Table of Contents

Mercedes E300 Hybrid Not Starting ; Case Study and Complete Diagnostic Guide

When faced with a Mercedes E300 Hybrid Not Starting, it can be a complex challenge especially in vehicles where traditional diesel systems meet high-voltage hybrid components.

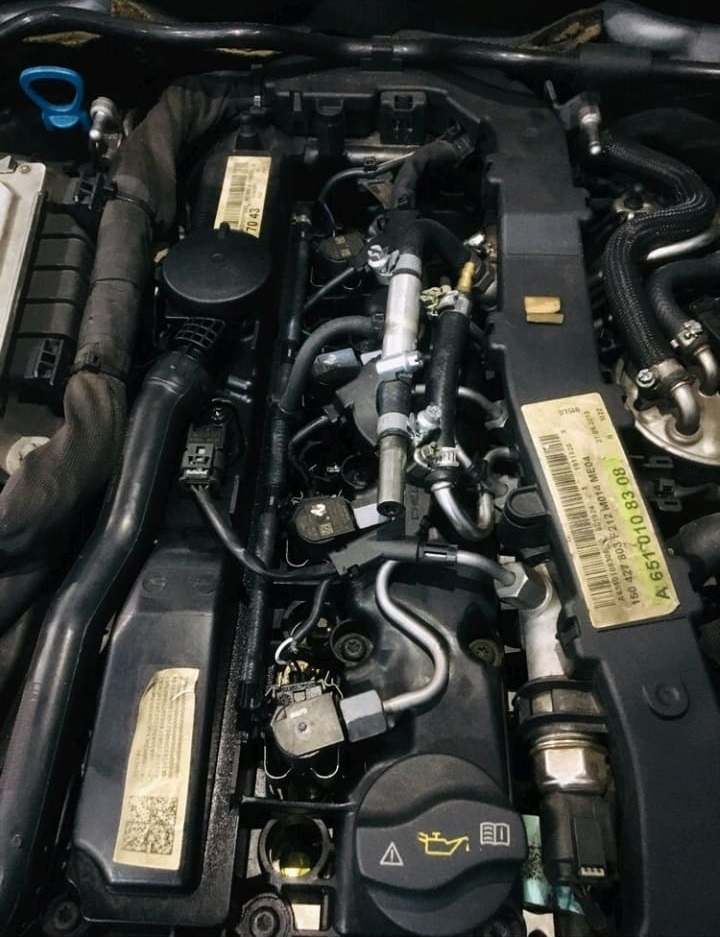

This detailed case study of a Mercedes-Benz E300 W212 equipped with the OM651 diesel engine and hybrid system demonstrates how precise diagnostics and a systematic approach led to identifying and resolving a no-start issue that involved both the fuel system and the hybrid battery management system.

Vehicle Overview

| Model | Mercedes-Benz E300 W212 (Hybrid) |

|---|---|

| Engine | OM651 Diesel Engine with Hybrid Drive |

| Complaint | Vehicle won’t start displays hybrid-related warning |

| Systems Involved | Engine Control Module (ECM), Battery Management System (BMS) |

Customer Complaint

The customer brought in their Mercedes-Benz E300 Hybrid after repeated attempts to start the vehicle failed.

The engine would crank but not fire, and the dashboard displayed hybrid system errors.

This is a classic example of a hybrid no-start issue, where both electrical and mechanical systems must be examined in parallel.

Step 1: Verification of the Problem

Upon receiving the vehicle, technicians verified the concern by attempting to start the engine.

The starter engaged normally, but the engine failed to ignite, confirming a true no-start condition.

Two primary systems were immediately suspected:

- 1. Fuel delivery system : insufficient fuel pressure or restricted flow.

- 2. High-voltage hybrid battery system : possible low state of charge or communication error.

