-mileage M271 engines. Timing issues are not uncommon, but ignoring them can lead to catastrophic engine failure.

Diagnosis Process and Decision to Rebuild

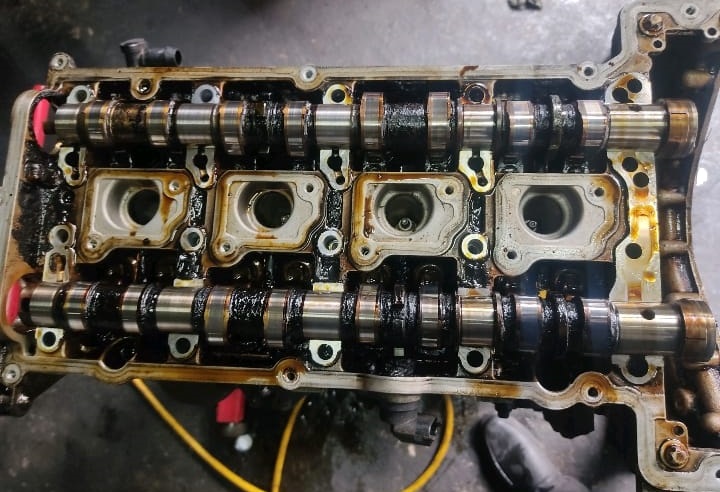

Upon further inspection, we decided to perform a thorough diagnostic test on the engine. Our first course of action was to perform a timing job. However, when we removed the valve cover, we encountered a significant problem: oil sludge had built up all over the engine components.

Why Oil Sludge is a Red Flag

Oil sludge forms when the engine oil breaks down due to contamination, oxidation, or infrequent oil changes. This thick sludge restricts the movement of vital components, leading to increased wear and eventual engine failure.

In this case, the oil sludge was so pervasive that a simple timing job would have been ineffective. The sludge buildup had already compromised the engine’s internals, meaning that a more thorough solution was necessary: a complete engine rebuild.

Recommending an Engine Rebuild

After explaining the situation to the customer, we advised against performing the timing job alone. With sludge buildup, even replacing the timing chain would be a short-term fix. Instead, we recommended a full engine rebuild, which would allow us to thoroughly clean the engine components and replace any worn parts. The customer understood the severity of the situation and gave us approval to proceed with the engine rebuild.

The Engine Rebuild Process

An engine rebuild is a meticulous process that involves disassembling the engine, inspecting each component, cleaning or replacing worn parts, and reassembling the engine to factory specifications. Here’s a breakdown of what was done:

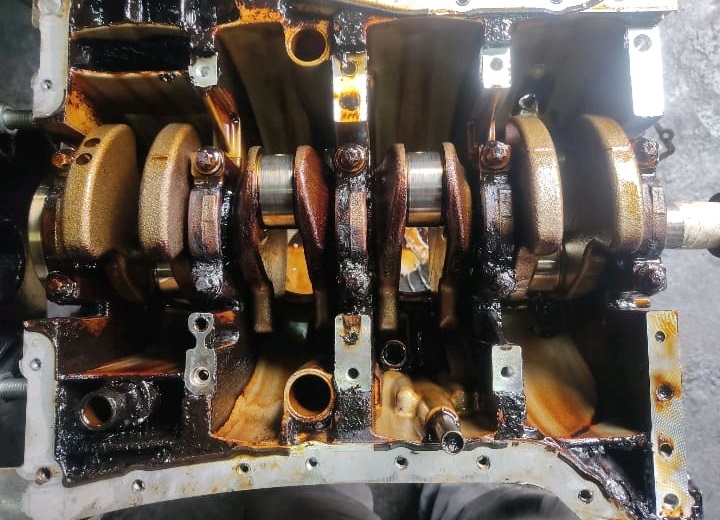

1. Engine Disassembly: The engine was carefully disassembled, with special attention to the timing components, pistons, valves, and camshafts. Each part was inspected for wear and tear.

2. Cleaning the Sludge: All traces of oil sludge were meticulously removed. Cleaning the internals of the engine is crucial to ensure proper oil flow and to prevent future buildup.

3. Replacing Worn Components: Several components, including the timing chain, tensioners, and worn gaskets, were replaced. Additionally, we replaced the oil pump to ensure efficient oil circulation post-rebuild.

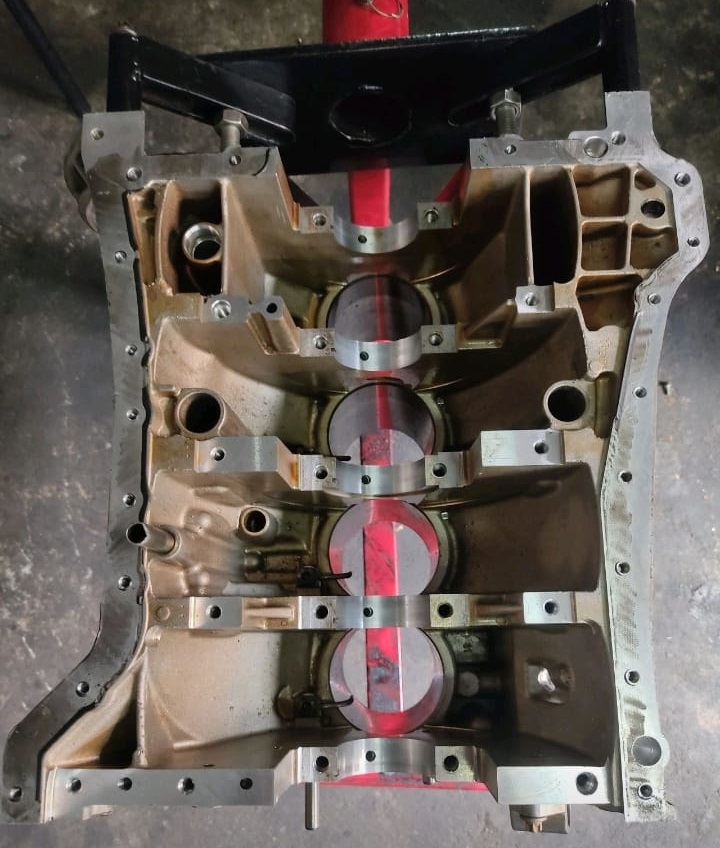

4. Reassembly: After cleaning and replacing the necessary parts, the engine was reassembled according to factory specifications, ensuring that all tolerances and clearances were accurate.

5. Testing: Once the engine rebuild was complete, the vehicle underwent a series of tests to ensure that the engine was operating smoothly and that the rattle sound had been resolved.

Customer Satisfaction Post-Engine Rebuild

Upon completion of the engine rebuild, the customer was able to drive their Mercedes-Benz C Class W204 with renewed confidence. The rattle sound was completely gone, and the engine performance had dramatically improved. With a freshly rebuilt engine, the vehicle was now in optimal condition, providing a smoother and more responsive driving experience.

Conclusion

This case study highlights the importance of addressing engine issues promptly, especially when warning signs like a rattle sound during cold starts appear. While a timing job might have initially seemed like the solution, discovering oil sludge led to a more comprehensive engine rebuild. The decision to go for a full engine rebuild ultimately resulted in a much better outcome for the customer, ensuring long-term engine health and performance.

Engine rebuilds, though complex, offer the opportunity to bring a tired engine back to life. In this case, the Mercedes-Benz C Class W204 with its M271 engine is now performing as it did when new, thanks to a thorough and well-executed rebuild process.

Rebuild Engines

What is a Rebuilt Engine?

A rebuilt engine refers to an engine that has been disassembled, cleaned, inspected, and repaired using new or reconditioned components. The purpose of rebuilding an engine is to restore it to its original operating condition or improve its performance and longevity.

A rebuild can address significant internal issues such as wear and tear on key parts like pistons, crankshafts, bearings, and timing components, all while maintaining the original engine block.