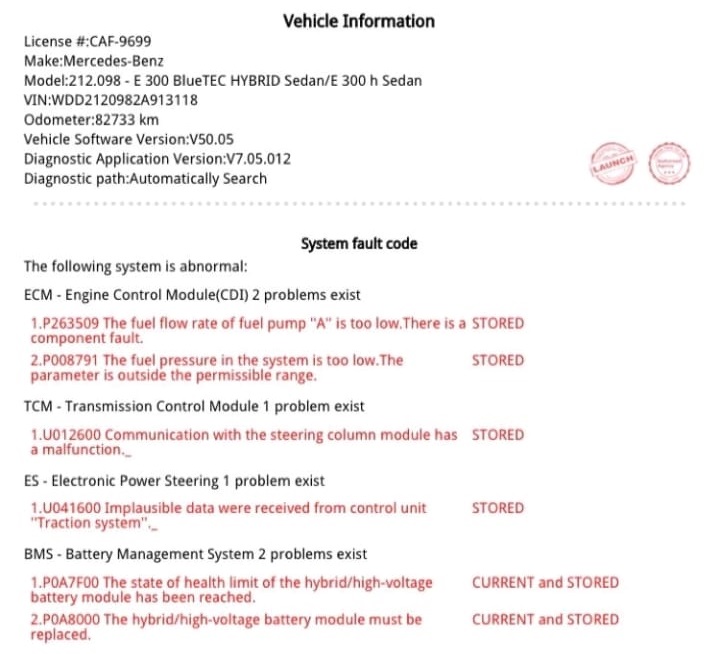

Step 2: Fault Code Analysis Using XENTRY

The Mercedes-Benz XENTRY diagnostic tool was connected to the vehicle to read live data and fault codes.

Results from two key modules ECM (Engine Control Module) and BMS (Battery Management System) revealed the following:

Engine Control Module (ECM) Faults

| Code | Description |

|---|---|

| P263509 | Fuel pump “A” flow rate too low stored component fault |

| P008791 | Fuel pressure too low parameter outside permissible range |

Battery Management System (BMS) Faults

| Code | Description |

|---|---|

| P0A7F00 | State of health limit of hybrid/high-voltage battery reached |

| P0A8000 | Hybrid/high-voltage battery module must be replaced |

These fault codes pointed toward two possible concurrent issues: a fuel delivery restriction and battery degradation within the high-voltage hybrid system.

Step 3: Fuel System Inspection

Given that the ECM reported low fuel pressure and flow, technicians began by visually inspecting the fuel rail, lines, and pump connections.

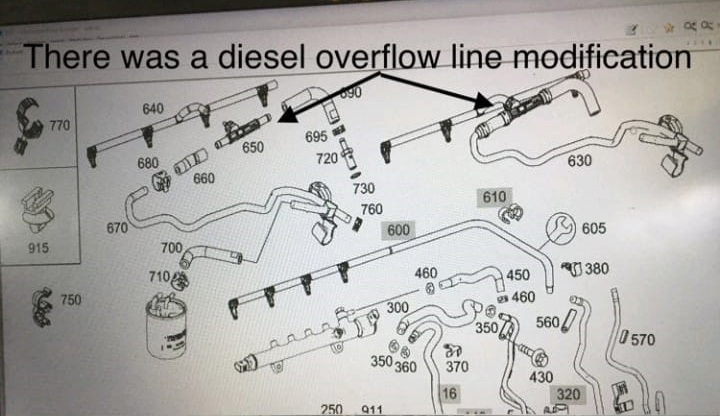

Upon inspection, a key anomaly was discovered:

The diesel injector overflow line valve had been incorrectly modified during a previous repair, disrupting normal fuel return flow and pressure regulation.

This modification directly restricted fuel flow, preventing the engine from receiving adequate pressure during cranking one of the main causes of Mercedes E300 Hybrid not starting in this case.

Step 4: Repair Actions

To restore proper system functionality, technicians performed the following corrective steps:

- 1. Replaced the fuel pump to ensure optimal fuel pressure delivery.

- 2. Removed the incorrect modification on the injector overflow valve.

- 3. Reconnected and sealed all fuel lines according to OEM routing and pressure specifications.

- 4. Cleaned the fuel rail and pressure sensor to eliminate potential contaminants.

After reassembly, the system was re-pressurized, and XENTRY was used to monitor live fuel pressure during cranking.

Result:

Fuel pressure values returned to within normal range, confirming that the delivery problem had been resolved.

Step 5: Addressing Hybrid Battery Faults

With the fuel system restored, focus shifted to the Battery Management System (BMS) fault codes.