Common Reasons for Rebuilding an Engine

Excessive Wear: Over time, engine components like piston rings, bearings, and valves experience wear due to friction and heat. Rebuilding the engine replaces these worn parts to restore performance.

Oil Sludge or Contamination: Poor maintenance, low-quality oil, or infrequent oil changes can cause sludge buildup or contamination inside the engine, leading to reduced performance and eventual failure.

Overheating: Frequent overheating can damage essential components like the head gasket, pistons, and valves. A rebuild can rectify damage caused by overheating.

Loss of Power: If the engine loses compression or starts consuming excessive oil, it’s often a sign that the internal components have degraded. Rebuilding helps restore the engine to a like-new condition.

Failed Parts: Issues such as a broken timing chain, faulty oil pump, or cracked cylinder head can lead to the need for a rebuild to ensure the engine operates properly again.

The Engine Rebuild Process

1. Disassembly: The engine is removed from the vehicle and fully disassembled, allowing each component to be inspected.

2. Inspection and Cleaning: Components such as the engine block, crankshaft, pistons, camshafts, and valves are cleaned and checked for damage. This step helps identify which parts need replacement or reconditioning.

3. Replacement of Worn Parts: Parts that show signs of wear or damage, such as piston rings, bearings, seals, and gaskets, are replaced with new or reconditioned parts.

4. Machining: Sometimes the engine block, crankshaft, or cylinder heads need machining to ensure they meet factory tolerances. This can include honing the cylinders, resurfacing the heads, or grinding the crankshaft.

5. Reassembly: The cleaned and repaired components are reassembled, following manufacturer specifications for torque and clearance.

6. Testing: After reassembly, the engine is tested for compression, oil pressure, and overall performance to ensure that it runs smoothly and efficiently.

Benefits of Rebuilding an Engine

Cost-Effective: Rebuilding an engine is typically more affordable than purchasing a new engine or a full engine replacement, especially for high-value or rare vehicles.

Extended Lifespan: A properly rebuilt engine can significantly extend the life of a vehicle, allowing it to perform as new or better, depending on the parts used.

Environmental Impact: Rebuilding an engine can be more environmentally friendly than replacing an engine entirely, as it reduces waste and recycles many of the original engine components.

Customization Opportunities: During a rebuild, there’s an opportunity to upgrade parts for better performance or durability, such as using forged pistons or high-performance bearings.

Signs Your Engine Might Need Rebuilding

1. Knocking or Rattling Sounds: Persistent noises coming from the engine, such as knocking, could indicate worn bearings or other internal issues.

2. Loss of Compression: If your engine has trouble starting, lacks power, or consumes too much oil, it might be due to low compression, which is often a sign that an engine rebuild is needed.

3. Excessive Exhaust Smoke: Blue or white smoke coming from the exhaust can indicate that oil is burning in the engine, a problem that can be solved with a rebuild.

4. Frequent Overheating: An engine that repeatedly overheats may have internal damage, requiring a rebuild to fix the root cause.

5. Excessive Oil Consumption: If you find yourself adding oil regularly between changes, this could be due to worn piston rings or valve seals issues that a rebuild can address.

Rebuilt vs. Remanufactured Engines

- Rebuilt Engine: Rebuilt engines are disassembled and inspected, with damaged parts replaced. They are restored to working condition but may still contain some original parts.

- Remanufactured Engine: In contrast, a remanufactured engine is returned to the original factory specifications, with most parts replaced or reconditioned to “like-new” standards. These engines often undergo more rigorous testing and offer warranties similar to new engines.

Conclusion

Rebuilding an engine is a comprehensive process that can breathe new life into a vehicle. Whether it’s done to address specific issues like worn timing components or to extend the overall lifespan of a beloved vehicle, an engine rebuild offers both economic and performance benefits. With proper care and high-quality parts, a rebuilt engine can perform as well, if not better, than a brand-new one.

Leave a Reply