The codes P0A7F00 and P0A8000 typically indicate a reduced state of health (SOH) or capacity degradation in the hybrid battery module.

Diagnostic Insight:

- – Hybrid batteries in the W212 E300 serve as assistive power units during cranking and regenerative braking.

- – A failing module can reduce power support to the Integrated Starter Generator (ISG) or inverter, which may trigger start inhibition.

In this case, after fixing the fuel flow problem, the hybrid system was rechecked:

- – Voltage output from the HV battery was within permissible range.

- – No isolation faults were detected.

- – The BMS codes were stored, not active, suggesting temporary degradation rather than permanent failure.

Decision:

The hybrid battery was monitored for performance rather than immediately replaced.

The customer was advised to return for follow-up inspection if warnings reappeared.

Step 6: Testing and Verification

After completing repairs, the ECM and BMS fault codes were cleared, and the vehicle was restarted.

Outcome:

- – Engine started on the first attempt.

- – Fuel rail pressure remained steady during idle and acceleration.

- – No further hybrid or fuel system warnings appeared.

- – Start-stop hybrid functions operated normally during road test.

The Mercedes E300 Hybrid was fully operational and ready for delivery.

Root Cause Summary

| System | Fault | Effect | Resolution |

|---|---|---|---|

| Fuel Delivery | Modified injector overflow valve causing pressure restriction | Engine failed to start due to insufficient fuel | Restored original valve configuration and replaced fuel pump |

| Hybrid Battery | Reduced state of health (SOH) | Potential loss of hybrid support power | Monitored BMS status after confirming successful start |

Technical Insights for Hybrid Diesel Systems

Hybrid diesel models like the E300 W212 OM651 integrate mechanical and electrical systems in a tightly synchronized process.

Key points for diagnosing hybrid no-start conditions:

- – Check low-voltage (12V) system first: The hybrid system cannot initialize with a weak 12V supply.

- – Monitor 48V or HV line voltage stability: Voltage dips can prevent the ISG from cranking.

- – Always confirm fuel pressure before suspecting hybrid components.

- – Use OEM diagnostic tools (XENTRY) to monitor BMS SOH and isolate genuine battery degradation.

Preventive Maintenance Tips

| Action | Purpose |

|---|---|

| Perform fuel pressure tests during routine service | Detect weak pumps or pressure leaks early |

| Avoid unauthorized modifications to fuel lines or valves | Prevents flow restrictions and pressure faults |

| Check hybrid battery SOH annually with XENTRY | Tracks degradation trends |

| Keep the 12V auxiliary battery in good condition | Ensures proper initialization of hybrid components |

| Drive the hybrid regularly | Prevents battery discharge and keeps systems balanced |

Final Outcome

After completing the fuel system restoration and verifying hybrid battery performance, the Mercedes E300 Hybrid started successfully and performed normally.

This case reinforces the importance of step-by-step diagnosis when dealing with hybrid no-start issues.

By focusing on both mechanical (fuel) and electrical (battery) systems, technicians avoided unnecessary part replacements and restored reliability efficiently.

Related Diagnostic Resource

If you’re facing similar starting problems, explore our full troubleshooting hub:

Mercedes No Start Issues: Causes, Fixes & Case Studies : a complete guide covering electrical, fuel, and ECU-related no-start scenarios across multiple Mercedes models.

FAQ : Mercedes E300 Hybrid Not Starting

Q1: Why does my Mercedes E300 Hybrid not start even if it cranks?

Because hybrid systems require both proper fuel pressure and battery communication. A fault in either system can block ignition authorization.

Q2: Can a weak hybrid battery stop the engine from starting?

Yes. The high-voltage battery supports cranking via the hybrid system. If degraded or disconnected, it can prevent startup.

Q3: Should I replace the hybrid battery immediately after a fault code?

Not always. Stored codes may result from temporary voltage drops always verify with live data and battery health tests before replacement.

Author Bio

Written by Mercedes Expert

With years of hands-on experience diagnosing and repairing Mercedes-Benz systems, he brings technical depth and practical case studies to help car owners, technicians, and enthusiasts troubleshoot complex automotive issues. His work focuses on clear repair guides, OEM-level procedures, and knowledge-sharing to empower both professionals and drivers.

Last update: October 2025

Leave a Reply